Fiber Sensing: Optical fiber monitors the arterial networks of commerce

DAVID HILL

The world economy now relies on the efficient use of a global network of highways, railroads, and pipelines to transport people, products, and resources across countries and continents. Alongside these networks, fiber-optic communication cables are often present, containing spare optical fiber that can be accessed to provide continuous, gapless monitoring and act as a "nervous system" for the world's "arterial" networks of commerce.

Distributed acoustic sensing (DAS)—one form of fiber-optic sensing technology—first emerged around 10 years ago. Since then, it has rapidly progressed from the laboratory to widespread adoption in several real-world applications.

Originally conceived as a new form of security sensor, optical fiber buried around the perimeters of critical national infrastructure or along borders is being used to provide early detection of intruders. The oil and gas industry was also quick to recognize the potential of DAS and as a consequence, much success has been reported regarding how fiber deployed downhole in oil and gas wells is being used to monitor the effectiveness of hydraulic fracturing, for production flow monitoring, and for monitoring borehole seismic activity.1-3

Furthermore, it is apparent that the unique ability of DAS to monitor very long fibers that are already in situ provides a unique sensing capability for long linear assets where fiber is also present. Pipeline monitoring was identified as the main application, but more recently, DAS has been found to effectively monitor highways and railroads located next to optical fiber routes.

For all applications, the core platform technology is the same. Signals captured by the fibers are analyzed in real time at the point of collection to detect, locate, and classify events. Actionable information is then relayed to the operator. This information may be in the form of a threat alert, a report on the condition of the infrastructure, or the flow across the asset. The accuracy and immediacy of the information delivery is used to protect the asset, optimize its use, and reduce operating costs.

Distributed acoustic sensing

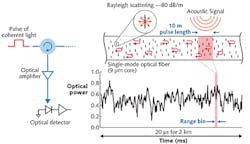

All DAS systems use a technique called coherent optical time-domain reflectometry (C-OTDR) that involves the successive transmission of short pulses of highly coherent light down an optical fiber and the observation of the very small levels of backscattered signal (see Fig. 1). The system relies on sensing the picostrain-level signatures in the fiber induced by vibro-acoustic disturbances originating from events in the vicinity of the fiber-optic cable.

These disturbances alter, on a molecular scale, scattering sites in the fiber core originating from sub-wavelength heterogeneities formed when the fiber was drawn. This results in a characteristic and interpretable modification to the Rayleigh backscattered laser signal that is analyzed at the interrogation unit (detection headend) to generate a series of independent, simultaneously sampled acoustic signals from along the fiber.

Each acoustic signal corresponds to a specific channel along the fiber whose spatial resolution (gauge length) is defined by injecting short (1-20 m) optical pulses that are spectrally narrow to achieve coherent interference over the spatial interferometer gauge length and also from pulse to pulse. That is, there is no change in the backscatter unless the optical phase delays between the scatterers change because of strain or change in index of refraction.

The output time series for all "virtual" strain sensors are formed by optical range bin sampling for 1 to 20 m channel separation at the pulse repetition frequency. No special reflectors or in-fiber Bragg gratings are needed for DAS and it is applicable to any unmodified standard single-mode optical fiber, including those in communication cables already in the ground.

Single-mode optical fibers up to 50 km (31 miles) in length can be used with the acoustic bandwidth of each channel limited only by the round-trip time for the cable length—1/2000 of a second for a 50 km cable. Using a 10 m spatial resolution, for example, will generate 4000 channels sampled at 2.5 kHz spanning a 40 km (25 miles)-long fiber deployed along a pipeline. Each time sample at 2.5 kHz will contain a snapshot of the acoustic field averaged over the 10 m section of cable at that particular sample section. Furthermore, these parameters are adjustable in software to optimize the sensing performance.

The first-order measurement of DAS is a change is optical phase for a given strain, which is induced in the fiber by second-order vibro-acoustic signals interacting with the fiber. Typically, DAS has a dynamic strain sensitivity of sub-nanometers within each gauge along the entire length of the fiber. This sensitivity corresponds to a particle displacement figure of approximately -90 dB m.s–2.Hz–½.

The thousands of channels of raw acoustic data formed at the interrogation unit are passed to a processing unit, where application-specific signal processing algorithms are applied in real time to extract the information relevant to the user's problem such as pipeline protection, perimeter or border monitoring, or seismic signals acquired on a fiber deployed in a well.

These alerts or other quantitative information are viewed by operators on a geographic information systems (GIS) overlay display at a control center and can be further relayed to higher-level command systems for integration with other sensors, or can be transmitted in a secure fashion over the Internet to a web server on which remote subscribed users can view the data on any web-enabled device.

Pipelines

When a new major transmission pipeline is buried, it is often the case that a fiber-optic telecommunication cable is deployed alongside. Using one of the fibers in this cable, it is possible to provide both pipeline damage detection and prevention capability.

Pipelines can be damaged unintentionally by backhoe digging or being struck by the bit of a horizontal boring machine. Intentional damage caused by hot tapping as a result of people stealing oil is another major issue that can cause pipeline shutdowns and result in punitive remediation costs.

By using DAS to monitor the fiber, it is possible to detect, locate, and classify activity that could be a potential threat to the pipeline. In most circumstances, this is the sound of either a person or machinery digging near the buried pipe. However, to ensure nuisance alarms are kept to a minimum, these sounds need to be accurately picked out of the cacophony of other sounds that occur because of benign activity within the vicinity of the buried pipe.

Given the high fidelity of the acoustic signals detected by DAS, sophisticated algorithms can be applied to recognize the acoustic signature of a threat. For instance, the sound of manual digging close to the buried pipeline is distinguished from the sound of cattle walking along the pipeline right of way, or the sound from a mechanical backhoe operating close to the pipeline is distinguished from the sound of a passing vehicle. This has proven very successful; so much so that today, tens of thousands of kilometers of pipeline are being continually monitored by DAS—reducing incidents of hot tapping and saving substantial costs that otherwise would have been incurred through loss of production (see Fig. 2).Because pipelines can also leak from fatigue, corrosion, geo-mechanical movement, or poor installation, DAS can monitor for leaks through real-time analysis of the acoustic data acquired using different algorithms looking for features such as negative pressure pulses, ground heave, orifice noise, and rapid temperature changes.4 It is now possible to identify and accurately locate leaks much smaller than has been possible with conventional, non-optical technology.

Highways

Given our reliance on highways for the movement of people and goods, it is somewhat surprising that the roads themselves are relatively "dumb" given the scarcity of sensors deployed to provide continuous, real-time, uninterrupted coverage of road and traffic conditions. Inductive loops are the conventional method of monitoring traffic flow along highways. However, the need to place the loops into the pavement and to provide roadside furniture to house the instrumentation makes it a costly approach.

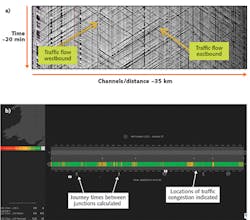

Alternatively, DAS is transforming roadway monitoring by using fiber within communications cables deployed alongside the highway to detect moving vehicles, with custom algorithms processing flow rate, journey times, and detecting traffic congestion (see Fig. 3).5Additional DAS applications are being considered to fulfill the vision of a "smart highway" infrastructure such as off-ramp monitoring, weigh-in-motion data collection, and pothole detection. The data gathered by the roadside fiber provides spatially resolved views of traffic and road conditions that can be fed back into existing traffic management systems, enabling highway authorities to respond faster to incidents and thereby increasing traffic throughput and shortening journey times.

Railroads

The railroad companies normally own their right-of-way and run their own and third-party cables. A fiber can be used in one of these cables running alongside the track to perform a number of functions currently accomplished by an assortment of different sensors, including security, condition monitoring, and signaling applications.The theft of trackside copper cables as well as the detection of unauthorized trackside activity represents security applications where DAS is being used, not to mention detection of flat wheels and rail breaks that can cause train derailment. The latter have recently been highlighted in the recommendations for action issued by the US Department of Transport Federal Railroad Authority.6

In other condition-monitoring applications, DAS is able to detect anomalies such as falling rocks along the tracks, where it is set to detect, with minimum nuisance alarms, rocks weighing 200 kg or more that could potentially derail a rail car, dropped from several meters at any point along the length of the fiber. However, it is in the area of signaling where DAS is likely to have the biggest impact. By being able to monitor the precise position and motion of each train in real time, trains can be managed by positive train control systems, thereby reducing journey times while increasing rail capacity and improving safety.

Further improvement in the capabilities of DAS that are currently in development will provide quantitative measurement with improved sensitivity and higher spatial resolution on longer lengths of sensing fiber. In addition, advances in the processing of the signals will provide better event detection and classification. By combining the hardware and signal processing capabilities of DAS, it is now possible to in effect build a nervous system for the pipelines, highways, railroads, and cable networks that we depend on for worldwide commerce and transport.

REFERENCES

1. M. M. Molenaar and B. E. Cox, "Field cases of hydraulic fracture stimulation diagnostics using fiber optic distributed acoustic sensing (DAS) measurements and analyses," SPE Middle East Unconventional Gas Conference & Exhibit, Muscat, Oman, paper SPE 164030 (Jan. 2013).

2. P. in't Panhuis et al., "Flow monitoring and production profiling using DAS," SPE ATCE, Amsterdam, the Netherlands, paper SPE 170917-MS (Oct. 2014).

3. A. Mateeva et al., Geophys. Prospect., 62, 4, 679–692 (Jul. 2014).

4. J. Worsley, "Fibre optic four mode leak detection for gas, liquids and multiphase products," ADIPEC, Abu Dhabi, United Arab Emirates, presentation 171824 (Nov. 2014).

5. R. Pinchen et al., "Congestion and incident management application for distributed acoustic sensing technology—NZTA case study," ITS Asia Pacific Forum, Auckland, New Zealand (Apr. 2014).

6. See www.fra.dot.gov/eLib/Details/L16322.

David Hill is chief technology officer and a co-founder of OptaSense, Farnborough, Hampshire, England; e-mail: [email protected]; www.optasense.com.