How to choose a laser for microscopy

Fluorescence microscopy is a universal tool throughout the life sciences because of its unique ability to map a wide variety of target biochemicals as well as physical structure (morphology). In many fluorescence-microscopy applications, and particularly confocal laser scanning microscopy (CLSM), the laser is used as the light source because of its unique combination of spatial brightness and monochromaticity (spectral brightness).

The wide variety of available lasers, each defined by multiple technical performance parameters, can make choosing one a daunting decision for the non-laser expert. But this choice often determines the success of experiments. In this article, we review the most critical of these parameters and explain the impact they have on microscope performance.

Wavelength

Wavelength is the most obvious laser parameter, but the choice of optimum wavelength is not always a trivial exercise. The simplest approach is to match the laser wavelength to the peak of the fluorophore excitation spectrum and use a cut-off or bandpass filter to block scattered laser light from reaching the camera or photodetector, which then only detects the Stokes-shifted fluorescence emission.

The laser has a much sharper spectrum (that is, spectral width and slope) than the filter, so it’s often better to work back from the filter. For example, many users often choose to excite a fluorochrome with a laser on the short-wavelength slope of the excitation peak. The reason is that, by moving to a shorter wavelength, the separation between any scattered laser light and the longer wavelength fluorescence is increased, reducing the filtering challenge and increasing signal to noise (image contrast).

Filtering challenges are becoming ever more critical as microscope manufacturers and users move to a wider and wider palette of excitation wavelengths to enable a single microscope system to image multiple fluorophores, in the same experiment or as a shared resource. Today, microscopes are commonly equipped with up to seven different wavelengths.

The need to avoid crosstalk between multiple lasers and detection channels is also one of the drivers behind the growing interest in expanding the wavelength bandwidth of microscope operation into the near-infrared (near-IR) spectral region. Clever techniques that involve anti-Stokes emission enable images to be detected using a single silicon-based camera type—silicon CCD/CMOS quantum efficiency drops off rapidly beyond 800 nm. Laser manufacturers are responding to this need with lasers at wavelengths including 808 nm and even 980 nm.

Power

Power is the other obvious laser output parameter, where image intensity is approximately proportional to laser power. Laser-excited fluorescence is an efficient process in most fluorophores, with quantum efficiency often close to unity. Conversely, the confocal microscope is an optically inefficient system, where the confocal pinhole blocks as much as 99% of fluorescence collected by the objective, sacrificing image intensity for three-dimensional resolution.

But choosing the maximum laser power is not always the best option, since photodamage and scattered light both increase with laser power, as does laser cost. As a general rule, about 1 to 10 mW of power at the sample is usually a good power level for many confocal applications, which means a few tens of milliwatts at the laser output, based on the efficiency of typical microscope illumination and scanning optics.

Some applications need more power. For instance, the newer scanning-disk microscopes support faster frame rates by imaging multiple focal spots in the sample simultaneously. Here, higher power is typically required to provide the requisite intensity (and hence speed) at each focal spot.

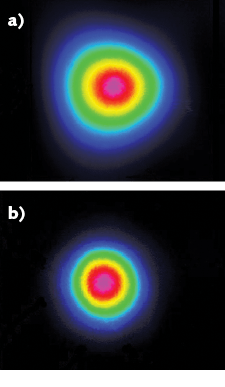

Superresolution techniques such as photoactivated localization microscopy (PALM) and stimulated emission-depletion (STED) also need higher power, since these techniques depend on switching fluorophores on and off via bleaching or saturation (see Fig. 1). Until recently, this meant using powers in the watts range—but this represents power and cost overkill. The optimum power is actually a few hundred milliwatts, and laser manufacturers now support these applications with a growing number of laser wavelengths available in the 250–500 mW power range.

Beam quality

Beam mode quality directly affects focused spot size, which in turn determines system optical efficiency. This is because a confocal microscope works by focusing the laser to a small spot or spots in the sample plane and imaging fluorescence from this spot through a confocal aperture. Any light that is focused outside the target spot is not only wasted power, but can also increase background noise, thus reducing overall image contrast.

Multimode lasers can be used with a confocal microscope, but usually in conjunction with optics to homogenize and spatially filter the light, which increases complexity and lowers efficiency. Thus, while multimode lasers with lower-quality beams are often easier to make and so are usually available at lower cost, they usually represent false economy.

Simply stated, a CLSM works best with a TEM00 laser. In terms of specifications, this translates into an output specified at >80% TEM00 content or M2 <1.2.

Laser noise is another important factor impacting confocal image quality. The intensity noise must be low across a wide bandwidth (for example, 20 Hz to 20 kHz) to minimize image noise. This includes both the average, or root-mean-squared (RMS) noise and the peak-to-peak noise. Beam pointing shifts as a function of temperature can also translate into intensity noise and resolution loss—we recommend <5 µrad/°C.

Modulation

Scanned images require some modulation capability: at a minimum, the ability to turn the laser off during fly-back is required. Modulation can include both digital and analog specifications. Digital is a simple on/off switching, whereas analog varies the power according to an analog input signal.

In terms of speed, laser diodes provide the fastest modulation, with megahertz digital and analog switching rates, but the analog dynamic range is limited to just over 100:1. Optically pumped semiconductor lasers (OPSLs) offer slower modulation (max values: 50 kHz digital, 100 kHz analog) with similar (50:1) dynamic range, and DPSS lasers do not support modulation at all. Thus, depending on the laser type, direct modulation is often possible. However, direct modulation is often not a critical factor since most microscopes also incorporate either an acousto-optic modulator (AOM) or acousto-optic tunable filter (AOTF) to enable modulation.

Fiber delivery

Confocal microscopes are set up to receive laser light via a single-mode fiber connector. The FC/APC (ferrule connector/angled physical contact) standard is most commonly used and represents about 80% of the market. Some of the newer formats—for example, spinning-disk microscopes—have moved to using the FC/PC8 connector. Lasers are available with free-space output beams, pigtailed to bare fiber, or pigtailed to fiber terminating in a connector.

Coupling a laser into a single-mode fiber is extremely challenging, requiring adjustments in six degrees of freedom to control the sensitive alignment of high numerical aperture (NA) optics. This alignment can take hours to optimize and, for virtually all microscope users, it is simply not worth the effort. It makes more sense to purchase a laser already equipped with the correct fiber-connector termination for the microscope or beam combiner.

A note of caution about fiber-coupled lasers: in first-generation products, particularly at shorter wavelengths and high power, the transmitted power can degrade by as much as several percent in just a few hundred hours, resulting in a useful life as short as 1000 hours. The main culprit is fiber facet damage (photodeposition) because of the high-intensity focus needed for single-mode fiber coupling. (A less common culprit is photodamage to the fiber itself). For this reason, laser manufacturers have implemented proprietary schemes, such as Coherent’s “Extended Life Interface,” to lower the power density at the fiber facet, but without losing the single-mode properties of the fiber. These schemes extend the typical lifetime of the laser/fiber unit to 10,000 hours or more.

Compatibility across multiple lasers

With up to seven lasers attached to a single microscope input, another issue is laser commonality. For both the microscope manufacturer and the end user, the integration of multiple lasers and upgrades with new lasers are both much simpler if the lasers all have the same form, fit, and function. This means the same power supply, the same thermal management requirements, the same electronic interface, the same beam position, diameter, divergence, azimuth, and so on.

Laser manufacturers support this need for multi-laser commonality by packaging all the lasers for life sciences applications in the same power-delimited format, irrespective of the internal technology (see “A note about laser technology”). In addition, these lasers typically now incorporate smart plug-and-play technology enabling simple exchange of lasers to upgrade the power, add a new wavelength, or replace a laser after its useful lifetime. The OBIS family of lasers from Coherent is an example of this common smart platform concept.

This common platform concept has been recently extended to physical integration, where several lasers are mounted in a single housing, eliminating the need for multiple identical power supplies and simplifying the overall system footprint. Coherent’s version of this is called Laserbox with the option of a single touchscreen controller to operate all the lasers.

Beam combining

The final step is interfacing all the lasers into a single input fiber connector (FC/APC or FC/PC8) at the microscope. Traditionally, this entailed collimating the beam from each laser and successively combining them using multiple dichroic beamsplitters. The combined beam then had to be efficiently coupled into a single-mode fiber using a lens whose optical properties inherently vary with wavelength. Thankfully, there are off-the-shelf integrated modules to seamlessly combine the lasers with no user alignment or adjustment required. This takes the plug-and-play functionality of the smart modules to its natural conclusion, with fiber-connected lasers added or swapped in seconds instead of hours.

The first of these beam-combining modules was the Galaxy from Coherent (see Fig. 2), which has FC input connectors for up to eight user-selected wavelengths using patented technology. This uses a minimum number of internal refractive optics to couple the beams into a single pre-aligned output fiber. This single-mode polarization-preserving fiber terminates in a user-specified FC/APC or FC/PC8 to connect directly with all popular confocal microscopes.Laser advances have enabled a new generation of fluorescence microscopy tools that offer greater functionality, simplified operation, and lower cost. However, this very success has crowded the market with products, sometimes making it difficult to choose the optimum solution for a given application. Understanding how a few key laser parameters affect microscope performance can simplify this choice and lead to improved results.

REFERENCE

1. J. Y. Hsiao, L. M. Goins, N. A. Petek, and R. D. Mullins, Curr. Biol., 1–10 (2015).

A note about laser technology

Historically, lasers were specified by their technology, wavelength, and power rating. Today, however, microscope builders and users alike only care about output beam properties, not the underlying laser technology used to produce it. This paradigm shift began when laser manufacturers developed common platforms irrespective of technology. For example, Coherent packages two complementary semiconductor technologies—laser diodes and optically pumped semiconductor lasers (OPSLs)—in the same plug-and-play format. The reason is that diodes excel for efficiency and higher modulation speeds at short (≤488 nm) wavelengths, as well as at red/near-IR wavelengths (≥640 nm). Conversely, OPSL technology provides wavelengths across the middle of the visible spectrum and into the ultraviolet, where diodes are not yet practical. And OPSL technology is also power-scalable, enabling superresolution applications with power in the hundreds of milliwatts.About the Author

Dan Callen

Product Line Manager, Direct-diode Laser Systems at Coherent

Dan Callen is Product Line Manager for Direct-diode Laser Systems at Coherent (Santa Clara, CA).

Matthias Schulze

Director of Marketing, OEM Components and Instrumentation at Coherent

Matthias Schulze is Director of Marketing, OEM Components and Instrumentation at Coherent (Santa Clara, CA).

![FIGURE 1. These total internal reflection fluorescence microscopy images were obtained using two excitation lasers combined in the Coherent Galaxy laser combiner; as part of research on the binding of actin filaments, the red signal is from Cy5-labeled Tm1A (protein) fluorescence excited at 640 nm, and the green signal is due to Alexa488 labeled actin excited at 488 nm. [1] FIGURE 1. These total internal reflection fluorescence microscopy images were obtained using two excitation lasers combined in the Coherent Galaxy laser combiner; as part of research on the binding of actin filaments, the red signal is from Cy5-labeled Tm1A (protein) fluorescence excited at 640 nm, and the green signal is due to Alexa488 labeled actin excited at 488 nm. [1]](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2018/07/content_dam_lfw_print_articles_2018_06_1806lfw_cal_f1.png?auto=format,compress&fit=fill&fill=blur&q=45?w=250&width=250)