Femtosecond lasers: From inception to industrial applications

SAMI HENDOW

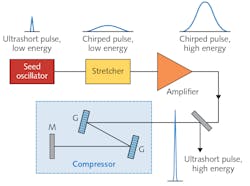

The 2018 Nobel Prize in Physics was awarded to Arthur Ashkin, Gérard Mourou, and Donna Strickland for groundbreaking inventions in laser physics.1 In particular, Mourou and Strickland were awarded the Nobel Prize for their method of generating high-intensity ultrashort optical pulses. This method is commonly referred to as chirped-pulse amplification (CPA; see Fig. 1). This award was not only for recognition of the novelty of CPA in the scientific community, but also for the impact it has had on laser industries. Currently, CPA is the dominant means for generating femtosecond pulses.

Interest in creating and using increasingly shorter and more intense laser pulses has been high. However, physical barriers exist that prevent such pulses from being highly amplified in solid-state amplifiers, as well as in optical fibers. As pulses get shorter and peak powers build up, optical nonlinearities are encountered that limit the peak optical power propagating in materials. Coherent light scattering caused by the optical nonlinear effect reduces the efficiency of the amplifier and results in other undesirable outcomes. More importantly, however, the high peak power of the intense laser pulses reaches the material-damage threshold of the components in the amplifier system.

CPA bypasses these limitations by stretching the laser pulses prior to amplification by using a long fiber or a pair of diffraction gratings (see Fig. 1). After amplification of the stretched pulse—kept well below the optical damage threshold of the amplifier components—a grating pair is arranged such that the long wavelength of the pulse travels a shorter optical path than the short wavelength, reversing the earlier pulse stretching. This concept provides a way to create high-energy ultrafast laser pulses, opening up many scientific applications followed by industrial applications.

Background

In the early 1990s, the titanium:sapphire (Ti:sapphire) laser was a popular tool for the research market. Its wide tunable bandwidth, short pulses, and high energy enabled the investigation of many novel applications. Multiphoton imaging has been one of the successful applications benefited by this capability.

Despite the achievements, this early technology was not widely deployed commercially because of its size and complexity. Along with the industry’s optical telecommunications development, fiber-based femtosecond laser technology improved enough to partially overcome the shortcomings of the Ti:sapphire laser, but had limited success due to the still-present low power and pulse energy. Finally, CPA technology combined with the advancement of fiber lasers enabled market applications and opportunities previously unattainable.

Since the invention of CPA was made public, numerous academic and commercial entities have used this concept in applications that continue to amaze and benefit many. In 1999, Ahmed Zewail of Caltech (Pasadena, CA) was awarded the Nobel Prize in Chemistry for his studies of the transition states of chemical reactions using femtosecond spectroscopy.

The first sizable-scale implementation of the femtosecond laser in a nonscientific application was in the ophthalmology area. High-intensity femtosecond pulses are an ideal tool for separating transparent biological tissues without thermal damage. The creation of a corneal flap by a femtosecond laser before reshaping the corneal stroma with an excimer laser was commercialized for vision correction.

Today, all-femtosecond laser corneal vision correction is possible. The fiber-based CPA (or FCPA) has been shown to be ideal for such advanced ophthalmic applications because of its optical performances supported by its reliability.

The economic slowdown of the early 2000s made way for the development of several new technologies. Paramount of these were the interest in high-power laser sources, which galvanized interest in cladding-pumped fiber amplifiers and higher-power solid-state lasers. Early applications of these included component and instrument testing, as well as material damage analysis with its accompanying defense-related applications.

Materials processing

In the meantime, picosecond pulsed lasers for materials processing became recognized as superior to nanosecond lasers for machining materials. The use of picosecond pulses reduced thermal damage of the material and thus (by mid-2000) enabled a wider penetration of lasers in the manufacturing industry, such as for marking, drilling, and cutting.

However, it had been recognized and demonstrated that femtosecond lasers are “required” for many applications due to the technology’s enabling characteristics, as well as its significant improvement in materials processing. IMRA America first produced microjoule-level femtosecond FCPA-based lasers commercially for materials processing in 2002.2 Based on fiber technology, the FCPA emerged as a common means for building high-peak-power, high-average-power, and high-pulse-energy femtosecond lasers.

In general, the level of heat-affected zone (HAZ) reduction provided by femtosecond pulsed lasers is unmatched by other lasers. The near-surgical delivery of energy to the workpiece opened the door for the use of FCPA in delicate consumer electronics parts manufacturing, including in the display industries.

The application of femtosecond lasers to dicing silicon wafers has been of continuing interest, as the high peak power of a femtosecond laser pulse can be used to ablate silicon and other deposited materials on the surface of the wafer with minimal collateral or thermal damage to adjacent components. Typically, dicing channels are preconfigured on these wafers. These channels are also used for probing and testing of chips prior to their singulation. Consequently, dicing channels are populated with sensors and probing points. In this case, the femtosecond beam is used to remove those extra surface layers as well as to support stealth dicing of the wafer. Femtosecond lasers are also ideal for singulation of high-brightness LED chips from a sapphire wafer, due to the uniquely strong nonlinear absorption of femtosecond laser pulses in a hard, transparent sapphire substrate.

Glass processing

The dominant method for cutting and finishing glass in the consumer electronics industry has been by mechanical means. Nevertheless, applications are emerging for processing glass using femtosecond pulsed lasers. Via hole-drilling is one example, whereby the glass is exposed to a femtosecond optical beam, causing a change in the index. The glass is then etched in an acid bath that removes the exposed area. Such parts are used in multichip platforms, creating highly dense and fast chip connectivity structures that enable vertically integrated ICs.

Another application is patterning and removal of thin film coating on glass, as is done with conductive indium tin oxide (ITO) films, electrochromic films, and other films.

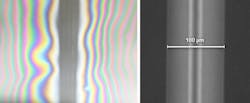

Glass welding is of interest to many, as it does not involve the use of bonding agents or fillers. This is important for the microelectronics packaging industry because it removes the issue of internal contamination and outgassing and eliminates the need for the use of getters (substances added specifically to absorb such unwanted materials). In the process, two glass parts are optically contacted and exposed to a femtosecond beam: the high peak power of the femtosecond pulse induces multiphoton absorption in the glass, melts the glass locally, and welds the two parts together, producing a durable hermetic seal (see Fig. 2).

Automotive industry

The use of femtosecond pulsed lasers in manufacturing will continue to evolve and expand. The automotive industry is of particular interest because it demands high stability and reliability along with innovation. For example, femtosecond lasers are currently used in high-volume conditioning of engine parts, including pistons (see Fig. 3).

The push to improve fuel economy in cars is propelling efforts to reduce vehicle weight and improve operating efficiency. Engines are made of lighter aluminum alloys, while surface texturing and hatching is applied to moving parts for friction reduction and durability improvement. The use of these alloys makes it imperative to engineer solutions that reduce wear and promote lifetime. In comparison to other techniques such as mechanically ruling the surface, marking by longer-pulse lasers, or surface shot peening, femtosecond-laser crosshatching of a surface is shown to efficiently diffuse the associated oil film and significantly improve oil retention.

This texturing is typically applied to the skirt area of the piston, which experiences the majority of the contact, and is shown to reduce friction by up to 25% at 2000 rpm. The use of femtosecond lasers also eliminates the formation of burrs on the scribed areas, therefore eliminating the requirement for a deburring process and further improving manufacturing efficiency.

The commercialization of FCPA in various markets ranging from medical to automotive has been a constant driver for the engineering of reliable and innovative products. The combination of application-specific reliability and testing standards with those of the laser industry and the evolution of test protocols have enabled nonstop operation in demanding markets.ACKNOWLEDGEMENT

The author would like to acknowledge the help of Emily Grish and Jason Alexander with this article.

REFERENCES

1. D. Strickland and G. Mourou, Opt. Commun., 56, 3, 219 (Dec. 1, 1985).

2. See http://bit.ly/femtosecondref2.

Sami Hendow is associate director of the Applications Development Center at IMRA America, Fremont, CA; e-mail: [email protected]; www.imra.com.