X-ray Imaging: Noninvasive colonoscopy comes without the yuck factor

Colorectal cancer is the second deadliest cancer in the West, and yet with early detection it is typically preventable or treatable. Optical colonoscopy, today's standard screening tool, offers great sensitivity and specificity, but if you've ever had one, you know why people tend to avoid it: Not only does the invasive procedure carry a level of risk, but preparation is demanding—and uncomfortable.

The multitudes will be grateful for a technology that aims to increase compliance and throughput by overcoming numerous limitations of the conventional method. Check-Cap's (Mount Carmel, Israel) C-Scan imaging capsule not only provides noninvasive screening, but the device uses advanced x-ray technology, which, unlike optics, can see through intestinal content, rendering unnecessary the dreaded bowel prep. And the new technology produces comparable screening accuracy.

The capsule images the colon's lining using significantly less radiation than procedures that operate outside of the body. In addition, the ultralow-dose x-ray transmission occurs only while the capsule is in motion. As a result, imaging the entire colon requires no more radiation than does a chest-x-ray—and most imaging procedures currently used.

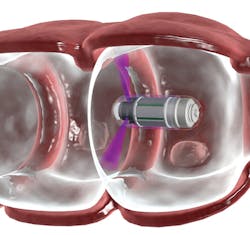

The C-Scan's analysis of distances (measured by transmitting x-rays to the intestinal wall and back) creates 360° angular scans of the colon's internal surface, enabling the detection of clinically significant polyps with a high degree of sensitivity (see figure).

According to Check-Cap's CEO Bill Densel, the capsule's photon detectors require high voltage for proper functioning. A gallium nitride component from Efficient Power Conversion (El Segundo, CA) "allowed us to develop a power generator for the detectors that provided the necessary voltage and was of extremely small size to fit in the capsule."

System operation

Once prescribed, the patient swallows the capsule in the doctor's office along with a small amount of a radio-opaque contrast agent (such as barium sulfate or iodine) to enhance the contrast of the colon surface. The patient drinks the same small amount of contrast agent with meals during the remainder of the screening. The disposable capsule, which travels through the digestive system, is naturally excreted within 24 to 48 hours. When the device enters the colon, it makes its 360° angular scans and broadcasts the image data to an external receiver worn on the patient's body. The receiver stores the information for offline analysis, and indicates when the capsule has been excreted.

When the data is collected from the receiver, a physician can analyze it using data viewer software, which produces 2D and 3D visualizations. The physician can detect cancerous and precancerous polyps, which protrude inward into the colon, by identifying irregularities in the image topography. The analysis can be done at any location and any time, in less time than is required to perform an optical colonoscopy. The physician will then advise the patient on next steps, as appropriate.

A few segments of the population, including those unable to swallow capsules, those with narrow colons, and those who are symptomatic, may not be able to use the device. Otherwise, though, the technology promises to allow doctors to spend less time on screenings and more time with patients who need therapeutic treatment.

Check-Cap began enrolling patients in a multicenter study in January 2017. The prospective trial, designed to demonstrate the safety and clinical performance of C-Scan, will evaluate polyp detection as compared to colonoscopy. Check-Cap expects to submit for a CE Mark in the first half of 2017. Densel expects 2017 to be a pivotal year for the firm. "In addition to submitting for a CE Mark," he says, "we plan to initiate a pilot trial in the U.S. in the second half of this year. Recently, we held our first presubmission meeting with the U.S. Food and Drug Administration and were encouraged by our initial discussions with the Agency," he said.

About the Author

Barbara Gefvert

Editor-in-Chief, BioOptics World (2008-2020)

Barbara G. Gefvert has been a science and technology editor and writer since 1987, and served as editor in chief on multiple publications, including Sensors magazine for nearly a decade.