High-Power UV Lasers: Tunable ultraviolet burst-mode laser system produces high-energy pulses

NAIBO JIANG, WALTER R. LEMPERT, MIKHAIL N. SLIPCHENKO, JOSEPH D. MILLER, TERRENCE R. MEYER, AND JAMES R. GORD

While planar laser-induced-fluorescence (PLIF) imaging of aerodynamic and combustion flows has developed enormously since its inception in the early 1980s, the ability to directly capture the dynamics of unsteady and/or turbulent phenomena at high speed has been constrained by the difficulty of generating high-repetition-rate, broadly wavelength-tunable ultraviolet radiation with sufficient individual pulse energy. However, sources with all these characteristics have now been made possible by advances in the development of Nd:YAG-pumped optical-parametric-oscillator (OPO) systems operated in what has come to be known as “pulse-burst” mode. In combination with sum-frequency mixing, such systems have produced demonstrated output of around 0.5 or 1.0 mJ per pulse at 226 or 313 nm, respectively—sufficient to enable instantaneous nitric oxide (NO) and hydroxyl (OH) imaging at repetition rates as high as 250 kHz.

While reported burst-mode Nd:YAG systems differ in detail, they share certain basic characteristics. Specifically, reported systems typically use a low-power (on the order of 100 mW) master oscillator (typically Nd:YAG) that is “sliced” into a burst train using either a pair of electro-optic Pockels cells or an acousto-optic deflector. 1-5 In one exception, a repetitively Q-switched diode-pumped Nd:YVO4 laser is used as the master oscillator.6 The burst train is then amplified in a series of flashlamp-pumped Nd:YAG amplifiers. Typical reported burst sequences consist of between 8 and 40 pulses, with interpulse spacing as low as 1 μs, and individual pulse duration of between 6 and 25 ns.

Many pulses from one

The burst-mode Nd:YAG system used in our research program is based on the system originally developed by Wu et al.(see Fig. 1). A single-frequency continuous-wave Nd:YAG ring laser serves as the primary oscillator, the output of which is preamplified in a standard double-pass flashlamp-pumped, pulsed Nd:YAG amplifier. While previous systems used fixed, approximately 150 to 300 μs pulse-duration power supplies to drive the lamps, we have recently incorporated a set of commercially available flashlamp drivers (manufactured by Analog Modules, Longwood, FL) so that the preamplified output consists of a single, temporally smooth 0.150 to 2.0 ms pulse, which is then formed into a “burst” train using a custom dual electro-optic Pockels cell “slicer.” Note that a similar, custom-designed variable-pulse-width flashlamp supply will be incorporated into a system currently under development as a source for high-repetition-rate Thompson scattering.6

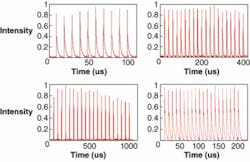

The sliced pulse train is further amplified in a set of four additional flashlamp-pumped Nd:YAG amplifiers, with a stimulated Brillouin scattering (SBS) phase-conjugate mirror (PCM) located between amplifiers 3 and 4. The PCM, which acts as a nonlinear intensity-dependent mirror, serves to eliminate a low-intensity “pedestal” superimposed on the high-intensity burst train, which results from the finite on/off contrast (on the order of 103 to 104) of the Pockels-cell slicer. Similarly, it also serves to reduce the exponential growth of amplified spontaneous emission (ASE) in the forward direction by providing isolation between the first three and final two amplification stages.Three representative burst sequences for the fundamental output at 1064 nm serve as an example of the capabilities of the Nd:YAG pump laser (see Fig. 2). The upper left trace shows a burst of 10 pulses with 10 μs interpulse spacing and with an average energy per pulse of about 85 mJ. The upper right trace shows a burst of 20 pulses with 20 μs spacing and average individual pulse energy of about 230 mJ. At this repetition rate, similar to commercial “double-pulse” Nd:YAG systems, the time interval between the pulses is sufficient to allow partial refilling of the gain prior to the next pulse, resulting in higher and more uniform pulse energy. The lower left trace shows a sequence consisting of 20 pulses at 50 μs spacing. The average individual pulse energy is about 400 mJ/pulse, corresponding to a total extracted energy of 8 J. Note that a relatively high input impedance (about 10 kΩ) was used to capture the bursts in Fig. 2 on a standard digital oscilloscope. The true pulse durations are approximately 6 and 4 ns for the 1064 and 226 nm wavelengths (lower right trace), respectively.

OPO generates tunable radiation

Because PLIF is based on resonant excitation of electronic states of atoms or molecules, broadly wavelength-tunable pulsed UV laser sources are required for time-resolved imaging. Our strategy is to use an OPO for generation of tunable radiation, taking advantage of the fact that the gain decays essentially instantaneously after passage of each pump pulse within the burst.7 It was hypothesized that photobleaching effects, which severely limit the repetition rate of dye lasers, would therefore be minimal, as would thermal effects, because absorption in beta barium borate (BBO) at 355 and 532 nm is quite low. Both 532 and 355 nm OPOs have been used. Type II potassium titanyl phosphate (KTP) is used for second-harmonic generation (SHG) when using 532 nm pumping, whereas third-harmonic generation (THG) uses a pair of noncritically phase-matched Type I LBO crystals. The SHG/THG conversion efficiency is typically about 40% to 50%/33% to 40%, respectively, for individual 1064 nm pump energies in the range of 70 to 90 mJ.

The OPO cavities for 355 and 532 nm pumping are essentially identical.7, 8 For 355 nm pumping, the OPO gain medium consists of a pair of 12-mm-long Type I BBO crystals that are 5 × 7 mm in cross section and arranged in a linear cavity configuration, oriented to provide walk-off compensation between the pump and signal/idler beams. The 10-cm-long cavity uses a broadband high reflector and output coupler coated for 20% to 30% reflectivity in the wavelength range 600 to 850 nm. This low-finesse cavity provides feedback at both the signal and idler wavelengths, with measured round-trip gain exceeding 104 at 18 mJ of 355 nm pump, greatly exceeding the cavity losses for both signal and idler waves. The 355 nm pump beam is coupled into and out of the cavity using a pair of dichroic mirrors, and in some cases is retroreflected. A single-frequency external-cavity diode laser is used to injection seed the cavity at the idler wavelength, resulting in a time-averaged linewidth for both the signal and idler beams of about 300 MHz. Typical OPO conversion efficiency to signal/idler is 20%/15% (by energy), respectively, for 355 nm pump energy of about 30 mJ/pulse or greater. Note that while this design produces narrowband output at all wavelengths, the use of a low-finesse cavity can result in amplitude modulation of the output as the seed laser is tuned.

NO and OH imaging with PLIF

Imaging of NO with PLIF relies on the A 2Σ (v' = 0) ← X 2∏1/2 (v" = 0) electronic transition in the vicinity of 226 nm; this wavelength is produced by sum-frequency mixing of the 622 nm signal output of the 355-nm-pumped OPO with residual output from the 355 nm pump beam. A typical 20-pulse, 10-μs-spacing burst at 226 nm can be seen in the bottom-right trace of Fig. 2. The average individual pump and 622 nm OPO signal energies are 34 and 4.8 mJ, respectively. Mixing with residual 355 nm pump energy of about 11 mJ produced an average single-pulse energy of about 0.5 mJ at 226 nm. To date, PLIF images of NO in laboratory-scale supersonic flows have been obtained at burst frequencies as high as 250 kHz.Imaging of OH with PLIF uses a diode-laser-seeded OPO cavity that is essentially identical to that described above, except that it is pumped at 532 nm.8 Starting with approximately 100 mJ/pulse at 532 nm, the signal output at 763 nm is sum-frequency mixed with the residual 532 nm pump, resulting in about 1 mJ per pulse at 313.526 nm. As an example, a partial series of images (20 total were obtained) from a 1-mm-diameter H2/air diffusion flame obtained at a burst frequency of 25 kHz (frequencies up to 50 kHz have been obtained; see Fig. 3). The temporal evolution of flame structures can be tracked in the image sequence, with turbulent eddies along the interface influencing the mixing process and local combustion chemistry. For example, the evolution of a flame layer is marked with a white circle as it is pinched off from the main reaction zone and subsequently extinguished. These results illustrate the ability of the current system to track turbulent flame phenomena through the relevant time scales of fluid-flame interaction.

Since their inception around 10 years ago, burst-mode laser sources have matured to the point where generation of narrow-linewidth broadly tunable UV radiation, with pulse energy sufficient for PLIF imaging of a wide variety of species, is now available for repetition rates on the order of 250 kHz. It is anticipated that future work will result in systems in the near future capable of operation as high as 1 MHz.

ACKNOWLEDGMENT

The authors acknowledge the U.S. Air Force Research Laboratory, NASALangley Research Center, and NSF for sponsorship of this work.

REFERENCES

1. P. Wu et al., AIAA J. 38, 672 (2000).

2. B. Thurow et al., Appl. Opt. 43, 5064 (2004).

3. M. Wernet and A.B. Opalskii, AIAA-2--4-2184, 24th Aerodynamic Measurement Technology & Ground Testing Conf., Portland, OR, June 28-July 1, 2004.

4. A.L. Kastengren et al., Phys. Fluids 19, 015103 (2007).

5. B. Thurow and A. Satija, AIAA-2006-1384, 44th AIAA Aerospace Sciences Mtg., Reno, NV, Jan, 2004.

6. D.J. Den Hartog et al., accepted for publication in Rev. Sci. Instrum.

7. N. Jiang et al., Appl. Opt. 47, 64 (2008).

8. J.D. Miller et al., Submitted for publication, Opt. Lett.

Tell us what you think about this article. Send an e-mail to [email protected].

NAIBO JIANG is a postdoctoral researcher and WALTER R. LEMPERT is a professor at the Departments of Mechanical Engineering and Chemistry, The Ohio State University, Columbus, OH 43202; e-mail: [email protected]. MIKHAIL N. SLIPCHENKO is a postdoctoral researcher, JOSEPH D. MILLER is a graduate student, and TERRENCE R. MEYER is an assistant professor at the Department of Mechanical Engineering, Iowa State University, Ames IA 50011; JAMES R. GORD is principal research chemist at the Air Force Research Laboratory, Propulsion Directorate, Wright-Patterson AFB, OH 45433.

![FIGURE 3. Ten (of a total of twenty) OH-PLIF images were obtained from an atmospheric-pressure turbulent H2/air diffusion flame at a 25 kHz repetition rate [8]. FIGURE 3. Ten (of a total of twenty) OH-PLIF images were obtained from an atmospheric-pressure turbulent H2/air diffusion flame at a 25 kHz repetition rate [8].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/01/th_0808lfw02f3.png?auto=format,compress&fit=max&q=45?w=250&width=250)