Pulse stretcher for ArF immersion lithography reduces speckle

NATALLIA KARLITSKAYA and RAJASEKHAR M. RAO

As chipmakers continue extending the use of 193 nm argon fluoride (ArF) immersion lithography to the 7 nm node and below, variables that were previously inconsequential to the successful patterning of wafers have become more impactful, requiring solutions to minimize their negative effects. In particular, excimer-laser light sources used to illuminate mask patterns and project these features onto photoresist-coated wafers are now showing the potential impact of a self-interference phenomenon called speckle. Speckle leads to local illumination nonuniformity, which can in turn result in a nonuniform exposure of photoresist and result in poorer pattern fidelity.

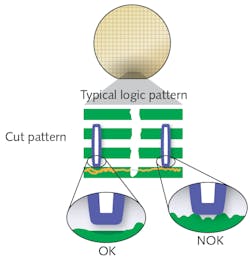

This effect can be observed in the form of printed features that have rough edges (see Fig. 1), commonly characterized as line-width roughness (LWR) or line-edge roughness (LER). While LWR can have several contributors, one of these is laser speckle, specifically speckle contrast, leading to local illumination intensity variation during photoresist exposure. A given pattern with a high degree of LWR can lead to poor registration relative to the previous or next pattern layer in the wafer-process sequence, resulting in electrical failure of the resultant semiconductor device, either via a short or an open circuit.

Excimer light sources for lithography

Cymer, an ASML company, develops lithography light sources used by chipmakers worldwide to pattern advanced semiconductor chips. Cymer has introduced a number of technological advances in recent years on its flagship XLR excimer light source, including higher power with flexibility to address a wide range (60–120 W), improved energy stability, improved bandwidth, and wavelength stability.

In June 2020, Cymer introduced its seventh-generation argon fluoride (ArF) laser, XLR 960ix; this laser type is developed and integrated to the newest ASML NXT:2050i scanner exposure system. XLR 960ix includes technology to decrease edge-placement error (EPE) via reduction of speckle contrast. This is achieved by increasing the laser pulse duration using a new laser optical pulse stretcher (OPuS), depicted on top of the laser in Figure 2. The XLR 960ix laser also features the optional capability for Multi-Focal Imaging (MFI). It targets depth of focus (DoF) improvements for applications with “tall” structures on the wafer. This will enable overall throughput improvements by reducing need for double exposure for “tall” structures.EPE reduction, CDU improvement

One on-wafer improvement that XLR 960ix brings is edge placement error (EPE) reduction. Edge placement error is the difference between the intended and the printed edge location of any feature. Critical dimension uniformity (CDU) relates to the accuracy with which a width of a feature can be reproduced in resist. Both EPE and CDU become more important as feature sizes shrink.

Edge placement error variation budget is dominated by local CD errors, overlay, and optical proximity correction residuals. Local CD errors are associated with line-width roughness that depends on resist properties, local mask errors, and photon stochastics.

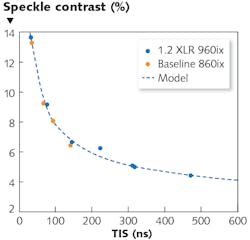

Photon stochastics is associated with the coherence of the laser’s light, which—through interference—leads to random local dose variations, or speckle. Reduction of EPE is possible by reducing the speckle contrast (SC).

Speckle contrast

The speckle is an intensity pattern of dark and bright spots due to coherent light interference. Speckle contrast is the standard deviation of the intensity variation divided by the mean intensity; it is a measure of intensity variation and therefore represents dose variation.

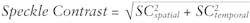

The speckle contrast of a multimode laser is characterized by contribution from both spatial coherence (SCspatial) and temporal coherence (SCtemporal):

The speckle contrast can be rewritten in the following:

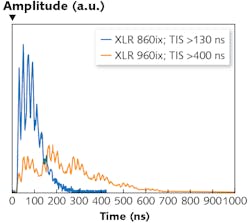

where λ is the source wavelength and c is the speed of light. Decreasing the speckle contrast is possible by increasing the etendue, which is the product of the beam size Abeam and the source divergence Ωdivergence. However, increasing the etendue requires a significant redesign of the laser main components, which is a quite-complex effort. On the other hand, it is possible to increase the spectral laser bandwidth (BW), but this will negatively impact the image contrast. In contrast, increasing the time-integral square (TIS) pulse length is an easier approach to achieving speckle contrast reduction.

Pulse stretching technology

Increasing the TIS is achieved using the new optical pulse stretcher, OPuS. A simplified schematic of the pulse-stretching principle is shown in Figure 3: the beam enters OPuS from the first stage, part of the beam splits off, and then reflects via the series of mirrors in the second, third, and fourth stages. This creates differences in light path that delay them and, therefore, increase the pulse length. In the end, the same amount of energy is stretched over several recombined copies.Natallia Karlitskaya is product marketing manager and Rajasekhar M. Rao is principal systems engineer, both at Cymer, an ASML company, San Diego, CA; e-mails: [email protected] and [email protected]; cymer.com.