Lausanne, Switzerland--In this race for protection of property, EPFL researchers are making their contribution. Even though there has been a wide diversification of protective measures against counterfeits, technological advances in scanning and printing methods simplify the manufacture of several kinds of forgeries such as: banknotes, passports, electronic items, watches, drugs, etc. By combining two complex techniques, EPFL researchers have developed a new authentication system able to create images virtually impossible to reproduce. Their invention was published in Light, a new magazine associated with the Nature Publishing Group and dedicated to research in the field of optics.

Two EPFL research teams, led by professors Roger D. Hersch and Jürgen Brügger, have been able to combine their respective specialties: the moiré pattern technique together with microlithography, a circuit manufacturing technique by engraving at a micrometer scale. They were able to obtain a dynamic and small image that offers an interesting alternative to holograms, which at present are relatively easy to reproduce or modify.

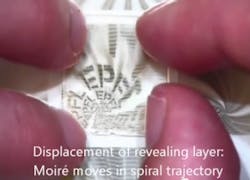

The moiré pattern is a well-known optical phenomenon. It results from interference between two superimposed structures, each consisting of dark and light areas. It occurs if, for instance, we slide two grids placed one behind the other. Or when watching a striped shirt on TV, as the clothing pattern is superimposed to the screen lines.

At the Peripheral Systems Laboratory, Roger Hersch, Sylvain Chosson and Isaac Amidor have developed mathematical models able to describe, replicate and control such a phenomenon. Thus, it is possible to create moiré patterns by scrolling designs or letters, undetectable if the two layers are not superposed. They have also been able to perform polychromatic, wavy or curved moiré patterns.

Used for several years in the fight against counterfeiting, moiré patterns are also used in bank notes such as the 1000 Swedish crowns or the 100 Mexican pesos. EPFL researchers are now using them in an entirely different way.

Firstly, despite their small size (about 0.5 x 0.5 cm), the patterns are easily recognizable by the naked eye. Therefore, a lamp or infrared microscope is not required for testing their authenticity. Besides, the method offers the possibility to obtain complex and high resolution images: of nearly 10,000 dpi, whereas the most efficient printing machines can only go up to an effective resolution of 1200 dpi. Changing only a few microns in the superposition of the two layers composing the pattern would provoke a significant deformation. Thus, all manipulations are easily identifiable.

The manufacturing process has been developed by Victor Cardarso and Jürgen Brugger at the Microsystems Laboratory. They use equipment specifically designed for nanostructures. The base layer patterns are made with a thin layer of gold. For the upper layer, an assembly of microlenses (measuring 50 microns each) is used. "We have developed a protocol for complex manufacturing, which requires extreme precision in terms of the diameter, curvature and casting of the lenses, explains Jürgen Brügger. In this way, such patterns are simply impossible to imitate through traditional printing systems." As for the future, the researchers plan to refine their procedure and to test on different types of models made with other materials and integrating the use of colors.

SOURCE: EPFL; http://actu.epfl.ch/news/a-micro-optical-method-for-thwarting-counterfeitin/

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.