Lumotive and Himax collaborate on metasurface approach to beam steering for lidar

Automotive lidar developer Lumotive (Seattle, WA) and Himax Display (Tainan, Taiwan), a subsidiary of Himax Technologies (NASDAQ:HIMX), say that they are jointly developing beam-steering technology for autonomous-vehicle lidar that marries Himax's liquid-crystal-on-silicon (LCOS) technology with Lumotive's patented liquid crystal metasurfaces (LCMs) to improve the performance, reliability, and cost of lidar systems. Lumotive's lidar beam-steering approach will enable both advanced driver-assistance systems (ADASs) and fully autonomous vehicles such as “robo-taxis” and self-driving trucks, says Lumotive.

For autonomous driving systems, leading-edge lidar systems need advanced beam steering to deliver high performance and commercial viability. Traditionally, lidar has relied on spinning bulk-optical assemblies, while newer breeds of lidar sensors use MEMS mirrors or optical phased arrays. However, both of these approaches lack performance due to the small optical aperture of MEMS mirrors and the low efficiency of phased arrays, says Lumotive. Lumotive will be taking advantage of Himax's tailor-made LCOS process to convert semiconductor chips into dynamic displays that steer laser pulses based on metamaterial surfaces, which are the basis of Lumotive's beam-steering technology.

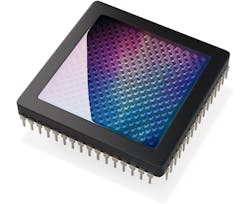

Lumotive's LCM chips contain no moving parts and are fabricated using mature semiconductor manufacturing processes and Himax's LCOS technology. Lumotive LCMs can be integrated into small form-factor systems, making them useful also for other applications in industrial and consumer sectors. Lumotive's lidar systems have an optical aperture of 25 x 25 mm for long range, 120-degree field-of-view with high angular resolution, and high-speed random-access beam steering.

Source: Lumotive

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.