Advanced Optics: Photonic crystal adds functionality to healable hydrogel

A new photonic-crystal tissue scaffold could be a valuable tool for investigating treatments for liver cancer, the fastest-increasing cause of cancer death in the U.S. The technology is being developed by Professor Yuanjin Zhao’s group at Southeast University (Nanjing, China). As in all photonic crystals, the color of the material is dictated by the structure. The voids in the structure are filled by a gel that serves as a scaffold for hepatocyte (liver cell) growth. By color-coding sections of the gel corresponding to different drug applications, researchers can quantify the response of cancerous liver cells. The researchers extended their previous work by developing a “healable” gel, one that can repair cracking or other damage (see figure).

A scaffold of silica

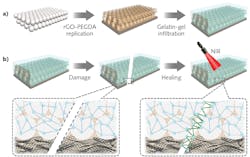

To fabricate the photonic-crystal scaffold, the team starts with silica nanoparticles of a given size. When deposited on a slide, the round particles self-assemble into a regular hexagonal close-packed structure. The team formulated a pregel solution of graphene oxide (GO) and poly(ethylene glycol) diacrylate (PEGDA)—this fills the gaps around the close-packed silica nanoparticles before being UV-cured. When the silica nanoparticles are etched away, the remaining structure is the common inverse-opal scaffold, a photonic crystal with well-defined forbidden bands, leading to reflection at a narrow range of visible wavelengths. The color is defined by the spacing between layers, which is in turn defined by the size of the silica nanoparticles.

With the photonic crystal formed, the team then fills the inverse-opal structure with a gelatin/agar mixture. The melting point and the viscosity of the filler medium can be tuned by modifying the ration between gelatin and agar. The goal is to create a medium that is fluid enough to completely fill the gaps while having a “convenient” melting point. Convenience is defined here as being high enough so the medium is solid at physiological temperatures, and low enough to melt while living cells are still viable.

If the hydrogel is damaged, it can be healed by heating above the melting point, where the medium reflows to heal any discontinuities, and then cooled to resolidify in the photonic-crystal scaffold. The GO in the photonic-crystal matrix absorbs near-infrared (near-IR) light efficiently, and is also a good thermal conductor. So the structure can be healed by shining near-IR until the scaffold reaches the gel melting point, then cutting off the near-IR and letting the structure cool.

Disease treatment research

Zhuoyue Chen, a researcher in Professor Zhao’s lab, says the composed gel was designed for liver-on-a-chip or liver-tissue engineering in vitro. The first application is in drug screening. “In our plan,” says Chen, “the liver-on-a-chip could be a novel drug screening and evaluation platform so that different kinds and concentrations of drugs could be employed cooperatively towards killing the carcinoma cells.”

For that application, the composite gel would be a substrate for hepatoma carcinoma cells, integrated in a microfluidic chip. A given structure—that is, a section built around a given size of silica nanoparticles—would have specific drugs loaded within the hydrogel. Each drug protocol would be color-coded according to the structure of the initial inverse-opal matrix. “The thermal heating process could heal the hydrogel,” Chen says, “but also contribute to the damage of carcinoma cells.” The healable hydrogel photonic crystal would then provide a path to identifying the optimum drug and thermal therapy to inhibit or prevent liver-cancer proliferation.

The long-term goal is to produce a durable scaffold for hepatocyte growth. Over time, according to Chen, the cultured cells gradually disintegrate the hydrogel network. This doesn’t affect the cells, but it destroys the optical capability of the substrate. The healable property, Chen summarizes, “mainly contributes in lengthening the service life of the substrate and further integrating biological functionality.”

About the Author

Richard Gaughan

Contributing Writer, BioOptics World

Richard Gaughan is the Owner of Mountain Optical Systems and a contributing writer for BioOptics World.