Pressurized semiconductor membrane becomes widely tunable light emitter

There is more than one way to create a tunable laser. The first, which is commonly used, is to introduce a spectrally selective optical element into the laser system that can be tuned to pick out a subset of the laser’s entire gain spectrum. The second is to actually alter the spectral position of the laser gain output—for example, by changing the temperature of the laser gain material or by mechanically straining the gain medium. An innovative way to achieve the latter approach has been developed by researchers at Boston University (Boston, MA), the University of Wisconsin-Madison, and Sandia National Laboratories (Albuquerque, NM). Starting with a single-crystal semiconductor membrane, the researchers stretch the membrane by pressurizing it. Using an indium gallium arsenide (InGaAs) membrane as a light emitter (though, at least in this experiment, not as a laser), the researchers could shift the bandgap energy, and thus the photoluminescence (PL) center wavelength, by more than 250 nm in the near-infrared.

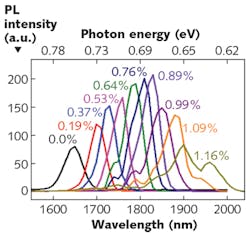

The 5 × 5 mm, 100-nm-thick (001) In0.53Ga0.47As film, which is anneal-bonded to a 125-μm-thick flexible film of Kapton polyimide, is mounted to a rigid cell that can be pressurized with gas. Various pressures ranging from 0 to 620 kPa over ambient pressure are applied, producing a strain of up to 1.1%. The membrane is optically pumped by a tunable optical parametric oscillator (OPO) supplying pulses at a 1100 nm wavelength, 5 ns duration, 20 Hz repetition rate, and 0.5 mW average power, focused to a spot size on the membrane of about 1 mm. Measurements with a room-temperature extended-range InGaAs photodetector show a red shift as the pressure increases, as well as some broadening of the PL bandwidth. Future versions, more easily tunable using piezo or MEMS actuators, could form the basis for widely tunable semiconductor lasers. X. Wang et al., Appl. Phys. Lett. (2018); https://doi.org/10.1063/1.5055869.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.