SPECTROSCOPY: Laser spectroscopy measures motor oil consumption

STEFAN SELLMEIER, EDUARDO ALONSO, ULRICH BOESL, CHRISTIAN MENHARD, REINHARD KELNBERGER, and HEINZ BACHER

With exhaust gas emission limits and environmental protection regulations becoming increasingly strict, development engineers need to strike a balance when designing new motors. While lowering automotive emissions and fuel consumption as much as possible, they must also ensure high reliability, ease of maintenance, and durability of the engine. Knowing the exact motor oil consumption at various operating points is an indispensable tool in reaching these goals.

Among the parameters that decisively influence motor performance are the number and location of the piston rings or the type and surface quality of the cylinder wall. To optimize these parameters, it is very important to understand oil consumption.

The most common method for measuring motor oil consumption is gravimetric determination, in which the motor is filled with a defined amount of motor oil and operated at constant rotation speed and load over many hours. Subsequently, the motor oil is drained and weighed. This procedure is very time consuming and costly, and does not allow for any dynamic measurements.

More than 90% of motor oil consumption is caused by the evaporation of the motor oil film from the inner cylinder walls and subsequent emission into the exhaust gas. Hence, all modern approaches of analyzing motor oil consumption focus on the trace detection of motor oil in the exhaust gas. This is a very demanding analytical task because the concentrations that are to be measured are very low and the mixture of substances is very complex.

The Technical University of Munich in collaboration with BMW Group and InnoLas Laser have developed a procedure with which motor oil consumption can be measured quickly, exactly, and reliably. It involves the use of sulfur as a motor oil indicator, minimal traces of which are detected in the exhaust gas. This kind of motor oil consumption analytics is possible since the introduction of sulfur-free (or rather low-sulfur) fuel.

The challenge is that the sulfur is bound in many different chemical compounds. To effectively detect them, all sulfur-containing motor oil components must be transformed into easily detectable SO2. There were several previous methods to detect SO2,1 but all of them lacked the necessary sensitivity for sulfur in the parts-per-billion (ppb) range.

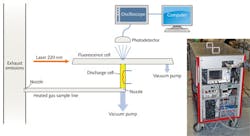

The novelty of the procedure developed by our research team is: 1) converting sulfur containing molecules into SO2 in a small gas discharge cell; 2) detecting the SO2 by a special method of laser-induced fluorescence (involving laser spectroscopy of SO2)2; and 3) employing a newly developed, compact ultraviolet (UV) laser with tunable wavelength.

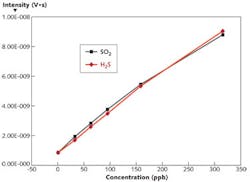

This method enables the very sensitive (<20 ppb), fast (<2 s), and reliable detection of sulfur bound in molecules via SO2 formed by complete pyrolysis of sulfur-containing exhaust gases (see Fig. 1). A small mass spectrometer or a cavity ring-down absorption cell could be used to measure other motor-specific or added trace substances and thereby considerably increase the range of application of the new method.Sulfur oxidation and detection

The total oxidation of sulfur in the exhaust gas to SO2 is a crucial step in this method. In conventional procedures, a high-temperature furnace is employed for the thermal oxidation of the sulfur. In our method, oxidation is performed by means of a non-thermal plasma. The advantages become especially apparent in the oxidation of polycyclic aromatic hydrocarbons, which are difficult or impossible to completely oxidize thermally. In the implemented discharge, however, they can be completely degraded, even at low discharge currents.

The highly sensitive detection of the SO2 is difficult because many compounds that could interfere with the measurement are present in very high concentrations in the exhaust gas. Laser-induced fluorescence is used as the principle of measurement, with excitation of the gaseous mixture performed by a tunable UV laser. High selectivity is achieved by rapidly switching the laser between two different wavelengths, rendering the measurement insensitive to nearly all other substances that are present in the exhaust gas (or rather their fluorescence behavior). Residual cross-sensitivity with nitric oxide—which absorbs and fluoresces at similar wavelengths to SO2—is suppressed by exploiting the large difference in fluorescence lifetimes of both substances.

Finally, the design of the discharge cell and the gas flow management from discharge to fluorescence cell enable the elimination of negative effects. These are primarily memory effects that arise from the deposition and subsequent re-emission of trace substances in the gas flow system and cause a distortion of the measurement results. A schematic of the prototype setup is shown in Fig. 2.Measurements at the motor test facility

Following good results in the laboratory, a mobile prototype system was developed for measurements at motor test facilities. Initially, an Nd:YAG-pumped dye laser was used. It was replaced by an optical parametric oscillator (OPO) laser system developed by Innolas Laser.

An actively pumped gas inlet with a separate nozzle for fresh air supply was integrated into the mobile testing device. This addition ensures the complete oxidation of hot, particle-containing and especially oxygen-deficient motor exhaust gases. The original prototype enabled very high detection sensitivity and selectivity during oil consumption measurements on a six-cylinder gasoline engine in cooperation with the Landshut University of Applied Sciences (Landshut, Germany).

It was even possible to resolve the effects of an oil change-the switch from old to fresh motor oil-on the motor oil consumption. Measurements under industrial conditions at a BMW Group test facility are underway (see Fig. 2 inset).

Laser system

The laser source is of particular importance for the project. A tunable light source in the deep UV (215–225 nm) is required and must emit several 100 µJ of collimated radiation. The radiation is then directed into the measurement chamber, inducing molecular excitation and fluorescence.

There are relatively few laser sources available in this range of wavelengths. Excimer lasers are capable of emitting within this range; however, they are limited to discrete wavelengths (e.g., 193 nm, 248 nm). Therefore, only two types of systems are eligible for this type of experiment: frequency-doubled dye lasers and OPOs.

Dye lasers. At the first stage of development, a dye laser was employed. While it had the advantage of emitting a very narrowband laser light, it also has high maintenance and adjustment requirements. At the selected wavelength, the dye needs to be renewed after an operating time of only 10 hr. This, in turn, is time consuming and requires expertise as well as the handling of dangerous solvents.

Furthermore, a complex adjustment of the laser is necessary before (e.g., at severe temperature fluctuations) and partly also during the measurements. Finally, such a laser system is very bulky and not suitable for a compact mobile measuring device. All of these factors render the dye laser unsuitable in a measuring device that should be robust, low-maintenance, and usable after minimal training of the service personnel at a motor test bench.

Optical parametric oscillators. As an alternative, InnoLas Laser developed an OPO for the prototype. Unlike the dye laser, the OPO is based on crystal-optical components, enabling reliable, uncomplicated operation. The OPO consists of three modules: 1) a compact, flashlamp-pumped Nd:YAG laser with a repetition rate of 20 Hz; 2) crystals for second and third harmonic generation to convert the laser wavelength from 1064 to 355 nm; and 3) the OPO unit with an integrated frequency doubler for an output wavelength between 215 and 225 nm (see Fig. 3).The three modules are housed in a monolithic case, which renders the radiation source insensitive to external influences. The first two modules are already being employed in a large number of lasers; the OPO section was developed especially for this project. Specifically, an OPO resonator with a Type II BBO crystal was used, which converts the pump radiation (355 nm) simultaneously into the signal (430–450 nm) and idler radiation (1680–2000 nm).

By rotating the BBO crystal, the radiation can be continuously tuned to the required wavelength. The signal radiation is converted into the UV range using another rotatable BBO crystal inside the resonator, which is also rotatable. The crystal rotation occurs at such high speeds that the emission wavelengths for each single pulse can be freely selected.

A potential problem was at first seen in the fact that the spectral width of the OPO radiation surpasses that of the dye laser by more than a factor of 10. Experiments have shown, however, that this does not reduce the sensitivity and selectivity of the measuring procedure.

The mobile measuring prototype is compact (the light source is 560 × 280 × 91 mm) with nearly maintenance-free operation (only the flashlamp needs to be replaced after 20 million light pulses). A further advantage is the quick and precise tunability of the OPO, which results in a significantly increased velocity in differential measurements (i.e., the fluorescence signals of two differing wavelengths are subtracted from one another).

As a result of this project, a new method was developed for measuring the motor oil consumption quickly, precisely, and reproducibly. In combination with a compact laser system, it can be developed further into the serial production stage. The measuring system is tailored to the specific analytical task of measuring motor oil consumption, although it may be suitable for more advanced tasks, including the detection of motor oil emissions in aerosol form by a cavity ring-down absorption cell or the rapid chemical analysis of other trace substances in the exhaust gas by integration of a miniaturized time-of-flight mass spectrometer. Thus, after this prototype is developed into a commercial system a new tool for motor development will be available to engineers.

ACKNOWLEDGMENT

This project has been supported by the Bavarian Research Foundation (BFS) project number AZ-795-07.

REFERENCES

1. MEXA-1170SX, Horiba online (2011); http://bit.ly/S7Fysk.

2. Y. Matsumi, H. Shigemori, and K. Takahashi, "Laser-induced fluorescence instrument for measuring atmospheric SO2," Atmospheric Environment, 39, 3177 (2005).

Dr. Stefan Sellmeier, Prof. Dr. Ulrich Boesl, and Eduardo Alonso are at Technische Universität München, Munich, Germany. Christian Menhard and Reinhard Kelnberger are with InnoLas Laser, Kralling, Germany. Heinz Bacher is with BMW Group, Munich, Germany. Contact: Reinhard Kelnberger, [email protected].