Exotic phase of germanium could be better for IR photodetectors than ordinary Ge

Germanium (Ge) has uses in photonics by itself as a detector material, and also as a material used along with silicon (Si) to create SiGe passive and active photonics devices including optical switches, photodetectors, and thermal imaging arrays.

An interesting area of research is the creation of forms of Ge synthesized in the lab under extreme pressure conditions. However, one of the most-promising forms of exotic Ge potentially useful for practical applications, called ST12, has only been created in tiny sample sizes—too small to definitively confirm its properties.

"Attempts to experimentally or theoretically pin down ST12-germanium's characteristics produced extremely varied results, especially in terms of its electrical conductivity," says Zhisheng Zhao, a researcher at the Carnegie Institution for Science (Washington, DC) and the first author on a new paper about this form of Ge.

The study’s research team, led by Carnegie’s Timothy Strobel, was able to create ST12-Ge in a large-enough sample size to confirm its characteristics and useful properties.1

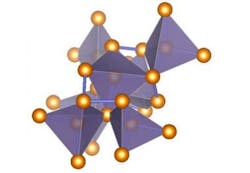

ST12-Ge has a tetragonal structure; the name ST12 means "simple tetragonal with 12 atoms." It was created by putting germanium under a pressure of 14 GPa, or about 1.38 x 105 atmospheres, and then decompressing it slowly at room temperature.

The millimeter-sized samples of ST12-Ge that the team created were large enough that they could be studied using a variety of spectroscopic techniques to confirm its long-debated characteristics.

Indirect bandgap

Like Si and like the most common diamond-cubic form of Ge, they found that ST12 is a semiconductor with an indirect bandgap. While direct-bandgap materials can emit light and very effectively absorb it, indirect-bandgap materials cannot.

"Our team was able to quantify ST12's optical bandgap—where visible light energy can be absorbed by the material—as well as its electrical and thermal properties, which will help define its potential for practical applications," Strobel says. "Our findings indicate that due to the size of its bandgap, ST12-germanium may be a better material for infrared detection and imaging technology than the diamond-cubic form of the element already being used for these purposes."

Source: https://carnegiescience.edu/node/2125

REFERENCE:

1. Zhisheng Zhao et al., Nature Communications (2017); doi: 10.1038/ncomms13909

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.