New photon-detection material has high detection efficiency, less jitter

Researchers at the National Institute of Standards and Technology (NIST; Boulder, CO), the University of Geneva (Geneva, Switzerland), and the Jet Propulsion Laboratory (JPL), California Institute of Technology (Pasadena, CA) are creating superconducting nanowire single-photon detectors (SNSPDs) made of a new material, molybdenum silicide (MoSi), which leads to both a high system detection efficiency (87.1 ±0.5% at 1542 nm) at 0.7 K and a minimum system jitter of 76 ps -- half that of the previous record of about 150 ps.1 As a result, quantum communications can happen at a higher bit rate, with more information transmitted in the same time period.

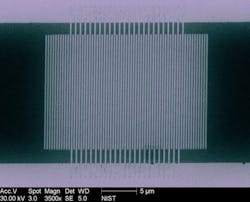

An electron beam was used to pattern nanowires into a thin film made of MoSi.

The new detectors can also be operated with saturated internal efficiency at a temperature of 2.3 K. The new design improves on NIST’s 2011 tungsten-silicon alloy material because it can operate at higher (though still cryogenic) temperatures and at a higher electrical current. The higher temperature simplifies refrigeration, while the higher current cuts jitter in half. NIST researchers enhanced the detector’s light absorption and efficiency by embedding the chip in a cavity made of gold mirrors and layers of other unreactive materials.

The 87% efficiency of the MoSi device is almost as high as that for tungsten-silicon devices (93%) but with significantly lower jitter.

Development of next-generation sensors offering high precision is a NIST priority. NIST single-photon detectors are used in a variety of experiments around the world.

Source: NIST

REFERENCE:

1. V. B. Verma et al., Optics Express, Vol. 23, Issue 26, 2015; doi: 10.1364/OE.23.033792

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.