High-pulse-energy fiber laser is an eye-safe source for lidar and sensing

JIHONG GENG, SHIBIN JIANG, and ANTHONY W. YU

Fiber lasers routinely achieve multikilowatt average output power levels in a continuous-wave (CW) mode and in a compact package, expanding the available opportunities for industrial and military applications.1 Compared to CW fiber lasers, however, pulsed fiber lasers are not receiving equal acceptance in many practical applications; in short, their potential would improve dramatically if they could deliver short optical pulses with sufficiently high energy and high peak power.

One such important pulsed application is coherent lidar for wind measurement, laser spectroscopy for remote chemical sensing, and target ranging or identification, which requires transform-limited-linewidth laser pulses with a relatively long pulse duration (several-hundred nanoseconds) and a high pulse energy in a nearly diffraction-limited laser beam.

In terms of compactness, robustness, and the flexibility of pulse tailoring, a fiber-based pulsed laser would be much more favorable than its free-space optical counterparts when deploying a coherent lidar system for field applications on the ground or in the air. The advantages come from a fiber laser’s all-fiber monolithic design: a master oscillator power amplifier (MOPA) configuration with a fiber-coupled seed laser providing a well-tailored laser pulse format and a fiber amplifier chain providing needed laser energy.

A similar fiber-based pulsed MOPA platform with different seed laser formats can be used for either coherent lidar or direct time-of-flight (ToF) lidar applications. For coherent lidar, a seed laser is typically operated in CW mode in combination with an external fiber-pigtailed amplitude modulator (an acousto-optic [AOM] or electro-optic [EOM]) to generate transform-limited-linewidth laser pulses (hundreds of nanosecond durations) for coherent detection. For ToF lidar, a directly modulated laser diode can provide very short seed laser pulses (<5 ns) for direct detection.

But despite these obvious advantages, the main obstacle to deploying monolithic pulsed fiber lasers in lidar applications is the limitation in pulse energy and peak power due to nonlinear effects from the optical fiber at the heart of these sources.

Increasing fiber laser pulse power

Commercially available high-power pulsed fiber lasers/amplifiers typically use silica-glass-based step-index large-mode-area gain fiber with a few-meter fiber length in their last-stage fiber power amplifiers, thereby generating desired output pulse energy. Unfortunately, stimulated Brillouin scattering (SBS) effects in this meters-long last-stage gain fiber limits the maximum output energy of transform-limited-linewidth laser pulses (with 100 ns or so pulse width) to around <200 µJ with fair beam quality.

Although a rod-like photonic crystal fiber (PCF) with a very large core diameter (80–100 µm) has demonstrated the potential to increase the maximum pulse energy up to the millijoule level, PCF is not widely accepted in commercial pulsed fiber laser systems.2 The PCF option primarily lacks the robustness and compactness of a solid-core fiber scheme due to its fragile, free-space signal/pump optical coupling requirements.

For the past several years, AdValue Photonics (Tucson, AZ) has developed a proprietary multicomponent glass fiber laser technology that achieves >1 mJ pulse energies from hundreds-of-nanoseconds-duration, transform-limited-linewidth laser pulses. This performance has been demonstrated at multiple wavelength bands (1 µm, 1.55 µm, and 2 µm). Similarly, high pulse energy with a much-shorter pulse duration (2–5 ns) can also be generated from an all-fiber laser system with a relatively broad spectral bandwidth, which could be useful for ToF lidar applications.3

AdValue Photonics has delivered these high-energy pulsed fiber lasers to industrial companies and government labs for applications in remote sensing and lidar by leveraging volume manufacture of its rare-earth-ion-doped silicate glass fibers that provide very high optical gain and single-mode output from a short piece of large-mode-area fiber. The fiber laser increases the onset thresholds of nonlinear optical effects through an enlarged fiber core diameter (30–50 µm) and minimized gain fiber length (tens of centimeters) with high doping concentration while still maintaining single-mode operation.

Eye-safe 1550 nm band

Of the three wavelength bands noted, fiber-based pulsed laser sources operating in the 1550 nm telecommunications wavelength band are particularly favorable to lidar. Beyond the obvious eye safety and low atmospheric attenuation of this band, the 1550 nm region offers commercial availability of telecom-grade imaging sensors with high speed, high resolution, and high sensitivity (without active cooling) at relatively low cost.

A fiber-based laser source at 1550 nm can be built with erbium (Er)-doped fiber, co-doped with ytterbium (Yb) ions by taking advantage of the existence of an efficient energy transfer process from Yb to Er ions. That is, with an Yb ion first photoexcited from its 2F7/2 ground state to its 2F5/2 excited state by absorbing light at 980 nm, this excited Yb ion in the 2F5/2 state can efficiently exchange its energy with its surrounding Er ions initially in the 4I15/2 ground state.

During the process of energy exchange/transfer, the Yb ion loses energy and transitions back to its 2F7/2 ground state; simultaneously, the Er ion gains an equal amount of energy and transitions up to its 4I11/2 excited state. Because the rapid energy transfer process from Yb ions to Er ions dramatically promotes the excitation of Er ions, this Er-Yb co-doping yields higher laser efficiency at 1550 nm with Er ion emission.

Increasing the doping concentrations of Yb and Er ions can further increase pump absorption and optical gain even within a short piece of gain fiber. The shorter the gain fiber, the better the mitigation of nonlinear optical effects when building a high-power or high-energy pulsed fiber laser.

Spectral output modification through fiber doping

The last-stage amplifier for the millijoule-level all-fiber laser system from AdValue Photonics uses a silicate-glass double-clad polarization-maintaining Er/Yb-doped optical fiber (see Fig. 1). Although the 45 µm core diameter of this large-mode-area gain fiber is much larger than that of most commercially available fiber counterparts, the laser output beam maintains nearly diffraction-limited performance due to the unique doping attributes and <0.04 numerical aperture of the fiber.

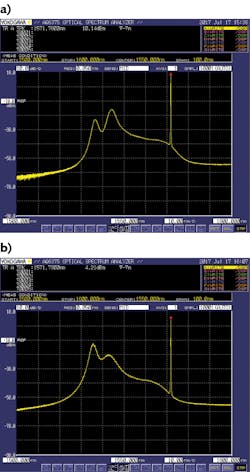

Not only can multicomponent silica glass fibers tolerate high doping concentrations to increase pump absorption and optical gain, but the fiber design and doping profile can also modify the spectral behavior of the fiber laser. Within the C-band (1530–1565 nm), the spectral output of a heavily Er/Yb-doped gain fiber is significantly different than a commercially available single-mode telecom-grade optical fiber (see Fig. 2).Doped fibers can exhibit around 6 dB higher gain and nearly 10 dB higher signal-to-noise ratio (SNR) than commercial silica fibers in a 1572 nm-seeded amplifier configuration. Incidentally, 1572 nm is a key wavelength for sensing carbon dioxide (CO2) in the atmosphere. As compared to other absorption lines of CO2, this 1572 nm line is relatively insensitive to temperature changes, exhibits minor absorption interference by other atmospheric species, and allows space-borne measurements without concerns for absorption saturation.

Sensing applications

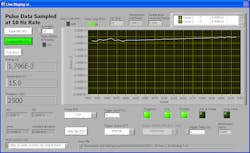

While it is extremely challenging to build a high-energy, all-fiber, alignment-free pulsed laser at 1572 nm—far from the Er-ion emission peaks around 1535 and 1545 nm (see Fig. 2)—AdValue Photonics has demonstrated such a pulsed transmitter option for a NASA space application that reaches pulse energy values as high as 1.8 mJ at 2.5 kHz (see Fig. 3).4The NASA Goddard application requires this particular laser source to meet the sensing requirements for the NASA Active Sensing of CO2 Emissions over Nights, Days, and Seasons (ASCENDS) mission. Sensing with a CO2 absorption line near 1572 nm is one of the two possible technical approaches for the ASCENDS mission, with an alternative approach using a CO2 absorption line near 2050 nm.

For coherent lidar applications, information is typically sensed by optical heterodyning a local oscillator with a returned sensing light, which is typically backscattered or backreflected from remote objects when illuminated with a coherent laser beam. The sensing information can be either a Doppler frequency shift of the return light, backscattered by aerosol particles in the atmosphere for wind measurement or CO2 molecules in the atmosphere for chemical remote sensing, or phase change of the scattered/reflected light by a remote hard target for vibration fingerprint identification. When using a coherent pulsed laser for illumination, coherent lidar can yield location information of a sensing object—similar to ToF lidar.

Although the AdValue Photonics doped fibers have a complex gain profile and spectral output, the fibers themselves are easily coupled to the pigtail fibers of most commercial fiber-based optical components. The high similarity in glass material structure allows easy fusion splicing between the doped gain fibers and other components such as pump combiners, optical isolators, and spectral filters, enabling a >1 mJ all-fiber monolithic pulsed fiber laser that is well suited to field deployment for coherent lidar and sensing applications (see Fig. 4).REFERENCES

1. Y. Kawahito et al., Opt. Lett., 43, 19, 4667–4670 (2018).

2. C. D. Brooks and F. Di Teodoro, Opt. Express, 13, 22, 8999–9002 (2005).

3. W. Lee et al., IEEE Photon. Technol. Lett., 31, 18, 1534–1537 (2019).

4. W. Lee et al., Opt. Lett., 43, 10, 2264–2267 (2018).

Jihong Geng is chief scientist and Shibin Jiang is president, both at AdValue Photonics, Tucson, AZ; e-mail: [email protected]; www.advaluephotonics.com, while Anthony W. Yu is a physicist in the Lasers and Electro-Optics branch at NASA Goddard Space Flight Center, Greenbelt, MD; e-mail: [email protected]; http://nasa.gov/goddard.