Nanoscale modifications of optical-fiber diameter create super-high Q whispering-gallery resonators

Somerset, NJ--Researchers at OFS Laboratories have developed a sub-melting-point fabrication technique to modify the diameter of conventional optical fiber, creating high Q (quality factor) microresonators.1 The resonators can store light long enough to serve as optical memories for photonic computing circuits.

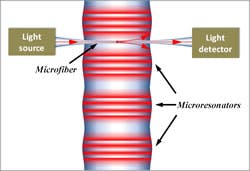

Light is coupled into the fiber in a whispering-gallery (diameter-skimming) mode perpendicular to the fiber's axis. The light is coupled in using an input tapered fiber tip placed close enough to achieve evanescent coupling. What the researches have done is create nanoscale bulges and waists along the fiber (see figure); each bulge confines the light, sending it on a back-and-forth corkscrew path inside a length of the bulge, creating a naturally light-confining microresonator.

0.01 nm precision

Using their sub-melting-point technique, Misha Sumetsky, a researcher at OFS Laboratories, and his colleagues were able to vary the optical fiber diameter by several nanometers. They did this with unprecedented precision, on the order of a hundredth of a nanometer.

It's possible to create these nanoscale changes to the radius of the fiber by exploiting a property inherent in the fiber created during manufacturing and discovered at OFS Laboratories several years ago. Optical fiber is made by heating a preform with a precise chemical makeup and drawing it. When the fiber is drawn out, the process introduces tension in portions of the fiber; this tension is frozen in, creating a predetermined amount of stress.

Releasing intrinsic stresses

The researchers harnessed this fixed stress by heating the fiber using CO2 laser and UV excimer laser beam exposures. By raising the fiber's temperature, but keeping it well below the melting point, it was possible to release this intrinsic pressure, changing the diameter and refractive index of the fiber without deforming it any further. As long as the fiber is produced under the same conditions and it is heated below the melting point, the same effect is always achieved. This process enables a technology that the researchers call surface nanoscale axial photonics (SNAP).

"In the new system, the accuracy of the fiber radius variation is about 0.1 angstrom—orders of magnitude better than achieved before," said Sumetsky.

Previous attempts have been made at harnessing optical fiber for microresonators, but these relied on polishing or melting the fiber to change its diameter. This produced very uneven results and could not achieve nanoscale dimensions. To enable evanescent coupling, it's vital that the circumference of the microresonators be controlled to sub-angstrom accuracy. The SNAP process ensures this accuracy and that each microresonator is nearly identical.

This is the crucial point the researchers believe will enable the technology to move from laboratory studies to manufacturing. As long as the optical fiber is produced under the same conditions, it will always produce the same effect when heated, changing its properties in the same manner. "We can faithfully reproduce these resonators. There's a real, robust way of fabricating these, and this is the first paper that actually shows that," says Sumetsky.

According to the researchers, it's possible these microresonators could be used in specialized devices in about two to three years. However, their greatest potential may be in pioneering optical computing and in enabling fundamental physics research.

REFERENCE:

1. M. Sumetsky et al., Optics Letters, Vol. 36, Issue 24, pp. 4824-4826 (2011).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.