Gemologists, as well as reputable jewelers, have an interest in identifying authentic gems so as to separate them from counterfeits. In the case of diamonds, synthetic diamonds are a legitimate product as long as they are identified and sold as synthetics. However, certain producers of diamonds have been known to try to pass off synthetic diamonds as their much more expensive natural counterparts. In addition, the color of diamonds can be modified by certain treatments so as to imitate expensive naturally colored diamonds. Finally, other materials such as synthetic spinel can more crudely imitate diamonds.

Existing techniques to separate real from fake include older approaches such as measuring a sample’s index of refraction, birefringence, and specific gravity; newer approaches, often used in combination, include forms of spectroscopy including Fourier-transform infrared (FTIR), Raman, UV-visible absorption, photoluminescence, and x-ray fluorescence. However, these are involved and time-consuming techniques that are not suitable for rapid inspection, especially of the 0.2 carat and smaller diamonds that make up by far the largest number of diamonds sold for jewelry.

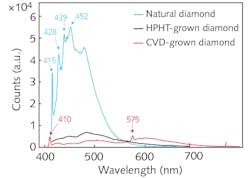

Now, Tsung-Han Tsai and Ulrika F. S. D’Haenens-Johansson of the Gemological Institute of America (New York, NY) have developed a quick way to separate colorless and near-colorless natural diamonds from synthetic diamonds and diamond-imitating materials; as a bonus, the technique allows identification of some other gemstone materials including corundum, spinel, beryl, garnet, and topaz. Their approach, designed for speed and simplicity, is based on UV fluorescence spectroscopy with a 385-nm-emitting LED as a light source, filters to separate the fluorescence from the LED light, and a spectrometer.1 (The 385 nm wavelength was selected because it excites the nitrogen N3 defects that are prevalent in natural diamonds.)

Handheld fiber probe

In the device, a 390 nm shortpass filter and optics remove any visible light from the LED and focus the resulting light into six optical fibers, leading to a small, handheld probe that is held to the gemstone under test. A seventh optical fiber transmits the fluorescence from the gemstone back to the spectrometer, where it is filtered by a 409 nm longpass filter before entering the spectrometer.

In tests (see figure), the device easily and rapidly discriminated between natural diamonds, which produced N3 fluorescence; synthetic diamonds grown using a high-pressure, high-temperature (HPHT) technique, and synthetic diamonds grown via chemical vapor deposition (CVD). In addition, fake diamond materials such as synthetic spinel, zircon, gadolinium gallium garnet, synthetic sapphire, and yttrium aluminum garnet (YAG) were identified via their very distinct fluorescence spectra. In a third test, natural pink diamonds, treated pink diamonds, and pink diamonds grown using either HPHT or CVD could all be uniquely identified. Successful tests were also done on gemstones mounted in a pendant, Identifying a single HPHT-grown diamond among 19 natural diamonds.

The researchers next plan to work on widening the variety of colored diamonds and other gemstones that can be identified—and to keep up with the ever-evolving techniques being developed to fabricate synthetic diamonds that are more and more indistinguishable from natural diamonds.

REFERENCE

1. T.-H. Tsai and U. F. S. D’Haenens-Johansson, Appl. Opt. (2021); https://doi.org/10.1364/ao.419885.