Laser 2019: Cutting-edge lasers within a cooling economy

The feelings in the trade-show halls were positive, although noting an economic slowdown. Laser giants IPG and Coherent saw their stock plunging more than 25% in May after they published significant downturns in their revenues. Local champion Trumpf has not shown any numbers yet, but the company’s CEO Nicola Leibinger-Kammüller expected a downturn last year already. “There are increasing signs that this long phase of recovery could soon be over,” she noted. And the German mechanical engineering industry just published a warning of production decline.

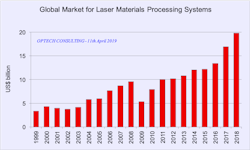

Those who wanted to see a detailed picture of the laser economy went to laser market analyst Arnold Mayer and his Laser Marketplace workshop in Munich. He showed that the market for laser materials-processing systems grew by an incredible 50% from 2016 to 2018. Any outlook for 2019 is difficult: “Maybe we are lucky and will get out with zero growth,” he said during his workshop. But looking back over the last 20 years, he sees no reason why long-term growth between 7% and 9% should not continue. If global economic growth picks up, he expects better figures as early as 2020.

Better, bigger, and blue laser systems

As the name of the trade show suggests, it is a good place to showcase new laser systems. Those who think that laser development is not hot anymore had a chance to learn many new things. The hottest topic in recent months was certainly the development of ultrafast (ultra short pulsed) lasers with high average power. While all major laser manufacturers offer systems with about 50 W average power, it was a small company from Jena, Germany, Active Fiber Systems, that unveiled a record-breaking 2 kW ultrafast laser: This device delivers 20 mJ pulses at 100 kHz in 200 fs pulses using a fiber-based technology developed by a team headed by Jens Limpert from the Friedrich Schiller University Jena. It is the same technology that will soon be available in applications labs in Jena and Aachen from the Fraunhofer Cluster of Excellence Advanced Photon Sources.

And there is another field in which progress is far from ended: Diode lasers. Paul Crump just recently wrote about laser diode research in Laser Focus World. In Munich, he and some colleagues from Ferdinand-Braun-Institut (FBH; Berlin, Germany) reported a new record at the CLEO Europe conference. The team created the brightest and most efficient kilowatt bar ever reported with an efficiency >65% at 1 kW, and also the narrowest lateral far field of 8.8°. The research was done in close cooperation with the Trumpf laser group.

Alternatively, one could use blue diode lasers as presented by Christoph Ullmann of Laserline (Mülheim-Kärlich, Germany) at the main press conference of the trade show. With funding from the German government, Laserline participated in the BlauLas project (together with Osram Opto Semiconductors and Dilas) in which blue laser diode modules were developed with kilowatt power. The advantages for copper processing are comparable to the green lasers, except that diode lasers have higher efficiency and lower beam quality.

Trends in e-mobility and beyond

E-mobility was certainly the biggest trend on the show. I counted at least three electrical vehicles presented in the halls to highlight the multitude of things one can do with lasers in the manufacturing of electrical cars and their components. Nevertheless, I found two more trends to be remarkable and less obvious.

The first trend to mention regarding industrial laser applications is process control. Take battery welding: Every seam has to be tight. To be safe, you'd better track and record every single weld seam; to be efficient in this, you may want to consider inline process control to see every small change immediately. Interestingly, it looks as if process control is now a feature that separates the premium laser processing systems from the low-cost systems. It is here where the money is made.

A second, and even less obvious, trend was explained to me by Dirk Hauschild from LIMO. “After laser-optimized engineering became common practice, it is now time to consider laser-optimized materials,” he told me. A simple example is already well known: Laser annealing of amorphous silicon is a process in which the laser changes a material and enables it to show very useful properties. Of course, the secret here is the right beam shape, created by advanced micro-optics.

Another example is metal powders for additive manufacturing: If you know how they behave in the build-up process, you can select the right material according to your laser process. Some processes are well-known, but it takes the joint efforts of laser physicists, material scientists, and mechanical engineers to use the full potential of this process. There could be plenty of reward for such an effort: What if a laser could help to make much more efficient battery materials?

And more…

Four days and five halls plus a congress with seven separate conferences made it a tough challenge to follow all activities. While one of the most influential persons in the German laser community, Reinhart Poprawe, was given a farewell colloquium on the eve of the LASER fair, a new generation with new ideas was welcomed in the days following: For example, a “makeathon” and a startup challenge draw a lot of attention from the younger visitors. Those with new ideas had a chance to meet with VCs at the European Photonics Venture Forum.

Trade-show organizer Messe München and the German high-tech industry association spectaris presented a study on how photonics can help in protecting the Earth’s climate: Photonic technologies help to reduce carbon emissions and to establish alternative energy-generation methods. In exemplary calculations, they found that photonics will help to save 3 billion tons of CO2 emissions in 2030.

Climate change was quite obvious in Munich: Most of the recent years it has been hot, but this year the outside temperature hit a new record of 39°C. That didn't stop people from taking advantaged of another important part of the trade fair program—the booth parties. Tuesday night a new party giant took over leadership in this challenge: Hübner Photonics convinced with a well-filled dance floor and lots of beer. Tough competition for the longtime party champion Toptica Photonics!

The next Laser World of Photonics will be held June 21 – 24, 2021, in Munich, Germany.

About the Author

Andreas Thoss

Contributing Editor, Germany

Andreas Thoss is the Managing Director of THOSS Media (Berlin) and has many years of experience in photonics-related research, publishing, marketing, and public relations. He worked with John Wiley & Sons until 2010, when he founded THOSS Media. In 2012, he founded the scientific journal Advanced Optical Technologies. His university research focused on ultrashort and ultra-intense laser pulses, and he holds several patents.