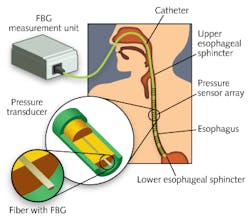

Transport of food through the esophageal tract is a highly coordinated neuromuscular event, and dysfunction of the pressure mechanisms and sphincter muscles causes acid reflux (heartburn) and other diseases. Analysis of esophageal pressure distribution—esophageal manometry—is now being assisted by draw-tower fiber Bragg gratings (FBGs) incorporated into an endoscopic pressure sensor distributed along the esophagus.

An endoscopic FBG-based catheter, developed by the Institute of Photonic Technology Jena (IPHT; Jena, Germany) and Technische Universität Chemnitz (Chemnitz, Germany), has a soft, single-layer nominal 3-to-5-mm-diameter coating that transfers esophageal pressure to an 80-to-125-μm-diameter cerium- or germanium-doped optical fiber at its core. Fiber pressure deformation translates to a change in refractive index (and corresponding changes in the optical grating period) of 30 FBGs spaced roughly 10 mm apart. The FBGs are fabricated continuously on a draw tower using an excimer laser (248 nm) operating at 150 mJ/pulse that is split into two beams that superimpose and form standing waves on the fiber to create permanent, periodic index modulations within the fiber core. A superluminescent light-emitting diode interrogation system transmits 800–860 nm light to the endoscope; the signals reflected by the gratings are analyzed with a CCD array at a 1 kHz sampling frequency to resolve the 20 s travel time of peristaltic waves and corresponding pressure values distributed along the esophagus. Contact Martin Becker at [email protected].

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.