Basics of ultrafast lasers: Part 1

Imagine gazing out your window on a sunny spring afternoon. As you admire the green trees and blossoming flowers, you see a small blur dart past. You follow the motion until the blur finally pauses, and you realize it is a beautiful hummingbird—the first of the season! You pull out your phone to capture this beacon of warmer weather in a photo for your social media, only to startle the hummingbird with the sound of the capture button. A photo that once held the promise of many “likes” is now a giant blur across your screen.

Similar frustrations motivated the development of ultrafast lasers within the scientific community. Instead of capturing a fluttering hummingbird, these lasers with pulse durations on the order of femtoseconds to picoseconds (10-15–10-12 seconds) are used to capture events like molecular vibrations,1 electronic motion,2 and even quantum phenomena.3 At timescales of one millionth of a billionth of a second, ultrafast lasers continue to expand our access to fundamental physical phenomena, as well as revolutionize industrial processes.

Unique features of ultrafast lasers

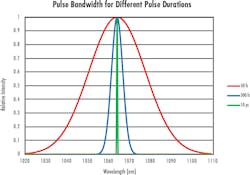

Thanks to their ultrashort pulse durations, ultrafast lasers possess key features that distinguish them from longer pulse or continuous-wave (CW) lasers. Generating such a short pulse requires a broad spectral bandwidth. The minimum bandwidth to generate a pulse of a particular duration depends on the pulse shape and the central wavelength. In general, this relationship is described by the time-bandwidth product (TBP), which arises from the uncertainty principle. For a Gaussian pulse, the TBP is given by:

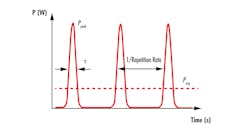

Beyond broad spectral bandwidths, incredibly high peak powers are another consequence of ultrashort pulse durations. For context, let’s examine the difference in the peak power output of a 10 W CW laser vs. that of a 10 W ultrafast laser with 150 fs pulses and a repetition rate of 80 MHz—properties common for many commercially available ultrafast laser sources.

In the case of the CW laser, its average power and peak power are the same: the laser always emits 10 W, or 10 J/s. In the case of the ultrafast laser, the average power is still 10 W, equal to that of the CW laser. The difference between these two sources is the ultrafast laser is emitting that 10 W of average power over only a small fraction of time. Figure 2 demonstrates the difference between average power and peak power.For the ultrafast laser, that 10 W is distributed across the 80 million pulses emitted each second, according to the repetition rate. At first glance, the sub-microjoule pulse energy of this laser may seem miniscule. But if we account for this energy being squeezed into only 150 fs of time, we arrive at a massive peak power of over 800,000 W for this laser, which is more than four orders of magnitude greater than the average power. While such enormously high peak powers and broad spectral bandwidths have made ultrafast lasers useful for a wide variety of application spaces, these features also give rise to some of their unique technical challenges.

Technical challenges of ultrafast lasers

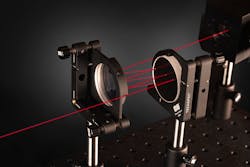

Broad spectral bandwidths, incredibly high peak powers, and the ultrashort pulse durations of ultrafast lasers must be considered and properly managed when applying an ultrafast laser to your project or process. Typically, the simplest of these is managing the broad spectral output of your laser. If you have mostly worked with CW or longer pulsed lasers in the past, your inventory of optical components may not reflect or transmit the entire bandwidth of your ultrafast laser pulse. The good news is many suppliers keep these needs in mind when designing ultrafast laser optics, so it is quite easy to source mirrors, lenses, and other optical components that sufficiently cover the bandwidth of ultrafast lasers.

The laser damage threshold (LDT) of optical components is another important distinction between ultrafast and other lasers that can pose a challenge for ultrafast laser users (see Fig. 3). When sourcing optical components for nanosecond lasers, it is common to see laser damage thresholds on the order of 5–10 J/cm2. For ultrafast optics, values this large are practically unheard of; you are more likely to see LDT values < 1 J/cm2, typically closer to 0.3 J/cm2. This dramatic difference in LDT values across different laser pulse durations reflects the different mechanisms for laser damage at play.

For nanosecond lasers or even longer pulses, the predominant damage mechanism is thermal in nature. In these cases, the material is absorbing incident photons and heating up, which can result in deformation of the lattice. Effects like thermal expansion, lattice strain, cracking, and melting are common outcomes for thermal pathways of laser damage.5 In the case of ultrafast lasers, the duration of the pulse itself is actually faster than the timescale of heat transfer into the surrounding material lattice. Instead, the high peak powers of ultrafast lasers shift the damage mechanism toward more nonlinear pathways, such as multiphoton absorption and ionization.6 For these same reasons, one cannot scale the LDT rating for nanosecond pulses down for ultrafast pulses. As a result, the most appropriate optic for your particular application is one with a sufficiently high LDT rating obtained under the same conditions (laser wavelength, pulse duration, repetition rate, etc.) it will experience in your application.

One of the most difficult technical challenges associated with ultrafast lasers is maintaining the ultrashort pulse duration provided by your laser. Ultrashort pulses are highly susceptible to temporal distortion, which worsens as the pulse duration gets shorter. Though your laser may emit a 50 fs pulse, relaying this pulse to a target position using mirrors and lenses, or even just passing it through air, has the potential to temporally broaden your ultrafast pulse.

In the ultrafast community, we quantify this temporal distortion as group delay dispersion (GDD). GDD is a frequency-dependent value that, for a given material, scales linearly with thickness. Transmissive optical components like windows, lenses, and objectives normally apply positive GDD so your once-compressed pulse may emerge from the transmissive optical component with a longer duration than initially emitted by your laser.

For longer pulses, such as nanosecond and even picosecond pulse durations, GDD is not a major concern. In the case of femtosecond pulses, however, even 10 mm of N-BK7 in the path of your laser beam can broaden a 50 fs pulse centered at 800 nm by over 12%. This is roughly equivalent to having two windows or filters in the path of your beam. Because of this tendency toward temporal distortion, it is recommended to use specialized ultrafast optics that impart minimal to no additional GDD and decrease the chances of an elongated pulse duration.

Ultrafast laser applications

The ultrashort pulse durations and high peak powers of ultrafast lasers provide benefits to a wide variety of applications, including:

Spectroscopy. Since the inception of the ultrafast laser, its application in spectroscopy has been ubiquitous. By decreasing the pulse duration down to femtosecond timescales, dynamic processes in physics, chemistry, and biology were suddenly observable.7 The advent of ultrafast lasers has provided access to atomic motions—improving our understanding of fundamental processes ranging from molecular vibrations and dissociation all the way to energy transfer in photosynthetic proteins.8

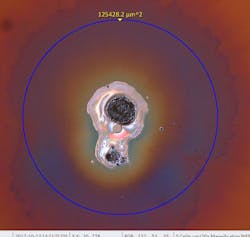

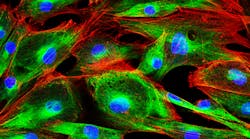

Biological imaging. The very high peak powers of ultrafast lasers support nonlinear processes that can improve the resolution of biological imaging, such as in the case of multiphoton microscopy. In these studies, it is necessary to overlap two photons in both space and time to generate the nonlinear signal from the biological medium or fluorescent target. This nonlinear mechanism improves the imaging resolution by substantially reducing the signal background that plagues studies conducted with single photon processes.9 Figure 4 demonstrates how this reduced background can result in higher resolution.

Laser materials processing. Ultrafast lasers have revolutionized the laser micromachining and materials processing worlds because of their ultrashort pulse durations. As mentioned in the context of LDT, the duration of the ultrafast laser pulse itself is faster than the time scale of thermal diffusion into a material’s lattice. As compared to nanosecond pulsed lasers, this means an ultrafast laser produces a much smaller heat-affected zone, resulting in lower kerf loss and more precise machining.10 This principle extends to the medical field as well, where the increased precision of ultrafast lasers cuts is routinely used to decrease damage to surrounding tissues and improve the patient experience.11

Future of ultrafast lasers: shorter pulses

As research into the applications of ultrafast lasers continues, so too does development of new and improved ultrafast laser sources. To gain insight into even faster physical processes, many researchers are turning their attention to the generation of attosecond pulses—pulses on the order of 10-18 seconds in the extreme ultraviolet (XUV) spectral region.

Studies to track electronic motion are already being conducted using these even shorter ultrafast pulses, and the field of attosecond science continues to improve our understanding of electronic structure and quantum mechanics.12 While integration of XUV attosecond pulses into industrial processes has not yet gained major traction, continued research and advancements in this field will almost certainly propel this technology out of the lab and onto the manufacturing floor, as has been the case with femtosecond and picosecond laser sources.

REFERENCES

1. J. Bredenbeck et al., J. Am. Chem. Soc., 126, 5, 990–991 (2004).

2. F. V. A. Camargo et al., Nano Lett., 21, 3, 1461–1468 (2021).

3. M. Maiuri et al., J. Am. Chem. Soc., 142, 3–15 (2020).

4. P. Lazaridis et al., Opt. Lett., 20, 10, 1160–1162 (1995).

5. R. Wood, Laser-Induced Damage in Optical Materials, 9–24 (2014).

6. X. Jing et al., Opt. Express, 17, 26, 24137–24152 (2009).

7. O. Geßner et al., Sci. Rep., 311, 219–222 (2006).

8. D. Zigmantas et al., Chem. Phys. Rev., 3, 041303 (2022).

9. C. J. R. Sheppard, J. Biomed. Opt., 1, 014511 (2020).

10. K. C. Phillips et al., Adv. Opt. Photon., 7, 4, 684–712 (2015).

11. C. L. Hoy et al., IEEE J. Select. Topics Quantum Electron., 20, 7100814 (2014).

12. J. Li et al., Nat. Commun., 11, 2748 (2020).

About the Author

Olivia Wheeler

Olivia Wheeler, Ph.D., is an ultrafast laser optics engineer at Edmund Optics (Barrington, NJ).