Laser Micromachining: Shaped femtosecond laser pulses improve ultrafast-micromachining quality

In an open paper whose free distribution may help many an ultrafast-laser machining outfit to improve its manufacturing process, scientists from Beijing Institute of Technology (Beijing, China), the University of Minnesota (Minneapolis, MN), and the University of Nebraska-Lincoln have summarized their research showing how shaping femtosecond laser pulses can improve the quality of the microfabrication process (see figure).1 Specifically, they show that the technique improves “fabrication precision, quality, throughput, and repeatability and effectively control micro/nanoscale structures.”

This is not just theory; the group also provides an extensive list of experimental examples. The technique was also used to fabricate microstructures in a Chinese project. The researchers’ results, and their list of accomplishments, are the culmination of a 10-year project.

Electron dynamics control

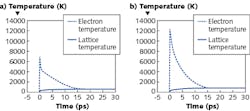

Because the interaction of a femtosecond laser with a material is so short timewise, it is dominated by the photon-electron iterations, rather than any resulting lattice motion, which happens on a longer picosecond time scale. Thus, shaping the pulses to alter these electron dynamics can alter the fabrication process. The hard part is determining what pulse shape for what process.

To simulate electron dynamics control (EDC), the researchers used four different theoretical models: calculations for electron dynamics, a molecular dynamics simulation for phase change, a plasma model for ionization processes, and a two-temperature model for energy transport.

Based on the simulation results, the researchers experimented with temporally and spatially shaping femtosecond pulses, creating subpulses that have a pulse delay shorter than the characteristic time scale of electron-lattice coupling. With an amplified Ti:sapphire laser from Spectra-Physics (Santa Clara, CA) as a light source, the pulses in the experimental setup were shaped using a commercial 4f-configuration-based pulse shaper by Biophotonic Solutions (East Lansing, MI). The sample was mounted on a stage with a 1 μm accuracy made by PI (Karlsruhe, Germany).

Results could be of wide use

Using the processes they developed, the researchers achieved some stunning results through their project, including: 1) increasing the processing efficiency of microchannel fabrication by 56X and the maximum aspect ratio of the microchannels by 3X; 2) boosting a laser-assisted chemical etching rate by 37X; 3) adjusting the periods, orientations, and structures of surface ripples by adjusting electron generation on fabricated material surfaces; 4) creating surface-enhanced Raman spectroscopy (SERS) surfaces with enhancement factors up to 1.1 × 109; and 5) fabricating deep-subwavelength (~1/14 of laser wavelength) and high conductivity (~1/4 of bulk gold) nanowires in open air.

In just one specific, the sensitivity of SERS substrates, which is because of an enhancement of the electromagnetic field in the vicinity of the surface microstructures by surface plasmon resonance, was boosted because the EDC process allowed tailoring of the surface structures into ordered nanopillar arrays rather than the conventional subwavelength ripples.

The researchers also experimented with spatial pulse shaping, changing the beam’s Gaussian profile to other shapes using a phase-based spatial light modulator. A dual-peak-shaped beam spot was one result, which allowed the high-precision formation of nanowires in a gold film. Using spatial pulse shaping to create Bessel beams (so-called “nondiffracting” beams), EDC was also used to fabricate structures such as taper-free microholes with a diameter of 1.6 μm and an aspect ratio of 330:1.

The group has developed techniques to measure EDC fundamentals that includes a pump-probe shadow-graph imaging technique, time-resolved plasma photography, laser-induced breakdown spectroscopy, and a commercial fast-imaging CCD.

REFERENCE

1. L. Jiang et al., Light Sci. Appl. (2018); doi:10.1038/lsa.2017.134.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.