Diamond metasurfaces increase damage thresholds in high-power laser systems

Synthetic diamond supermaterials company Element Six (Santa Clara, CA), a member of the De Beers Group of Companies, has developed a new diamond optics product called Diamond PureOptics. Drawing inspiration from the antireflective structure of a moth's eye, Element Six says the all-diamond solution offers improved reliability and even higher power density levels for high-power carbon-dioxide (CO2) and other laser systems.

RELATED ARTICLE: CVD diamond extends Raman laser capabilities

Due to a combination of superlative thermal, mechanical, and optical properties, diamond grown by chemical vapor deposition (CVD) is a new material of choice for windows for high-power, multi-kilowatt CO2 laser systems since its wide transmission window from the ultraviolet all the way to the radio-frequency part of the electromagnetic spectrum combined with the highest hardness and thermal conductivity of any material makes it a stand-out component for robust optics.

As demands increase for faster throughput and new applications emerge such as extreme ultraviolet (EUV) lithography that uses CO2 lasers to generate sub-10 nm radiation, advanced solutions are required to produce more robust optics. To meet the associated application requirements, Element Six says it has pushed diamond synthesis and processing capabilities to new heights.

Diamond optical windows typically include an antireflective (AR) thin-film coating to minimize reflection losses at each surface, associated with the change in refractive index of diamond to air, maximizing laser output power. However, these coatings have mechanical and thermal properties that can be 1,000 times inferior to those of the intrinsic diamond, leading to increased thermal and mechanical failures as optical power densities increase.

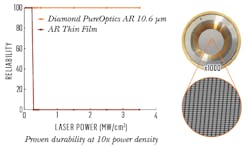

By mimicking the structure of a moth's eye, Element Six has replaced these thin films with a diamond structured surface designed to reduce reflection losses, shifting the reliance of the optics solely onto the outstanding intrinsic properties of diamond. Diamond PureOptics with metasurfaces (MS) has improved reliability and allows even higher power density levels for high power CO2 laser systems. Ideally suited for EUV applications, the all-diamond MS design exhibits significantly higher laser-induced damage threshold (by a factor of 10) than AR coated windows, with equivalent reflectance (less than 0.5%) and transmission (above 99%).

"With the industry trending to even more powerful CO2 laser sources and the high costs associated with system downtime, the need for more durable and reliable anti-reflective laser windows is critical," said Bruce Bolliger, head of sales and marketing at Element Six Technologies. In benchmarked tests, AR-coated windows demonstrated a laser induced damage threshold of approximately 0.25 MW/cm2, but the same laser was unable to damage the MS window at all, even at power densities 10 times higher. Additionally, exchanging AR coatings with MS decreased overall window absorption, helping to keep window operating temperatures low and minimize thermally induced beam distortion.

Element Six's Diamond PureOptics optical windows with anti-reflective MS structures for 10.6 micron wavelengths have been designed, fabricated, field-tested, and are available now for shipment. The company is also developing Diamond PureOptics solutions for other wavelengths.

SOURCE: Element Six; http://www.e6.com

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.