Glass-on-glass 'microbottle' lasers can be tuned thermally or via stretching

Researchers at the Okinawa Institute of Science and Technology Graduate University (Okinawa, Japan) and Wuhan University of Technology (Wuhan, China) are fabricating small optically pumped glass-on-glass whispering-gallery-mode (WGM) lasers that offer an especially easy approach to thermal tuning.1

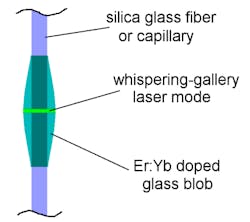

Making such a device, which the researchers call a microbottle laser, relies on the fact that the erbium:ytterbium (Er:Yb) doped glass serving as the gain material has a lower melting point than the silica fiber supporting it. To make a laser, A droplet of Er:Yb) glass heated by a carbon dioxide (CO2) laser is placed on the silica fiber, where the droplet spreads out and solidifies (see figure). These microbottle lasers have been made with diameters ranging from 22 μm to 232 μm.

When the Er:Yb doped glass outer layer is pumped with light at a 980 nm wavelength via a tapered optical fiber in contact with the doped layer, lasing is observed at 1535 nm (along with some green upconversion fluorescence from the Er ions) in a whispering-gallery mode occurring at the doped layer's widest point.

Tuning via air-cooling

Even more interesting, the laser can be fabricated on a capillary rather than a solid fiber; pumping air through the capillary at various rates cools the laser by varying degrees, allowing tuning with a flow sensitivity as high as 100 GHz/sccm (standard cubic centimeters per minute). In addition, the capillary (or a fiber-based version as well) can be stretched to strain-tune the laser by up to 50 GHz.

If liquid rather than gas is flowed through the capillary, the laser can serve as a sensitive instrument to measure fluid flow -- for example, at a water flow-rate sensitivity of 1 GHz/(nL/sec) in a capillary with an inner diameter of 100 μm.

In the future, the researchers want to create other types of lasers by flowing doped glass into pre-etched channels in silica glass.

REFERENCE:

1. Jonathan M. War et al., arXiv:1601.05493v1, 21 January, 2016).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.