Microstructured fluorotellurite fiber produces 1.4 to 4 µm supercontinuum

Fiber-based coherent supercontinuum (SC) light sources that emit in the mid-infrared (mid-IR) have uses in the life sciences—for example, in molecular spectroscopy, nonlinear microscopy, and optical coherence tomography (OCT). Mid-IR SC sources based on numerous pump wavelengths, optical-fiber materials, and geometries have been invented and fabricated, each with different spectral outputs and their own advantages and disadvantages. In the interests of further expanding this field, scientists from Jilin University (Changchun, China), Chinese Academy of Science (Shanghai, China), Tianjin University (Tianjin, China), and Toyota Technological Institute (Nagoya, Japan) have created yet another new type of mid-IR SC fiber, this one demonstrating coherent SC light output over a spectrum extending from 1.4 to 4 μm in a single device. The fiber material and geometry, microstructured fluorotellurite glass, shows good chemical and thermal stability.

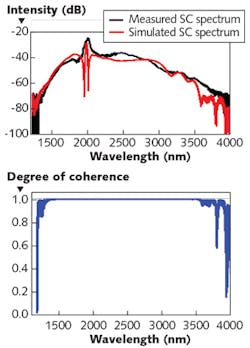

The fiber's suspended core has six webs connecting the core to the cladding. The 4-cm-long experimental fiber had a section containing a taper with a transition region length of 1.4 cm. Over this section, the core diameter tapered smoothly from 3.6 to 0.8 μm. A femtosecond fiber laser, described as "homemade" and emitting 170 fs pulses with a peak power of 3.6 kW at a 1980 nm wavelength, was used as the pump source. The measured SC spectrum closely matched the simulated SC spectrum, and the degree of coherence across most of the spectral output band was very close to 1. The researchers say that the spectral broadening in the supercontinuum source was caused by self-phase modulation, soliton fission, and red-shifted dispersive wave generation. Reference: N. Li et al., Appl. Phys. Lett., 110, 061102 (2017); http://dx.doi.org/10.1063/1.4975678.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.