Highly conductive graphene ink opens door to screen-printing for flexible displays

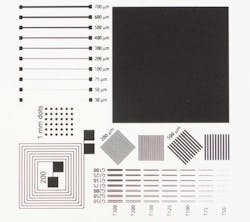

A screen-printable functionalized graphene ink supplied by Goodfellow (Coraopolis, PA) performs better than normal carbon-based ink, according to the company, which says the new ink will enable applications that require exceptional electrical conductivity, excellent ink coverage, and high print resolution, including lightweight flexible displays, organic LEDs (OLEDs), thin-film photovoltaics, sensors, plastic electronics, and others.

Goodfellow supplies metals, polymers, ceramics and other materials for science and industry. The company specializes in supplying small quantities (a few grams to a few kilos) of metals and materials for research, prototype development, and specialized manufacturing applications.

The ink is made with functionalized graphene nanoplatelets and is optimized for the viscosity and solid contents required of semi-automatic and manual screen-printing equipment. Substrates that can be printed include but are not limited to polymers, ceramics, and papers.

Functionalized graphene ink is flexible on appropriate substrates, metal-free and 100% organic (nontarnishing), curable at low temperatures, and environmentally friendly, says Goodfellow. The ink can be modified for specific applications.

Scientists and printers running trials with the small quantities available from Goodfellow (100 g to 1000 g) can, if desired, consult with Goodfellow to further tailor performance of the ink to meet individual needs.

For more information about functionalized graphene ink, see www.goodfellowusa.com.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.