Fiber Bragg Gratings: Dissolvable optical fiber with FBGs aims at inside-the-body medical sensing

Researchers at the Institute of Electronic Structure and Laser (IESL) of the Foundation of Research and Technology – Hellas (FORTH; Heraklion, Greece), in collaboration with scientists from the Politecnico di Torino and Istituto Superiore Mario Boella (both in Torino, Italy), have created the first fiber Bragg gratings (FBGs) inside a bioresorbable optical fiber.1

FBGs are widely used in optical fibers for sensing of temperature, strain, and other parameters. Under development, bioresorbable fibers, which potentially can be used for medical sensing, are safe inside the body because, if they break, the shards dissolve and are absorbed by the body. This first-time combination of these sensors and fibers could be used to sense pressure at joints or act as small probes that can safely reach and assess the heart and other delicate organs. Laser-based techniques for removing tumors could also be improved, which could simultaneously deliver a surgical laser beam and provide the accurate real-time temperature sensing necessary to monitor the laser-ablation process.

“Our approach could potentially be used to create various types of interconnected structures in or on bioresorbable optical fibers, allowing a wide range of sensing and biochemical analysis techniques to be performed inside the body,” says Maria Konstantaki, a member of the FORTH research team.

To create optical FBGs that could be safely used in the body, the researchers developed a type of glass made of phosphorous oxide combined with oxides of calcium, magnesium, sodium, and silicon. “This glass combines excellent optical properties with biocompatibility and water solubility, thus providing a reliable platform from which to make optical fibers that dissolve in water or biological fluids,” says Daniel Milanese from Politecnico di Torino. “The properties of the optical fibers can be tuned by properly changing the glass composition.”

Tilted or nontilted FBGs

The gratings are created by patterning with a phase mask with a period of 1064.7 nm and using light from a 193 nm high-spatial-coherence excimer laser emitting pulses of 10 ns duration, creating an energy density up to 108 mJ/cm2. Both tilted or nontilted FBGs were fabricated.

Tilted gratings, which allow some of the reflected light to escape from the fiber core and enter into the surrounding cladding, are often used for sensing because changes on the fiber cylindrical surface modify the back-reflected light in a way that can be monitored. The researchers created FBGs with both 1° and 2° tilts and found that the 1° tilt produced a good signal, while the 2° tilt returned no measurable signal.

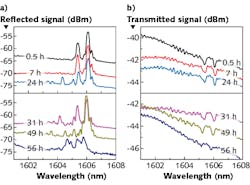

After confirming that the patterns created by the inscription process operated as a FBG, the researchers immersed fibers with and without FBGs into a phosphate-buffered saline (PBS) solution simulating the pH and temperature conditions of the human body for up to 56 hours (see figure). They found that the glass that had been etched with the UV laser light dissolved faster than unexposed glass.

The researchers are now performing experiments to better understand how the fiber composition and UV laser irradiation conditions affect the speed at which the FBG dissolves. This information could be used to create FBGs that dissolve within a specific time period for in vivo applications such as deep-tissue photodynamic therapy. Before being used in people, the dissolving and sensing properties of the FBGs will need to be studied in animals.

REFERENCE

1. D. Pugliese et al., Opt. Lett. (2018); doi:10.1364/ol.43.000671.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.