LWIR cameras are the powerhouse behind thermal imaging

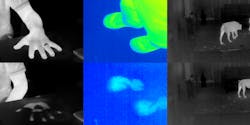

Thermal imaging of objects at or near room temperature is typically done in the 8–14 μm longwave-infrared (LWIR) spectral band, as the Planck curve for blackbody radiation for room-temperature (300 K) objects peaks in the LWIR at about 9 μm. LWIR imaging has the great advantages of being able to image objects by their own light and discriminate between objects based on their temperature; in addition, LWIR imaging works well for outdoor use due to the relatively low output power of the Sun at LWIR wavelengths.

The most widely used sensor type used in LWIR imaging, and the one most covered in this article, is the uncooled bolometer focal-plane array (FPA), which is usually (but not always) based on vanadium oxide. The list of applications for LWIR imaging is extensive, and includes many uses in surveillance and security; biology, geology, and other sciences; industrial inspection and process control; and medical and veterinary fields. This article provides a bit of background on some commercial examples of current LWIR imagers.

Small-pixel imagers

Leonardo DRS (Arlington, VA), which produces uncooled vanadium oxide microbolometer FPAs, camera modules, and camera systems for military and commercial markets, has developed a line of small-pixel (10 μm pitch) arrays to complement its line of 17-μm-pitch arrays, as described by Doug Ransom, VP of Leonardo DRS’ Electro-Optical and Infrared Systems business. Its 1-μm-pitch arrays, including the U6800 (640 × 512) and the U9000 (1280 × 1024) FPAs, are the sensors for the company’s Tenum 640 and Tenum 1280 camera modules as well as for cameras used in several U.S. military programs. DRS’s 17-μm-pitch arrays, including the U3600 (320 × 240), U6160 (640 × 480), and U8000 (1024 × 768) FPAs, are the sensors in the company’s Tamarisk family of camera modules as well as various other DRS system-level products.

“The most recent DRS advances in pixel design and process improvements allow reductions in pixel size while still achieving desired performance levels,” says Ransom. “This performance is crucial when reducing pixel size because reductions in size typically sacrifice sensitivity. DRS employs a patented umbrella pixel design that separates the radiation-absorbing and transducing elements of the bolometer. This separation allows for a maximum focal-plane fill factor, and the unique umbrella structure design reduces the mass and thermal time constant of the bolometer.”

DRS will begin volume production of the Tenum 640 thermal imaging module in the fourth quarter of 2020; Ransom notes that the module is the first uncooled (640 × 512) 10-μm-pitch thermal camera module on the market available for original equipment manufacturers (OEMs).

To simplify integration for OEMs, the module is I/O-compatible with the Tamarisk products, using the same connector and feature board. In addition, the communication protocol is the same, so OEM customers can plug a Tenum 640 into their current products and begin imaging and controlling the camera without extensive engineering changes.

Since 2014, DRS uncooled camera modules have been used in handheld firefighting cameras, says Ransom. “Uncooled LWIR cameras give firefighters the ability to see clearly through smoke, locate and rescue victims, and identify dangerous hot spots,” he explains. “With the radiometric (temperature measurement) capability of the DRS LWIR camera module, a firefighter can determine the temperature of a ceiling or door before encountering a dangerous building collapse or entering a dangerous room.” The firefighter’s task is made easier by DRS’s Image Contrast Enhancement (ICE) algorithm (see Fig. 1).

Remote temperature measurement, including of humans

Jenoptik (Jena, Germany), which includes Jenoptik Optical Systems (Jupiter, FL), has multiple product lines of thermal imagers; its current products include the IR-TCM camera, VarioCAM handheld camera, and Blackbird Precision portable monitoring kit, which have all been designed and are calibrated to visualize heat and detect temperature anomalies in either mobile or stationary applications. In addition, Jenoptik is introducing a new line of compact uncooled thermal camera modules called EVIDIR in 2020.

The company’s thermographic camera product line is based on VGA and XGA 17 μm amorphous silicon (A-Si) microbolometer technology, whereas the new EVIDIR products are built around VGA and QVGA 12 μm A-Si microbolometers. All of Jenoptik’s thermal cameras offer a variety of standard configuration options such as camera format, frame rate, communication interface, and lens options. “The cameras are fully functional as stand-alone devices, but IR-TCM, Blackbird, and EVIDIR have been designed to facilitate integration into OEM applications,” says G. Scott Libonate, North American director, Advanced Systems, at Jenoptik Optical Systems. “All of the OEM cameras and, in particular, the EVIDIR offer a ‘toolbox’ approach of available configuration options to facilitate OEM customization: options such as lenses, shutter, imager format, frame rate, and communication interface are modular, allowing customers to mix and match to best suit their applications.”

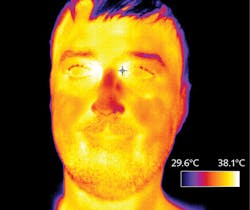

Libonate notes that all of Jenoptik’s thermal cameras have a high sensitivity with a temperature resolution (NETD) less than 40 mK, which allows them to distinguish relative temperature differences of a tenth of a degree or less (see Fig. 2). He adds that thermographic cameras like the Blackbird can remotely measure temperatures with an absolute accuracy of better than 2°C over a -40°–600°C temperature range (with high-temp calibration options up to 1200°C available).Applications include safety and security (surveillance, search and rescue, firefighting, border control, situational awareness, UAV), automotive (advanced driver-assistance systems, autonomous driving), and industrial automation (process control, predictive maintenance, fault condition detection), according to Libonate. The Blackbird is specifically designed for remote temperature measurement in industrial applications such as process monitoring, failure detection, and thermal screening, and can be purchased with a thermal monitoring kit that includes camera, tablet, and a visualization, analysis, and recording software package.

“These features have recently been put to good use in response in the COVID-19 pandemic,” Libonate notes. “While not specifically intended to be a medical device, the Blackbird was re-calibrated and software modified to optimize its ability to detect human body temperature at the entrance to Jenoptik’s Jena Germany facility. The screening station is now used to check all Jenoptik employees for fever before they enter the facility.”

Thixomolding, wafer-scale optics

OEM uncooled camera models produced by FLIR Systems (Wilsonville, OR) are based on vanadium oxide microbolometer detectors, with numerous detector array formats and lens options available, depending on the application requirements. According to the company’s engineers, FLIR was the first thermal camera company to use magnesium thixomolding (beginning with its Tau models) for the resulting lightweight, yet strong and low-cost camera housings. In an interesting application of wafer-scale optics technology, FLIR’s low-cost Lepton microthermal camera has a wafer-formed fixed-focus lens and custom ASIC that performs all camera functions in a single chip, which makes possible a very small module designed for integration into mobile devices and consumer electronics.

The company’s Tau cameras use a common camera frame to incorporate either a 336 × 256 or 640 × 512 sensor (with 17 μm pixels) to reduce manufacturing costs (see Fig. 3). Two lens holders, one for wide-field optics and the other for narrow-field, allow the use of a range of interchangeable lenses. The camera is available as either a radiometric or nonradiometric imager. (For a radiometric imager, processing and calibration are used to produce an output value that is linearly proportional to scene temperature.)The low-cost Lepton microthermal camera, with its wafer-formed fixed-focus lens and custom ASIC, has a miniature micromodule designed for interfacing into mobile devices, consumer electronics, and both commercial and industrial Internet-of-things (IoT) devices. The Lepton camera comes in two 160 × 120 models (one of which is radiometric), and one 80 × 60 radiometric model.

Finally, the Boson sensor is a 12-μm-pixel design that uses wafer-level packaging (WLP) to support high-rate, lower-cost production. Boson electronics have a system-on-a-chip with an ultralow-power vision-processing core with a large set of built-in I/O for integration with peripheral devices such as displays, SD cards, GPS, and USB interfaces. Applications include integration into handheld thermal-imaging systems such as those used by fire service, thermography, security and surveillance, unmanned systems, and automotive driver vision-enhancement devices, to name a few. Like the Tau camera, Boson can be had with two different sensor formats (320 × 256 and 640 × 512) and a variety of lens options.

Two types of sensors

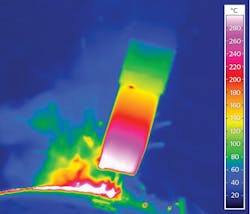

Two quite different types of LWIR thermographic (meaning fully radiometric) cameras produced by InfraTec (Dresden, Germany) serve low- and high-speed imaging purposes. The company’s VarioCAM HD series consists of uncooled microbolometer detectors, while its higher-speed ImageIR series is composed of cooled mercury cadmium telluride (MCT) photon detectors (see Fig. 4).As described by Jens Vogt, head of international sales at InfraTec, the VarioCAM HD head 900 camera has a microbolometer detector with XGA (1024 × 768) pixel resolution, is fully radiometric over a range of -40 to 2000°C, and has a thermal sensitivity that reaches 20 mK. “A wide range of applications benefits from those specifications,” says Vogt. “One of these is additive manufacturing, where process parameters need to be precisely set based on respective temperature measurements. Here, the camera’s subwindow ranges allow imaging at higher process speeds of up to 240 Hz.”

For higher speeds, Vogt notes that InfraTec advises the use of its ImageIR MCT-based cameras (for example, the ImageIR 8800, with a spectral range of 7.7 to 10.2 μm, has a frame rate of up to 14,593 Hz). “As all of InfraTec’s cameras come with a wide range of lenses and specific protective windows, additive-manufacturing processes of different scales can be equipped to optimize for the very high demands in spatial resolution,” Vogt adds.

High dynamic range without gain reduction

As part of its infrared imaging portfolio, Teledyne DALSA (Waterloo, ON, Canada) produces powerful, versatile solutions from SWIR to uncooled LWIR for industrial, security, and defense applications. LWIR imagers produced by Teledyne DALSA include its Calibir GXM LWIR cameras containing uncooled IR microbolometer sensors with radiometric operations, the Calibir DXM640 LWIR camera with an uncooled IR VGA camera core, and LWIR wafer-level-packaged vanadium oxide microbolometers.

The Calibir GXM cameras have high sensitivity in the 8–12 µm spectral range and factory-calibrated radiometric performance, according to Jean Brunelle, product manager for the Calibir series. The cameras also feature both shutter and shutterless operation and rapid image output on power-up while delivering uniform response over their whole operating temperature range, all of which benefit uninterrupted image acquisition; a 21-bit ADC design maintains a high dynamic range without the need for gain reduction, leading to the best possible NETD over a temperature range of more than 600°C.

“Calibir delivers accurate, repeatable results for critical applications like detecting elevated skin temperature in fever screening (see Fig. 5),” says Brunelle. “In addition to fever screening, the Calibir GXM series benefits many other industrial monitoring applications requiring radiometric measurement, such as welding, sintering, baking, smelting, and firefighting.”LWIR for firefighting

Longwave-infrared FPAs made by Sierra-Olympic Technologies (Hood River, OR) have “open-frame” (accessible for easy customization) camera cores with electronics, firmware, fixed-focal-length, or continuous optical zoom lenses and software to form small, light, low-power devices that are well suited for OEMs and integrators.

“The Vayu HD is Sierra-Olympic’s flagship LWIR camera,” notes Adam Lapierre, marketing manager at Sierra-Olympic. “With a full HD 1920 × 1200 12 μm vanadium oxide microbolometer array, the Vayu is the highest-resolution uncooled LWIR camera on the market. Weighing about a pound and compact enough to fit in the palm of your hand, it is optimized for integrators, particularly in aerial applications, looking for a SWaP-optimized package that delivers the best imagery at the highest resolution possible.”

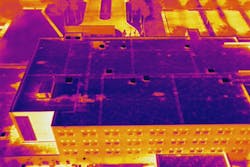

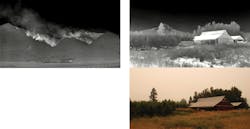

One use for the Vayu that hits close to home for Sierra-Olympic is wildfire monitoring and reconnaissance, says Lapierre. When fast-moving wildfires sweep through an area, they can be difficult to track and map accurately due to dynamic wind and weather conditions, varying terrain, smoke, and other factors (see Fig. 6). Fires tend to “lay down” at night, when winds calm and relative humidity increases; this is often the best opportunity for teams to get an idea of where the hottest spots are, how the fire perimeter evolved during the day, and, most importantly, where to focus efforts the following day.“This is where thermal imaging cameras make an enormous difference,” says Lapierre. “When a blanket of smoke covers the fire area, which it often does at night, a visual survey isn’t all that helpful. A camera like the Vayu HD, however, sees through heavy smoke as if it wasn’t there. Adding to that, a distinct advantage of the Vayu over other thermal cameras is its significantly higher resolution. Being able to capture more detail over a wider area makes a huge difference in the quality of imagery and information that can be presented to crews who will be on the front lines the following day.”

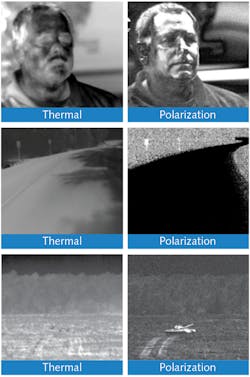

Polarized thermal imaging

While thermal imaging has many capabilities, Polaris Sensor Technologies (Huntsville, AL) produces a LWIR imager that adds to these capabilities via the use of polarization and a miniaturized camera size. Called the Pyxis, the camera is a small (2-cubic-inch), lightweight (83 g) LWIR polarization imager that measures both the thermal and polarization content of an image. The use of polarized light reveals detail, contrast, and other data that remain undetected by standard thermal imaging devices (see Fig. 7).Using a 640 × 512 uncooled vanadium oxide microbolometer FPA, the camera includes tools for image postprocessing via its Pyxis Vision Science software. According to Polaris, the use of polarization can add range, increase contrast, improve specificity, and provide details not delivered by standard thermal imaging alone. For example, polarization-based LWIR cameras can detect contrast even when there is no thermal contrast. The addition of polarization to standard thermal exploits geometry and material composition to improve contrast and detail.

For More Information

Companies mentioned in this article include:

FLIR Systems

Wilsonville, OR

InfraTec

Dresden, Germany

Jenoptik

Jena, Germany

www.jenoptik.com and www.jenoptik.us

Leonardo DRS

Arlington, VA

Polaris Sensor Technologies

Huntsville, AL

Sierra-Olympic Technologies

Hood River, OR

Teledyne DALSA

Waterloo, ON, Canada

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.