Enhance your Nd-doped DPSS laser with a longer-wavelength pump

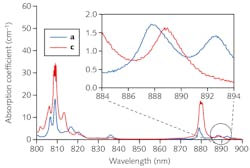

Neodymium (Nd) doped crystals such as Nd:YAG and Nd:YVO4 were among the earliest solid-state lasers to achieve commercial success. For a number of years, the crystal gain medium in these lasers was optically pumped with flashlamps. These lasers were very inefficient, in part because the flashlamps produced a broad continuum of wavelengths, whereas the Nd ions have an absorption spectrum consisting of sharp bands and lines (see Fig. 1). As a result, most of the pump light was wasted as heat, requiring aggressive water cooling of the crystal. Then, the maturation of long-lived power-scalable laser diodes enabled the revolutionary development of the diode-pumped solid-state (DPSS) laser, in which laser diodes designed to emit at a 808 nm wavelength are used as the pump, matching a strong absorption peak of Nd.

The reliability and long lifetime of DPSS lasers, which are often Q-switched, has supported an ever-growing list of industrial applications, from manufacturing medical devices to packaging of integrated circuits. Increasingly, these applications have relied on frequency doubling and tripling of the near-infrared fundamental wavelength to deliver green and UV output for optimized micromachining processes. Most of these DPSS lasers are end-pumped; by using fiber-coupled laser diodes, the laser diodes can be placed remotely from the laser cavity, simplifying service and lowering the heat budget in the laser head. Fiber delivery also enables good mode overlap between the pump and the desirable TEM00 mode in the DPSS laser.

The DPSS thermal challenge

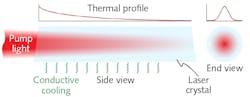

However, heat inherently produced in the laser crystal itself eventually limited the development of end-pumped DPSS lasers for applications needing higher power together with a TEM00 beam (good beam quality is also vital to enabling efficient second harmonic, or SHG, and third harmonic, or THG, generation). Compared to a laser diode, for example, a DPSS laser pumped at 808 nm is surprisingly inefficient. One big reason for this is the large quantum defect, which is the energy difference between the 808 nm pump photons and the 1064 nm Nd output. (In technical terms, 808 nm pumping causes Nd to act as a four-level laser, a type that is notorious for inefficiency.) Moreover, this excess heat generated in the gain crystal limits how large the crystal can be for conductively cooling the crystal via its surfaces with flowing water. In addition, the heating causes thermal lensing in the crystal, changing its focal properties as the laser power is varied (see Fig. 2). This compromises the output mode quality, resulting in lower SHG/THG efficiency, and limits the achievable precision and edge quality in some cutting, drilling, and scribing applications of these lasers.The heating is also localized near the pump input facet, with limited penetration deeper into the crystal because the pump light is so strongly absorbed. This effect can be partially mitigated, at the cost of complexity, by pumping the crystal from both ends. Nonetheless, typical DPSS lasers use crystals only 8 mm or less in length and are limited in output power, with acceptable beam quality only at one optimum power level. This performance negatively impacts the throughput and materials thickness in a growing number of applications.

Lower quantum defect, three-level efficiency

Market demand for higher power together with high beam quality has pushed laser designers back to the drawing board. This effort has resulted in a solution based on pumping Nd via the relatively weak absorption peaks around 880 nm that can be seen in Figure 1. Specifically, laser diode pump modules are now available to pump Nd at three “new” wavelengths: 878.6 nm, 885 nm, and 888 nm. The wavelength is maintained at the target value in each case by integrating a volume Bragg grating (VBG) within the packaged laser diode modules, eliminating the need for precise control of the laser diode temperature. All of these long wavelengths offer several advantages over the legacy 808 nm pump wavelength, with the 888 nm in particular delivering additional important polarization-related benefits.

The first advantage of using these long wavelengths is the significant reduction in the quantum defect by over 50% compared to 808 nm pumping. As a direct result, the unwanted heat due to this aspect is reduced by the same amount. In addition, the DPSS laser now acts as a quasi-three-level laser, which is inherently more efficient than the four-level process driven by 808 nm pumping. The bottom line is that more of the pump power is converted into DPSS output, with less thermal waste to accommodate.

Lower absorption, higher pump volume

While it may seem counterintuitive, another important efficiency advantage arises from the fact that the Nd absorption peaks are much lower at 880 nm than 808 nm. The reduced absorption strength enables the pump light to penetrate much further into the gain crystal (see Fig. 3). This increases the pump volume, which is the volume in which the light is absorbed and, as a result, the volume in which the unwanted heat is generated.Thus, long-wavelength pumping results in less heat, and this heat is spread over a larger volume. This combination therefore allows the use of longer crystals (for example, 30 mm) that can also be safely pumped at high power with less thermal lensing—and hence better beam quality over a wider range of output powers. The end result is the emergence of a new generation of Q-switched DPSS lasers, particularly in the green and UV, with the power needed to better exploit numerous micromachining applications.

888 nm optimum pump wavelength

The laser crystal normally is pumped along its b-axis, for a variety of reasons. For 808 nm and 880 nm, the resulting absorption in the a- and c-axes is very different and is much stronger when the light is polarized along the c-axis, as shown in Figure 1. The problem is that fiber-delivered pump light is naturally unpolarized. Thus, if the pump light from the fiber is focused directly into the crystal, the crystal doping and crystal length cannot be fully optimized for the pump power and for targeted DPSS laser operation characteristics.

If the crystal is optimized for a-axis absorption, then half the light will penetrate too far into the crystal. Conversely, if the crystal is optimized for c-axis absorption, then half the light will not penetrate deeply enough. To solve this conundrum, the light from the fiber is usually divided by a polarization-cube beamsplitter. The 50% with the “wrong” polarization is relayed to the opposite end of the gain crystal and a wave plate is used to rotate its polarization by 90° so that all the pump power is absorbed with the same strength. Such a pumping scheme is very sensitive to polarization changes caused by moving the fiber, which can lead to dramatic changes of the degree of pump absorption in the crystal and therefore power instabilities of the DPSS laser.

At 888 nm, however, the absorption is very similar for polarization along the a- and c-axes, as in Figure 1. In addition, the small difference varies only slightly with wavelength at this point on the Nd absorption spectrum. As a result, the pump light can be coupled into the crystal directly from the fiber with no need for relay optics and a waveplate, and no need for duplication of the focusing and dichroic optics needed for pumping both ends. Furthermore, sensitivity to fiber movement is dramatically reduced and negligible. (Coherent holds a patent for pumping DPSS lasers at 888 nm—patent # 8,913,644—but a license is automatically included with each pump-diode module supplied by Coherent at these new wavelengths.)

The weak dependence of absorption strength relative to small wavelength changes at 888 nm delivers another very important benefit: active wavelength locking of the pumps, including tight temperature control, is no longer critical for stable DPSS output. This simplifies the laser and lowers component and assembly costs. (Passive wavelength stabilization using an integrated VBG is still preferred, since this minimizes any wavelength shift due to changes in diode drive current, leading to an even wider performance range.) The end result is that the power of the DPSS laser scales linearly with diode drive current at 888 nm. This is a very valuable characteristic for any application where modulation is needed or where the power has to be varied for any reason.

Single-emitter architecture

Coherent recently launched a new family of fiber-coupled diode modules—called FACTOR—with a choice of all three new wavelengths: 878.6, 885, and 888 nm. Several technical aspects of these merit examination. First, these are based on a single-emitter format. Each module contains a series of these single emitters, all on a common baseplate and all aligned for coupling into the single permanently attached output fiber. Why single emitters? As already described, efficiency is a key benefit of long-wavelength pumping, delivering higher power, better beam quality, linear modulation, lower costs, and a lower carbon footprint for greener manufacturing. The use of single emitters that are thermally discrete enables very effective cooling of the diodes. In turn, this allows the diodes to be operated close to their maximum power without fear of thermal degradation or truncated lifetime. This minimizes the total number of emitters needed, lowering component costs for the DPSS manufacturer. The single-emitter output is also easier to couple into a fiber. In combination with a sophisticated fiber-coupling concept, these new modules from the FACTOR series will offer outstanding coupling efficiency, further increasing DPSS efficiency.

Manufacturing fiber-coupled pump modules based on single-emitter architecture is not without its challenges, but vertical integration at Coherent has provided solutions to all of these. In addition to assembling and testing these modules, Coherent makes all the key components in-house, from the wafers used to make the laser diodes to the VBG filters to the delivery fiber and so on. Having total control over the production of these components ensures high reliability and longevity in addition to high performance.

About the Author

Joerg Neukum

Director of Product Marketing, High Power Diode Lasers at Coherent

Joerg Neukum is Director of Product Marketing, High Power Diode Lasers at Coherent (Mainz, Germany).

Florian Lenhardt

Product Line Manager, Coherent

Florian Lenhardt is Product Line Manager at Coherent (Mainz, Germany).