Sapphire optical fiber reduces background noise in Raman imaging probe

Optical-fiber-based Raman imaging probes are traditionally made with silica optical fibers. Unfortunately, silica has strong broadband background noise at low wavenumbers of less than 500 to 1700 cm-1 (which are characteristic of many biological proteins, fatty acids, and hydrogen-bonded chemicals, as well as oxidizing metals) and obscures the weak Raman signal received from a material under test. This is why current Raman imaging fiber probes have two silica fibers—one to bring the light to the sample and another to collect the light and filter it through additional optical elements in the probe. This introduces a limitation on the miniaturization of Raman imaging probes.

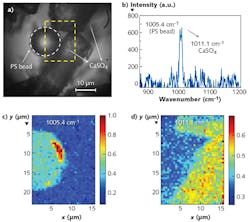

To address these challenges, researchers at EPFL (Lausanne, Switzerland) and Baidu Shenzhen R&D Center (Shenzhen, China) have constructed an improved small-diameter (60 µm) Raman imaging probe using multimode sapphire optical fiber, taking advantage of its inherent low fluorescence, narrow Raman peaks, high temperature and corrosion resistance, and large numerical aperture (NA). The probe successfully images polystyrene beads, carbon nanotubes, and calcium-sulfate (CaSO4) agglomerations with a spatial resolution of 1 µm in a 30 µm field of view. The sapphire fiber is used for both excitation and collection of the Raman signal without any focusing optics. In one measurement, the closely spaced Raman spectral peaks of a polystyrene bead (1005.4 cm-1) and a CaSO4 agglomeration (1011.1 cm-1) were easily distinguished. Reference: S. Deng et al., Opt. Express,27, 2, 1090–1098 (2019).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.