ULTRAHIGH-DATA-RATE FIBER: Multicore fiber transmits 818 Tbit/s over 450 km

A team of primarily Japanese engineers led by Akihide Sano of NTT Corporation (Yokosuka, Atsugi, and Tsukuba, Japan) has demonstrated transmission of data over a 450 km section of multicore optical fiber at rates that approach a petabit per second.1 The 12-core double-ring-structure fiber is designed for bidirectional use, with six cores devoted to transmission in each direction; a transmission rate of 409 Tbit/s in each direction was achieved, for a total of 818 Tbit/s.

Other members of the team are from Fujikura, Hokkaido University, Osaka Prefecture University, Shimane University, and Technical University of Denmark. Before obtaining these newest results, the same group had done an earlier test using a single-ring-structure 12-core fiber; that design had the two disadvantages of smaller core effective areas and higher intercore crosstalk.

Propagation-direction interleaving

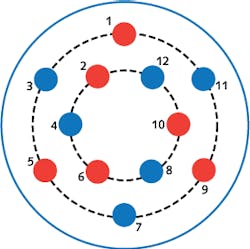

The multicore fiber has two rings of cores (see figure), with the individual cores interleaved so that they alternate in propagation direction—called propagation-direction interleaving (PDI). This is one of the most important elements of the design, as it suppresses intercore crosstalk (a core near another core whose signal is traveling in the opposite direction will not introduce crosstalk into that core).

The cores each have a large effective area of 105.8 μm2; the diameter of the resulting 12-core fiber is 230 μm. The transmission system includes a multicore erbium-doped fiber amplifier (EDFA). At the transmission end, light from 406 continuous-wave lasers, each phase-modulated, was combined via dense wavelength-division multiplexing (DWDM) for each core, filling the spectral range of 1526 to 1615 nm with signals spaced 25 GHz apart. Each EDFA core was pumped with 980 nm forward-pumping and 1480 nm backward-pumping, and included a gain flattening filter at its output. Average loss of the optical fiber was 0.186 dB/km. Fan-in and fan-out devices were used to get light into and out of the 12-core fiber.

On the receiving end, signals were demultiplexed using a 50 GHz tunable optical filter and detected with a polarization-diversity intradyne coherent receiver, with the signals digitally postprocessed. When tested with all signals traveling the same way (unidirectional transmission), the resulting intercore crosstalk was -40.3 dB at a 1613 nm test wavelength; using PDI, this figure was reduced to -44.3 dB (at shorter wavelengths around 1540 nm, these figures approached -45 and -50 dB, respectively).

Twelve-core, 406-channel WDM transmission was demonstrated over 450 km of fiber; the Q factors for all 406 channels for all 12 cores were better than 5.8 dB, which exceeded the 5.7 dB lower limit required for efficient operation of the layered decoding algorithm (including a 20% overhead). (The Q factor is the average bit-error ratio of demodulated signals for six different polarization states.) Net spectral efficiency of the transmission per core was 6.72 bit/s/Hz.

The researchers note that the 450 km transmission distance is about nine times further than any previously attained for experiments at ultrahigh-data-rate transmission speeds of more than 300 Tbit/s.

REFERENCE

1. A. Sano et al., Opt. Exp., 21, 14, 16777 (2013).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.