Blue industrial laser brings speed, quality, and efficiency to metal 3D printing

When the first commercially available blue industrial laser shipped more than five years ago, it began transforming materials processing applications. Its rapid adoption followed, built on the fact that all metals absorb blue light much better than infrared (IR) light—especially copper, aluminum, and gold, which are all highly reflective in the IR. This fundamental physical advantage leads directly to improved performance for metal-processing applications. It first made an impact in welding, where enhanced light absorption leads directly to improved weld speed and part quality. The blue laser is now introducing these same advantages to additive manufacturing.

Additive manufacturing began as a method of producing prototype parts from plastics and other polymers. Although helpful for checking form, fit, and function, this limited range of materials forces an equally limited range of applications. Only with the extension of additive manufacturing to the fabrication of metal parts could the applications be extended. Blue industrial laser technology has now advanced to allow integration into laser-based 3D-metal-printing methods, such as direct-energy deposition (DED) and powder bed fusion (PBF).

Additive manufacturing presents some unique challenges the blue laser is tailored to overcome. For example, the build speed, efficiency, and quality of blue laser 3D printing opens the possibility of mass production. Advances in both laser technology and additive manufacturing processes will stimulate further growth and enable novel applications.

A foundation in fundamental physics

The electronic structure of metal atoms dictates their interaction with electromagnetic radiation. For a wide range of reflective metals—copper, aluminum, gold, and others—their inherent atomic structure makes them very poor absorbers of IR radiation. Consequently, very high IR power densities are required to even initiate energy transfer into metals. At low IR power density, IR light is simply reflected off the surface.

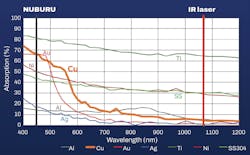

As the power density is increased, the beam forms a hole in the part, with the IR radiation reflecting many times off the sides of the hole, which results in a dramatic increase in absorption. This dramatic increase leads to a runaway condition, with increased absorption leading to violent vaporization—creating voids and spatter that result in a poor-quality weld. Conversely, as seen in Figure 1, these same metals absorb blue light very well. Consequently, melting reflective metals with blue laser energy is a smooth, well-controlled process.

For an application like welding, the goal is to produce a mechanically (and sometimes electrically) robust joint, characterized by an even, continuous weld. With the precise process control offered by the blue laser, a wide selection of speed, spot size, beam energy, and other parameters will produce a high-quality weld. This means different combinations of metals, thicknesses, and part geometries can be accommodated. In contrast, with the IR laser the window for these process parameters is extremely tight, which not only limits productivity but is sometimes so tight it’s impossible to achieve a high-quality weld using an IR laser.

Additive manufacturing of metals is essentially sequential welding done on a small scale. Feedstock is presented and an energy source melts the raw material, joining it to adjacent material. Laser-based additive manufacturing is attractive for the same reasons lasers are optimal solutions in many applications: they flexibly and reliably deliver energy to a precise location without requiring any physical contact between laser and material. DED and PBF are alternative approaches to presenting the feedstock. DED, for example, directs the feedstock to the laser printhead, while PBF deposits a uniform layer of powdered material over which the laser moves in a specified pattern.

The same fundamental physics of welding apply: poor absorption of reflective metals such as copper, gold, and aluminum presents IR laser-additive manufacturing with two challenges. First, when melting reflective materials with a high-intensity IR laser beam, there is a substantial amount of vaporization of the smaller powder particles, which leads to the need to manage the redeposition of these vaporized particles.

Second, if using a ring laser, a significant amount of energy is wasted preheating the powder ahead of the higher-brightness laser source.

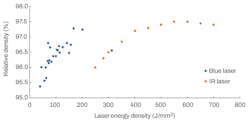

Blue light is predictably absorbed by most metals, so a lower-brightness laser can be used to create a well-controlled melt puddle and vaporization can be minimized. This provides a means to scale up multilaser systems without having to resort to complex gas flow management schemes. Consequently, blue lasers can provide high part densities, higher printing speeds, and a means for scaling up production speeds with multiple parallel lasers. As shown in Figure 2, the blue laser produces equivalent-density 3D-printed metal parts more efficiently than IR sources.Beyond theory

Although fundamental physics is a necessary element of the blue industrial laser’s success in materials processing applications, realizing the promise requires real-world engineering. Early tests of blue laser performance in both DED and PBF machines demonstrate the concrete ad-vantages blue holds over IR. For example, copper blocks fabricated with both methods reached greater than 97% density, and showed excellent surface quality and dimensional accuracy, while stainless steel test coupons had a minimum density of 98%, all prior to process optimization.

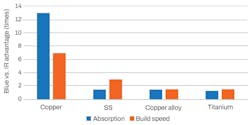

Representative quantitative improvements of blue over IR are summarized in Figure 3. The key metric of build rate efficiency—essentially a measure of fabrication speed per watt—was also demonstrated to be anywhere from 1.4X to greater than 7X better than IR. These advantages are consistent for stainless steel, titanium, copper, and GrCop alloy, and demonstrate the foundation for growth into additional application areas.Present capabilities, future possibilities

Since its introduction in 2017, blue industrial laser specifications have rapidly improved. Achieving key metrics for power and brightness expanded the scope of applications. The early models excelled at applications in battery cell fabrication, where dozens or scores of thin foils must be joined with good mechanical strength and uncompromised electrical fidelity.

Building on that early success, as the blue laser reached higher levels of output power—crossing the 500 W, then 1000 W milestones—its application range expanded as well. For example, it became possible to join battery foils, tabs, busbars, and cases with a single laser system. Additional advances made it possible to integrate the laser with standard industrial scanning systems, introducing efficiencies that enabled rapid throughput at high quality for consumer electronics applications. These applications, in turn, stimulated the development of processes for joining electric vehicle components, and into aerospace and medical applications. To this point, laser improvements and process developments have paralleled each other, and that trend is sure to continue with additive manufacturing.

We anticipate much of the development in automotive and similar applications will focus on process optimization to further enhance the volumetric printing efficiency. The blue laser technology under development today will greatly support the future expansion of additive manufacturing by providing higher print speeds, with high resolution and high quality. Higher-brightness blue lasers will have a direct impact on today’s 3D printers by providing a plug-and-play replacement for IR lasers—resulting in an immediate improvement in performance and breadth of materials that can be printed. Figure 5 shows the straightforward integration of a blue laser into a commercial 3D printer.Steady rapid improvement

The next leap in industrial blue laser capabilities will come with area printing, which is a very promising technology but still in the early stages of development—a development NUBURU is pursuing in the context of a U.S. Air Force demonstration contract. The parallel continuing enhancement of the blue laser and parameter optimization for processes such as area printing will face the same challenges as any new technology development. Technical performance improvements are essential to application growth for any new product, but logistics must also support market needs. The blue industrial laser’s materials processing advantages are leading to rapid adoption across a range of industries, which is—of necessity—requiring changes in the supply chain; but as those changes take place, additional blue laser applications will open up in other industries, such as healthcare, display, and bioinstrumentation.

With past history as an indicator, the growth promised by the blue laser seems almost inevitable. Additive manufacturing offers efficiencies in material utilization, rapid time-to-market for innovative designs across industries, and significant net reductions in operations and maintenance costs. But these advantages cannot be realized if metal 3D printing remains expensive and slow. The blue industrial laser removes these barriers to offer rapid, economical, high-quality fabrication of metal parts, and enables additive manufacturing to fulfill its promise.

About the Author

Mark Zediker

Co-Founder and Chairman of the Board, Nuburu

Mark Zediker is Co-Founder and Chairman of the Board at Nuburu (Centennial, CO).

Jean-Michel Pelaprat

Co-Founder and Chief Marketing & Sales Officer, Nuburu

Jean-Michel Pelaprat is Co-Founder and Chief Marketing & Sales Officer at Nuburu (Centennial, CO).