Microresonator generates ultrafast optical frequency combs for sensing and communications

West Lafayette, IN--Researchers at Purdue University and the National Institute of Standards and Technology (NIST) have created an on-chip microresonator that converts CW laser light into optical frequency combs of ultrafast pulses. By controlling the combs, researchers hope to create optical sensors that detect and measure hazardous materials or pollutants, spectroscopy systems for laboratory research, and optical communications systems.

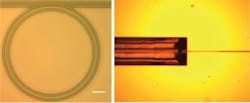

The microring resonator is approximately 80 µm in diameter and fabricated from silicon nitride. Infrared laser light enters the chip through a single optical fiber and is directed by a waveguide into the microring. Nonlinear interaction produces a comb of many frequencies, including the original one.

Andrew Weiner, the Scifres Family Distinguished Professor of Electrical and Computer Engineering at Purdue says, "The microring comb generator may serve as a competing technology to a mode-locked laser, which generates many frequencies and short pulses. One advantage of the microrings is that they can be very small."

Findings are detailed in a research paper appearing online this month in the journal Nature Photonics (Spectral Line-by-Line Pulse Shaping of an On-Chip Microresonator Frequency Comb; Dec. 11, 2011).

Although other researchers have demonstrated the comb-generation technique, the team is the first to process the frequencies using optical arbitrary waveform technology first developed by Purdue researchers led by Weiner. The researchers were able to control the amplitude and phase of each spectral line, learning that there are two types of combs—highly coherent and partially coherent—and opening up new avenues to study the physics of the process.

"In future investigations, the ability to extract the phase of individual comb lines may furnish clues into the physics of the comb-generation process," said doctoral student Fahmida Ferdous. "Future work will include efforts to create devices that have the proper frequency for commercial applications."

The silicon-nitride device was fabricated by a team led by Houxun Miao, a researcher at NIST's Center for Nanoscale Science and Technology and the Maryland Nanocenter at the University of Maryland. Some of the work was performed at the Birck Nanotechnology Center in Purdue's Discovery Park, and experiments demonstrating short-pulse generation were performed in Purdue's School of Electrical and Computer Engineering.

SOURCE: Purdue University Ultrafast Optics and Optical Fiber Communications Laboratory

Subscribe now to Laser Focus World magazine; It’s free!

Follow us on Twitter

About the Author

Conard Holton

Conard Holton has 25 years of science and technology editing and writing experience. He was formerly a staff member and consultant for government agencies such as the New York State Energy Research and Development Authority and the International Atomic Energy Agency, and engineering companies such as Bechtel. He joined Laser Focus World in 1997 as senior editor, becoming editor in chief of WDM Solutions, which he founded in 1999. In 2003 he joined Vision Systems Design as editor in chief, while continuing as contributing editor at Laser Focus World. Conard became editor in chief of Laser Focus World in August 2011, a role in which he served through August 2018. He then served as Editor at Large for Laser Focus World and Co-Chair of the Lasers & Photonics Marketplace Seminar from August 2018 through January 2022. He received his B.A. from the University of Pennsylvania, with additional studies at the Colorado School of Mines and Medill School of Journalism at Northwestern University.