Off-spindle-axis spiral ground molds produce sub-micron-accurate aspheric microlens arrays

While direct grinding and polishing methods can be used to manufacture aspheric lenses and microlens arrays with form accuracy of around 100 nm and nanometer-scale surface roughness, the process can be time-consuming and expensive, with volumes limited to small batches. Recognizing that molded optics can be manufactured in larger volumes and at lower costs, scientists at the Centre of Micro/Nano Manufacturing Technology (MNMT) at Tianjin University (Tianjin, China) have developed an off-spindle-axis (OSA) spiral grinding method that can be used to fabricate tungsten carbide molds to produce glass aspheric microlenses and microlens arrays.

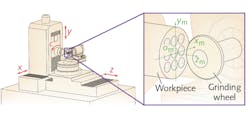

To grind an aspheric mold array with multiple aspheric lenslets, OSA spiral grinding uses a four-axis ultraprecision machine with x, y, and z translational stages and a rotational c axis. A v-type rounded-off grinding wheel with its rotation axis parallel to the x axis follows a mathematically determined spiral path to define the rotationally symmetric aspheric surface of the individual lenslets. To maximize the form accuracy of a single lenslet, the wheel path is finessed by on-machine profile error compensation analysis and subsequent compensation grinding steps. Aspheric lens arrays with four lenslets (of roughly 3 mm diameter) fabricated using the resultant carbide mold blank had form accuracy of <250 nm and surface roughness of around 10 nm. Reference: G. Yan et al., Opt. Express, 27, 8, 10873–10899 (2019).About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.