Optical Coherence Tomography: Novel design makes OCT more accessible

Optical coherence tomography (OCT) has been unable to realize its full potential. The noninvasive imaging technique quickly became a mainstay in ophthalmology because it allows detection of eye diseases such as diabetic retinopathy and macular degeneration before the patient experiences symptoms. But existing devices range in price from $35,000 to $150,000, keeping OCT beyond the reach of about half of the optometry practices that provide most eye-health services in the U.S. Equipment cost has also gated access for many academic, scientific, and medical research facilities, meaning that OCT-enabled discovery is stymied.

Leveraging resources to lower the bar

OCT was developed at the Massachusetts Institute of Technology (MIT; Cambridge, MA), which is where Adam Wax learned it. Now professor of biomedical engineering at Duke University (Durham, NC), Wax developed a novel OCT system design in 2014. His approach uses relatively inexpensive components, and thus enables construction of an instrument for less than $10,000.

Key to making the system low in cost is a spectrometer that incorporates several inexpensive, high-quality components designed for application in other industries. Using a loop design for the light path keeps the spectrometer compact and easy to align. An economical off-axis parabolic reflector, which requires no high-tolerance mechanical components to mount, collimates the light.

The scanner also makes creative use of components, including a liquid lens designed for the high-volume cell phone market that allows electronic control for beam focus and steering.

Finally, the sensor, which is widely used for such applications as bar-code reading and fingerprint scanning, also does not require tightly controlled mechanical tolerances. Instead of using a standard line-scan array costing several thousand dollars, and with pixels about 5 μm high, the design uses an array costing only a few hundred dollars, with pixels 100–200 μm in height. This means that alignment requires little effort and can be easily maintained, which holds down manufacturing and assembly costs.

With assistance from Duke, Wax patented his low-cost, high-performance design, and began commercialization efforts.

Research and clinical versions

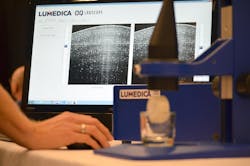

At SPIE Photonics West 2017 (January 28 - February 2; San Francisco, CA), Wax's newest company, Lumedica (Durham, NC), demoed the research version of its prototype, OQ LabScope, which boasts not only a low price, but also compact size (13 × 7.5 × 6 in. and 6 lbs). It also promises robust capability—Lumedica CTO Bill Brown asserts that the system's image quality "is on par with machines costing $40,000 more" (see figure). The system produces 512 × 512 pixel images, A- and B-scan rates of 8800 lines and 12 images/s, respectively, and scan range of 7 mm2. Its output power is 750 μW, depth resolution is 5 μm in tissue, and transverse resolution is 15 μm. With a center wavelength of 840 nm, its sensitivity (optical signal-to-noise ratio) is 100 dB.

"The potential uses for OCT are unlimited, but until these systems get into the hands of more innovators, that potential remains untapped," Wax says.

In addition to demonstrating OQ LabScope at the BiOS Expo, Lumedica presented its technology at SPIE's Startup Challenge, where judges awarded it third prize.

Wax's presentation showed the clinical version of the system with an iPhone, which he said was significant for multiple reasons. "This is a mobile device," he stated—the small form factor allows easy field operation, and transport among clinics.

It operates not through a computer, but by Bluetooth through a phone or tablet, making it easy to operate. Wax's team worked with Duke MBA students to identify different customer profiles, including Millennial optometrists familiar with OCT, but deterred by the cost of traditional systems, and experimentalists with installed patient bases who want to add services to their practices—and validate the design with them.

With an ultimate goal of giving more patients access to the one test that can save their vision and improve their quality of life, Wax hopes his innovation will enable more healthcare providers to conduct OCT imaging. In the meantime, he plans to seek FDA approval for the clinical device and get the research version into more labs to facilitate scientific discovery. And in case you were wondering, he hints at future developments, saying, "I've got several different low-cost biomedical imaging technologies in the pipeline."

About the Author

Barbara Gefvert

Editor-in-Chief, BioOptics World (2008-2020)

Barbara G. Gefvert has been a science and technology editor and writer since 1987, and served as editor in chief on multiple publications, including Sensors magazine for nearly a decade.