INTERFEROMETRY: Frequency-comb interferometer measures absolute distance

Modifications to a “massively parallel spectroscopy” technique have led researchers to a new means of measuring absolute distance with extraordinary precision.

A team from the Dutch Metrology Institute and the Delft University of Technology (both in Delft, the Netherlands) demonstrated the idea, showing distance precision within a thirtieth of a wavelength over a 15 cm distance—but they say the technique could be applied over thousands of kilometers.

The idea of using light itself as a measuring device goes back to Albert Michelson, the pioneering physicist who refined the measured value of the speed of light in the late 19th century.

Arguably the biggest jump in metrology to occur since those days has been the discovery of the frequency comb, which is associated with ultrafast pulses from modelocked lasers. Recent years have seen a proliferation in both spectroscopy and metrology applications of the frequency-comb technique.

In 2007, collaborators at the National Institute of Standards and Technology (NIST; Boulder, CO) made use of a pair of frequency combs to do massively parallel spectroscopy, using the wavelengths of the constituent teeth of the comb to carry out measurements with each tooth independently.1

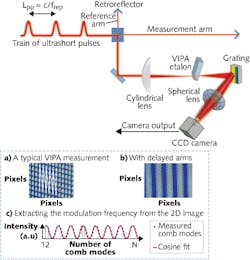

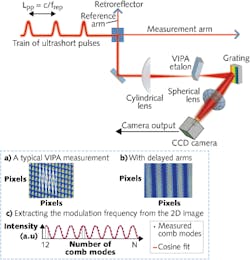

The heart of that measurement was what is known as a virtually imaged phase array (VIPA), which was initially developed for unraveling wavelength-division-mulitplexed (WDM) signals. Its function is similar to that of a Fabry-Perot etalon but designed to offer enhanced angular dispersion, resulting in a far wider spread of output wavelengths than gratings can provide.

Light is focused by a cylindrical lens through the bulk of the VIPA onto its back surface, after which it makes multiple reflections off highly reflective coatings that cover much of its area.

The angularly dispersed output from a VIPA can then be spread in the orthogonal direction with a standard grating, revealing a 2D array of sources, which if properly resolved represent the individual modes: the teeth of the comb.

VIPA for interferometry

But it took the team from Delft to make use of the approach and suggest a revolutionary distance measurement—with a nod to Michelson—by incorporating it into a Michelson interferometer.

Their Ti:sapphire oscillator was frequency-stabilized to a cesium atomic clock to provide an absolute time reference for pulses passing through the interferometer. But further optimization was needed, notes Steven van den Berg of the Dutch Metrology Institute.

“It’s tricky because the papers we read about this application of VIPAs just managed to split a comb into 3 GHz, and we wanted to split it into 1 GHz,” he says. “The question before we started was can we manage to get this high resolution? It’s essential that you see individual dots, because then you can assign a number or frequency to each—it’s important that you can ‘count the dots.’”

The team optimized the coatings on their improved VIPA, increasing its path length and spreading out the frequencies even further. The resulting spectrometer resolved about 9000 modes using 40 fs pulses, with the full set captured in single images on a CCD. The setup is functionally equivalent to an interferometric measurement using 9000 individual lasers.

The frequency scale on the image is calibrated using the output of an optical parametric oscillator along the same path. The relative uncertainty in the frequency measurement is about 10-12, which is far better than previous spectral interferometry techniques.

As the distance in the measurement arm of the Michelson interferometer is varied, the resulting interferograms can be analyzed; the phase change as a function of optical frequency yields an absolute distance measurement.

A comparison test with a helium-neon laser showed a measurement accuracy of about a thirtieth of a wavelength.2 The technique, the authors say, provides the precision of interferometry while maintaining a large ambiguity range, which will be important for eventual applications.

“We demonstrated the principle and imaged a relatively short distance, but it would be interesting to see how far you can get,” says van den Berg.

The range of the measurement is only limited by the bandwidth of the comb, meaning measurements up to thousands of kilometers should be possible—a useful range for future formation-flying satellites that may need to maintain stabilized distances from one another.

Another use of the device would be to measure the refractive index of materials by measuring both the physical and optical length simultaneously, says van den Berg.

REFERENCES

1. S.A. Diddams et al., Nature, 445, 627 (2007).

2. S.A. van den Berg et al., Phys. Rev. Lett. (in press).