Pattern-transfer nanomanufacturing for micro-optics and spectroscopy

RYAN J. PRIORE

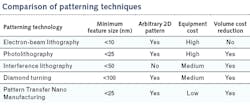

Patterned nanoscale structures hold tremendous promise for both the life-science and photonics industries. Such structures will enable substrates capable of capturing specific biological chemistries, optics to be directly integrated onto the tip of a fiber optic, and the next generation of polarizers and antireflective coatings using metasurfaces on flat or curved surfaces. To create 2D patterned structures at the nanoscale, companies presently use cleanroom microlithography originally developed for transistor manufacturing. Interference, photo-, and electron-beam lithography all have limitations when used for creating arbitrary 2D nanoscale structures in addition to more traditional optical fabrication tooling like diamond turning (see table).

Step 1: Pattern write

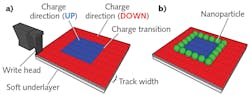

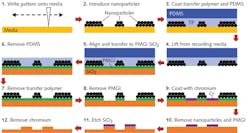

A magnetic recording write/read head is brought into physical contact with perpendicular magnetic recording media. A high-resolution x-y translation stage moves the recording head back and forth across the recording media. Lubrication is used to reduce the friction between the recording head and the media. By switching the sign of the electric current injected into the recording head coil, a user-defined 2D template is created by controlling the magnetic transitions (that is, junctions between oppositely recorded regions) with high spatial resolution. The created template is stable for 10 years and can be erased/rerecorded if necessary.

Nanoparticle suspension solutions may be created by dispersing magnetic nanoparticles, which are uniform distributions with a magnetite (Fe3O4) particle diameter available from 10 to 30 nm, in solvents with appropriate concentrations. Custom-made magnetic nanoparticles such as magnetic core/gold shell particles may be used for applications requiring appropriate surface properties.

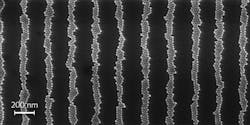

Once the 2D template is introduced into a magnetic nanoparticle suspension, the nanoparticles self-assemble along the magnetic transitions to create the final master pattern (see Fig. 3). The magnetic-field strength gradient at the transition can reach as high as 25 MT m-1 at 10 nm above the surface, resulting in nanoparticles firmly affixed to the substrate media.2 Functionalized magnetic particles may also be utilized at this point to create custom life-science substrates based directly on the recording media (as opposed to carrying out the additional steps 2 and 3) for either spatial isolation of a sample or purification.REFERENCES

1. L. Ye et al., Adv. Funct. Mater., 26, 3983–3989 (2016).

2. L. Ye et al., Sci. Rep., 6, 23145, 1–9 (2016).

Ryan J. Priore is chief technology officer at CIRTEMO, Columbia, SC; e-mail: [email protected]; www.cirtemo.com. (Please note that as of May 1, 2019, CIRTEMO has joined the Thorlabs organization.)