Writing about extreme fiber-optic bandwidth for the February 2014 issue brought to mind a paper from the first Optical Fiber Communications meeting I attended in March 1979. S. Inao of Furukawa Electric (Tokyo, Japan) made a 480 m fiber containing seven distinct cores, one in the center and the other six spaced around it. They had inserted seven fiber preforms into a glass tube, fused the tube to the preforms, and then drew it into a single multicore fiber. They reported crosstalk between cores of 43 dB, with average attenuation of 3 dB/km at 850 nm.

It was an intriguingly bold idea mentioned on the first page of my OFC preview in the March 1979 Laser Focus (page 34). But the big news at the meeting, reported on page 74 of the May 1979 issue, was record-low attenuation of 0.2 dB/km at 1.55 µm reported by Nippon Telegraph and Telephone's Electrical Communication Laboratory (Ibaraki, Japan). Bell Labs (Holmdel, NJ) reported "no measurable pulse spreading" when sending 5 ps pulses at 1.32 µm through a 760 m length of single-mode fiber, experimental confirmation of the zero-dispersion wavelength in standard single-mode fiber. And Robert Gallawa of the National Telecommunications and Information Administration (Boulder, CO) predicted "imminent" use of fiber systems operating above 100 Mbit/s.

Furukawa's bold idea was packing many cores into a single fiber to enhance capacity, but their cores were multimode and they were looking to replace the graded-index multimode fibers that were standard in first-generation fiber-optic systems. Like the rest of the young fiber-optic establishment, they expected multimode fibers to dominate the market for many years. But within three years, 400 Mbit/s singlemode systems were being installed in the long-haul backbone network and single-mode transmission soon dominated the market. I relegated multicore fibers to my mental file of intriguing but impractical ideas.

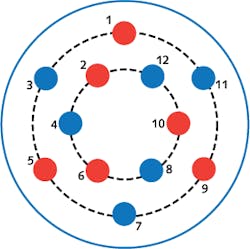

Now multicore fibers are back, as wavelength-division multiplexing and coherent transmission in single-mode fibers start to bump against the fundamental limits set by information theory and signal-to-noise ratio. Automated techniques have been developed to splice multicore fibers. One recent hero experiment sent 818 Tbit/s through a 450 km length of 12-core fiber. Like Inao and colleagues nearly 35 years ago, today's developers of multicore fibers hope to reduce costs by integrating transmission through multiple paths within the same fiber.

Plenty of challenges remain. We're talking hero experiments rather than field trials or system deployments. But keep an eye on those crazy ideas that seem impractical. Technology has a way of catching up with them. What other examples can you think of?

About the Author

Jeff Hecht

Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.