IR imaging, computer simulation combine to improve breast cancer detection

Researchers at the Rochester Institute of Technology (RIT) and physicians from the Rochester Regional Health System (RRHS; both in Rochester, NY) have developed a noninvasive process using infrared (IR) imaging and computer simulation to better detect breast cancer, making it more comfortable and reliable than existing methods. The work is being led by Satish Kandlikar, professor of mechanical engineering in RIT’s Kate Gleason College of Engineering, who has been involved in advancing thermal imaging technology since the 1990s.

Current patients in the Rochester Regional Health Breast Center volunteer to be tested after an initial mammography that shows suspicious findings on x-ray films. When referred for a follow-up MRI, these patients can also volunteer to be screened using the IR imaging system.

"Thermography is definitely not a new technology, it has been around for a long time," says Alyssa Recinella, an engineering doctoral student and a member of Kandlikar's research team. "The reason people are so interested in it is because it does not induce radiation like mammography does, there is no contrast material, like you have with an MRI. It is more comfortable. Patients will not need to be contorted into different positions or smash anything. It is completely noninvasive."

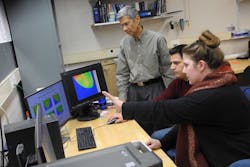

The system consists of an IR camera on a track mounted underneath a cushioned table with a hold in its center. It is angled and can be adjusted as the clinician moves it to take images. Recinella works closely with the team of breast cancer experts at the RRHS center—from oncologists and radiologists to researchers and sociologists—on testing and in helping interpret medical information.

Thermography studies have been done in the past, but the technology today is more sensitive and it is through these advancements that the RIT team has been able to show far more detail in images and validate tumor locations. The IR test takes 20 minutes compared to an MRI, which may take up to 45 minutes.

"Current screening modalities rely heavily on digital mammography, but this technique has shortcomings, particularly in the significant subset of women who have dense breast tissue," explains Pradyumna Phatak, medical director of the Lipson Cancer Institute and chief of medicine. "Infrared imaging using our technique is easy, quick, noninvasive, and cost-effective. Our preliminary data suggest that it may be a very sensitive adjunct to routine screening mammography. Further studies are needed to decide the best way to utilize this technology in practice."

Taking the images is only one part of the process: the team is also using advanced computer simulation technology to do predictive analysis on tumor locations and growth. This is similar to artificial intelligence, where computing systems can 'learn' to aid diagnosis. Acquiring data about tumor types, size, progression of growth, and locations can help physicians assess advancement of disease and determine interventions. Data acquired is based on a highly scientific approach employing advanced mathematical tools, says Kandlikar.

"We believe that our approach will provide a cost-effective and reliable adjunctive tool that is nonradiative and no contact. It is equally effective with dense breast tissue and is well suited to serve remote and underserved populations," Kandlikar says. "It is time it receives the attention it deserves through large-scale clinical studies."

For more information, please visit rit.edu/kgcoe.