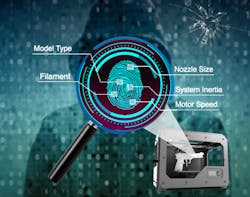

Image-filtering method 'fingerprints' 3D printer source for objects like 3D-printed guns

Like fingerprints, no 3D printer is exactly the same. That's the takeaway from a new University at Buffalo (UB; Buffalo, NY)-led study that describes what's believed to be the first accurate method for tracing a 3D-printed object to the machine it came from.

The advancement, which the research team calls "PrinTracker," could ultimately help law enforcement and intelligence agencies track the origin of 3D-printed guns, counterfeit products, and other goods.

"3D printing has many wonderful uses, but it's also a counterfeiter's dream. Even more concerning, it has the potential to make firearms more readily available to people who are not allowed to possess them," says the study's lead author Wenyao Xu, associate professor of computer science and engineering in UB's School of Engineering and Applied Sciences.

The study includes coauthors from Rutgers University and Northeastern University.

Each layer of a 3D-printed object contains tiny wrinkles—usually measured in submillimeters—called in-fill patterns. These patterns are supposed to be uniform. However, the printer's model type, filament, nozzle size and other factors cause slight imperfections in the patterns. Like a fingerprint to a person, these patterns are unique and repeatable. As a result, they can be traced back to the 3D printer.

"3D printers are built to be the same. But there are slight variations in their hardware created during the manufacturing process that lead to unique, inevitable and unchangeable patterns in every object they print," Xu says.

To test PrinTracker, the research team created five door keys each from 14 common 3D printers—ten fused deposition modeling (FDM) printers and four stereolithography (SLA) printers.

With a common scanner, the researchers created digital images of each key. From there, they enhanced and filtered each image, identifying elements of the in-fill pattern. They then developed an algorithm to align and calculate the variations of each key to verify the authenticity of the fingerprint.

Having created a fingerprint database of the 14 3D printers, the researchers were able to match the key to its printer 99.8% of the time. They ran a separate series of tests 10 months later to determine if additional use of the printers would affect PrinTracker's ability to match objects to their machine of origin. The results were the same.

The team also ran experiments involving keys damaged in various ways to obscure their identity. PrinTracker was 92% accurate in these tests.

Xu likens the technology to the ability to identify the source of paper documents, a practice used by law enforcement agencies, printer companies and other organizations for decades. While the experiments did not involve counterfeit goods or firearms, Xu says PrinTracker can be used to trace any 3D-printed object to its printer.

SOURCE: University at Buffalo; http://www.buffalo.edu/news/releases/2018/10/030.html

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.