One of several techniques available for modulating the output beam of a laser is Q-switching. Modulation can be done using either electro-optic (E-O) or acousto-optic (A-O) materials (see Laser Focus World, May 1996, p. 127). Previous discussions on electro-optic modulation touched briefly on E-O Q-switching. This article will look at acousto-optic methods of Q-switching. The traditional markets for these switches are flashlamp-pumped solid-state lasers, but the growth today is mainly in the various applications for Q-switched diode-pumped solid-state (DPSS) lasers.

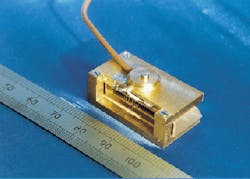

This Product Focus briefly reviews the theory of Q-switching. Many versions of A-O Q-switches are available commercially, and custom-designed solutions are also possible (see Fig. 1). There are important criteria involved in choosing an A-O Q-switch, and these will be reviewed. The article also covers some of the uses of Q-switches, looking at solid-state lasers, both diode-pumped and flashlamp-pumped systems. A representative listing of suppliers of acousto-optic Q-switches follows on p. 151. A more comprehensive inventory is available in the 1997 Laser Focus World Buyers Guide, beginning on p. 282.

Q-switch design

In Q-switching, the energy is stored in the population inversion of the lasing medium, building up in the laser cavity until the Q-switch is activated. Once activated, the stored energy is then released in a single pulse. There are several types of Q-switches, including A-O, E-O, mechanical, and dye. An A-O Q-switch consists of a block of optical material that is transparent at the desired lasing frequency. Quartz, fused silica (SiO2), flint glass, and tellurium dioxide are all materials that have been used commercially for Q-switches. Special uses for some of these materials will be reviewed later.

A piezoelectric transducer is bonded to the side of the optical block. The transducer material is usually a crystalline material such as lithium niobate. The bonding can be done by epoxy or vacuum metallic bonding. The acoustical signal is generated by the radio-frequency (RF) driver. When the signal is generated, it creates a sound wave through the medium, acting as a disturbance to the incoming beam. The beam is defracted in a predictable pattern out of the laser cavity, reducing the quality, or "Q," of the resonator, allowing the energy to build up. When the sound wave stops, the beam is no longer diffracted. Then the energy escapes the laser in a single pulse.

Selection of a particular type of Q-switch is dependent upon the type of laser, its characteristics, and performance parameters. The first criterion is that the laser be a type that can be Q-switched. Only lasers with an upper-state lifetime that is long enough to prevent spontaneous energy emissions can be Q-switched. These are solid-state lasers, generally Nd:YAG. Other lasers that can be Q-switched include the traditional ruby and glass as well as newer crystalline materials such as neodymium-doped vanadate (Nd:YVO4), neodymium-doped yttrium lithium fluoride (Nd:YLF), and holmium. Gas lasers, such as CO2 or ion lasers, are not usually Q-switched.

The second criterion for using an A-O Q-switch is that the laser must be a low-gain laser. The diffraction pattern generated by the acousto-optic switch does not remove all of the light from the cavity. If the laser gain is great enough, then even a small amount of feedback can override the Q-switch, causing the laser to lase. Once it is clear that an A-O Q-switch is both possible and desirable, then other criteria come into play. These include whether the beam is multimode or single-mode, polarized or unpolarized, and how divergent the beam is.

Different Q-switch designs are available to accommodate each choice. Diode-pumped solid-state lasers are treated differently than flashlamp-pumped systems, because of the smaller beam diameter, the higher gain, and the tight packaging requirements.

Intended usage of the laser/Q-switch system is another important criterion. Some systems will be used in industrial applications 24 hours a day, seven days a week. These systems must be reliable and durable. In many cases, they must also be able to handle high laser power. Other applications are in research laboratories, where continuous, demanding usage may not be as significant a concern.

Next come the actual performance specifications of the Q-switch. The user should be aware that an A-O Q-switch allows for a much lower insertion loss but can accommodate a much lower gain than an E-O Q-switch. It is important to convey to the manufacturer how much power the Q-switch will have to accommodate. Cooling methods are also a consideration because some systems require water cooling to remove the excess heat, while for others air cooling is sufficient. There are also choices as to whether the optics have an antireflection coating or if they are mounted at Brewster`s angle for minimal reflection. Damage thresholds of the coatings also affect performance and must be considered for high-power systems.

The design and performance of the RF driver should merit some consideration as well. If the driver has CE approval (certified for sale in the European Union), then it will most likely meet shielding standards for emissions at the primary and harmonic electronic frequencies. Some drivers provide a level of diagnostics, informing users when the temperature has gone too high or when the power levels are outside of acceptable ranges. Key features are the amount of RF power required to drive the Q-switch and the risetime/ falltime of the RF pulse. In some designs, the RF driver is integrated with the Q-switch, reducing both cost and space requirements while improving performance.

Applications

The most common use for the acousto-optic Q-switch is still the flashlamp-pumped Nd:YAG system. As much as 80% of the A-O Q-switches sold are for this use, either with new lasers or as replacement parts for existing systems. Many of these systems are for industrial applications, that is, cutting, trimming, and machining of metals including, for example, marking parts in an automotive assembly plant. The lasers are in operation for three shifts a day, every day. The Q-switches are in dirty environments; it is difficult to keep the lasers sealed and clean, however, the Q-switches do not fail in a mechanical or electrical manner. The debris and dust in the environment are burnt onto the optics, rendering the switch useless. These shops will usually replace the Q-switch at the same time that they replace damaged optics, because the engineer or service person has already made the trip, and the system is down.

In DPSS systems, A-O Q-switched lasers have the predominant market share for pulsed products. Commercial electronics applications include precision micromachining and thin-film trimming. The trimming applications include the well-established memory repair, as well as trimming the sensor for air bags and gold coatings on quartz watches. Newer applications that have been receiving much interest include laser texturizing of magnetic recording disks and rapid prototyping for model building (see Fig. 2). The rapid-prototyping application requires a frequency-tripled, Q-switched diode-pumped Nd:YVO4 laser, run at such high repetition rates, 20-40 kHz, that the liquid polymer reacts to the pulsed laser as if it were the output from a CW source.As DPSS systems continue to increase in power, additional applications open up. At the Semicon West conference (July 1996, San Francisco, CA), several companies introduced systems for thick-film resistor trimming. The systems are based upon an A-O Q-switched DPSS laser. According to Curt Frederickson of Spectra-Physics Lasers (Mountain View, CA), one of the manufacturers that uses A-O Q-switches in its DPSS systems, "As the power levels of diode-pumped lasers continue to increase, additional applications will continue to develop. It is unlikely that DPSS systems will completely replace the arc-lamp-pumped Nd:YAG lasers as a pulsed source of high power."

Research is still a significant market for acousto-optic Q-switches, not with the flashlamp-pumped Nd:YAG systems, but with some of the newer crystalline materials. Holmium-doped YAG, Nd:YLF, and Nd:YVO4 are facilitating research at new wavelengths and with new processes. Investigations with Ti:sapphire systems also requires acousto-optic Q-switches. These crystals have stimulated research in new Q-switching materials, including the tellurium oxide (TeO2) used with the DPSS systems.

Q-switches for DPSS systems have several unique requirements. The entire package must be very small, as well as providing a very short optical length to accommodate the small size of the laser system (see Fig. 3). These switches are air-cooled, because the laser system has no water-cooling requirements itself. It must provide a high diffraction efficiency, while operating with relatively low RF power from the driver. In some cases, it must hold off high optical power as well.More than three-quarters of the A-O Q-switch purchasers are laser manufacturers and systems integrators who work with the switch manufacturers to create custom products that meet the specific technical needs of each particular laser. Reliability and durability, cost and delivery are all important concerns for these buyers. The other major group of purchasers are the industrial users who buy replacement Q-switches. They are looking for compatibility with their current systems as well as low cost and availability.