High-harmonic generation sources enable extreme ultraviolet lensless imaging

High-harmonic generation (HHG) is blazingly fast attosecond science, enabling imaging electronic motion within matter on the scale of a quintillionth of a second. At the Advanced Research Center for Nanolithography (ARCNL; Amsterdam, Netherlands), a group of researchers who work on lensless imaging are using computational methods to enable imaging with minimal requirements to optical components.1 The main idea behind their approach is that the light that diffracts from an object contains all of the information about that object—even if that light is not detected within the image plane of a microscope.

The big challenge is then to retrieve that information from a diffraction pattern, but it turns out this is actually possible in many cases. This means that the simplest imaging system can consist of only a coherent light source and an image sensor, which can be extremely compact. And the researchers report that this approach also works for wavelength ranges where high-numerical-aperture (high-NA) optics are extremely challenging, such as extreme ultraviolet (EUV) or soft x-ray radiation.

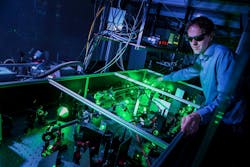

“High-harmonic sources can provide fully coherent EUV beams from a tabletop system, which fits in my lab and to which we have unlimited access,” says Stefan Witte, group leader EUV Generation and Imaging for ARCNL (see Fig. 1). This makes high-harmonic sources “a great source for EUV lensless imaging systems.”

High-resolution EUV imaging is extremely beneficial for the entire realm of nanoscience, and in particular the semiconductor industry, because shorter wavelengths enable higher resolution than visible-light microscopes. It can also penetrate layers of materials that are opaque to visible light, including various metals such as titanium, nickel, copper, and silicon nitride.

Witte’s inspiration for this work and ultimate goal is to make EUV microscopes a reality, and then to explore their potential for nanoimaging.

High-order harmonic generation basics

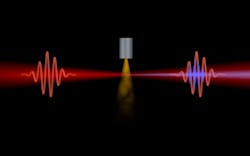

HHG involves using a laser system capable of producing intense ultrashort laser pulses, which are focused into a gas of atoms contained within a jet or a small cell. This gas needs to be surrounded by a vacuum environment or else the produced HHG would quickly be absorbed into the air (see Fig. 2).Technologically, HHG means developing more-powerful lasers working at higher repetition rates, and controlling the laser-gas interaction to optimize the conversion efficiency from laser energy to HHG. “This last aspect involves developing new gas-target geometries, but changing laser wavelength has also been shown to be an important parameter,” says Witte.

As can be imagined, plenty of surprises emerge when working with HHG. Most of them “come from the extremely nonlinear nature of the HHG process, which makes it a challenge to really fully understand and know your source,” Witte notes.

But what Witte finds most surprising is the degree of coherence of the beams being produced. “If you look at the three-step method and the extreme fields involved, it’s amazing that the end result is an EUV beam with near-perfect coherence properties,” he says. “This still makes it a good choice for experiments that require a well-defined phase of the incident light (such as diffractive imaging)—even if the flux is low compared to plasma sources or synchrotron beamlines.”

Professor Kjeld Eikema, who works with Witte at ARCNL, also leads the Ultrafast Laser Physics and Precision Metrology group for Vrije University Amsterdam, where he uses HHG for precision microscopy on atoms and ions to test fundamental physics such as quantum electrodynamics (QED) and theory.

“I find it amazing that the HHG process is so coherent—despite the brutal process where an electron is ‘ripped off’ an atom and then slammed back to generate new light,” Eikema says. “Because the whole process is tightly linked to the phase of the fundamental wave, both spatially and temporally, you get really nice laser-like beams out of it, and incredible timing precision of the generated new electromagnetic waves. It’s really a wonderful tool that enables things like precision spectroscopy, attosecond science, and imaging at extreme-ultraviolet wavelengths.”

Potential for imaging, nanolithography, metrology

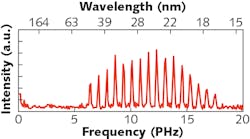

Witte’s group recently explored the effective use of the full spectrum of HHG sources for imaging, nanolithography, and semiconductor metrology. “HHG sources naturally produce extremely broad spectra that can span a large bandwidth across the EUV and soft x-ray range,” he says. “This large bandwidth can be used to accurately measure wavelength-dependent differences in absorption and refractive index within a single experiment.”

Another important goal for the researchers at ARCNL is to develop spectrally resolved lensless imaging methods, providing the ability to take images of nanoscale objects for a wide range of EUV wavelengths. “HHG sources are a compact source of broadband coherent EUV radiation, and are the key component for such an ‘EUV color microscope,’” says Witte.

How far along is this work? “We actually already have some proof-of-concept measurements showing that we can separate different materials in an image taken with a broadband HHG source,” explains Witte. “I believe all of the different elements will work, and the main challenge is to push this approach to higher resolutions, shorter wavelength, and improved sensitivity. It’s my hope that within the next three to five years we will be able to show element-sensitive imaging at a 20–50 nm spatial resolution, as well as 3D imaging of nanostructures with HHG sources.”

One big hurdle ahead is improving HHG flux (number of photons per second) to be able to measure faster and get brighter images, Witte says, but another is how to get the spectral resolution given that there are no simple “color filters” for HHG. To tackle these challenges, the researchers are combining imaging with Fourier-transform spectroscopy, which is a method commonly used for molecular spectroscopy and biophysics that they’re now trying to get to work for HHG. “We’re getting interesting results already,” he adds.

Peter Kraus, who is a group leader of HHG and EUV science at ARCNL, also views the achievable flux and highest photon energy that can be generated as the biggest challenges for using HHG. “More flux is always better, because it allows you to measure faster,” he says. “The relatively low fluxes from HHG still pose severe limitations to both spectroscopy and imaging applications.”

For imaging, “the shortest possible wavelength (highest photon energy) is often desirable,” Kraus explains. “And for spectroscopy you often want broadly tunable and high photon energies to cover resonant transitions from core-level electrons to the valence orbitals.”

HHG with 1 keV photon energies (approximately a 1 nm wavelength) has already been demonstrated, but the fluxes are low. “Achieving such high photon energies at appreciable fluxes is a huge challenge,” Kraus says. “But it will open up more fundamental applications and more widespread use in industry.”

Real-world applications

Several research groups around the globe are already showing HHG-based lensless imaging’s potential for characterizing nanostructures—ranging from biological objects to semiconductor devices—in great detail. “It may enable noninvasive characterization of 3D nanostructures, including the ability for spatial mapping of elemental composition,” Witte says. “This has all sorts of applications for science and industry, within basically every field that involves nanostructures and nanodevices.”

Witte believes that short-wavelength radiation shows great promise for metrology. “There are no other methods that allow you to really look inside nanostructures,” he points out. “Electron microscopes, for instance, have amazing resolution but cannot provide any penetration depth and are therefore mostly limited to imaging surfaces.”

For now, the biggest hurdle to any application of HHG is the stability and user-friendliness of sources. “I’m not aware of any industrial use of HHG, and that’s mainly because HHG systems nowadays are based on large and complex high-power lasers, with a lot of free-space beam path and the associated precise alignment requirements,” Witte notes. “Until a few years ago, you couldn’t buy a complete HHG system; you would have needed to build your own. At this point it’s not yet something you put in a factory, turn on, and let run all day. But that situation is rapidly improving, and there are a few companies now selling complete HHG systems.”

REFERENCE

1. G. S. M. Jansen et al., Opt. Lett. (2019); https://doi.org/10.1364/OL.44.003625.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.