Newly developed AI tool could transform traditional microscopy

Researchers in Sweden have discovered that a new artificial intelligence (AI) tool has the potential to fundamentally change microscopy, thanks to new ways of analyzing images.

Developed by a team at the University of Gothenburg, the AI tool uses neural networks that can learn how to retrieve the exact information sought from an image by looking through huge training data (a large number of images).1 The researchers say this is akin to technologies and applications with which we largely unknowingly and often interact—for example, services such as Spotify, which find and recommend songs and accompanying photos based on music a user has listened to before.

“We have now developed a tool that makes it possible to utilize the incredible potential of deep learning, with focus on images taken with microscopes,” says the study’s lead author Benjamin Midtvedt, a doctoral student in physics at the University of Gothenburg. Traditionally, producing that data has been done manually—this new tool simplifies that process, “so that tens of thousands of images can be generated in an hour instead of a hundred in a month.”

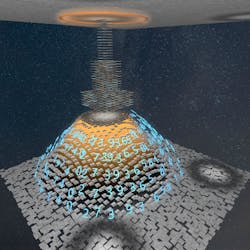

The study focuses specifically on deep learning, which the researchers note that in relation to microscopy, retrieving a large amount of information from data-filled images has been challenging. Deep learning, on the other hand, has proven to be very effective (see figure).

“Regardless of the microscopic challenges,” Midtvedt says, “researchers can now more easily conduct analyses, make new discoveries, implement ideas, and break new ground within their fields.”

Users are able to control the size and material characteristics for very small particles with the new deep learning tool, and also easily count and classify cells. In the study, researchers have seen, in real time, unwanted particles in the data and whether they have all been filtered out.

“This makes it possible to quickly extract more details from microscope images without needing to create a complicated analysis with traditional methods,” Midtvedt says. “In addition, the results are reproducible and customized, and specific information can be retrieved for a specific purpose.”

He adds that as his team has already demonstrated the tool’s ability to filter out unwanted particles in real time, it has garnered attention from industries that need to purify emissions. Other future applications for the new tool could include those in the biomedical realm, such observation of infected cells or mapping cellular defense mechanisms.

REFERENCE

1. B. Midtvedt et al., Appl. Phys. Rev., 8, 011310 (2021); https://doi.org/10.1063/5.0034891.

About the Author

Justine Murphy

Multimedia Director, Digital Infrastructure

Justine Murphy is the multimedia director for Endeavor Business Media's Digital Infrastructure Group. She is a multiple award-winning writer and editor with more 20 years of experience in newspaper publishing as well as public relations, marketing, and communications. For nearly 10 years, she has covered all facets of the optics and photonics industry as an editor, writer, web news anchor, and podcast host for an internationally reaching magazine publishing company. Her work has earned accolades from the New England Press Association as well as the SIIA/Jesse H. Neal Awards. She received a B.A. from the Massachusetts College of Liberal Arts.