Optical ultrasound needle gives high-res view of heart tissue during surgery

A team of researchers at University College London (UCL) and Queen Mary University of London (QMUL) has developed a new optical ultrasound needle that can image heart tissue in real time during keyhole procedures. The technology has been used for minimally invasive heart surgery in pigs, giving a high-resolution view of soft tissues up to 2.5 cm in front of the instrument, inside the body.

Related: Cardiac catheter pairs light, ultrasound to measure plaques

Doctors currently rely on external ultrasound probes combined with preoperative imaging scans to visualize soft tissue and organs during keyhole procedures, as the miniature surgical instruments used do not support internal ultrasound imaging. Recognizing this limitation, the research team designed and built the optical ultrasound technology to fit into existing single-use medical devices, such as a needle.

"The optical ultrasound needle is perfect for procedures where there is a small tissue target that is hard to see during keyhole surgery using current methods and missing it could have disastrous consequences," explains Malcolm Finlay, study co-lead and consultant cardiologist at QMUL and Barts Heart Centre. "We now have real-time imaging that allows us to differentiate between tissues at a remarkable depth, helping to guide the highest risk moments of these procedures. This will reduce the chances of complications occurring during routine, but skilled procedures such as ablation procedures in the heart. The technology has been designed to be completely compatible with MRI and other current methods, so it could also be used during brain or fetal surgery, or with guiding epidural needles."

The team developed the all-optical ultrasound imaging technology for use in a clinical setting over four years. They made sure it was sensitive enough to image centimeter-scale depths of tissues when moving—it fitted into the existing clinical workflow and worked inside the body.

"Using inexpensive optical fibers, we have been able to achieve high-resolution imaging using needle tips under 1 mm," says study co-lead Adrien Desjardins of the Wellcome EPSRC Centre for Interventional and Surgical Sciences at UCL. "We now hope to replicate this success across a number of other clinical applications where minimally invasive surgical techniques are being used."

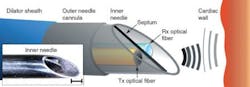

The technology uses a miniature optical fiber encased within a customized clinical needle to deliver a brief pulse of light that generates ultrasonic pulses. Reflections of these ultrasonic pulses from tissue are detected by a sensor on a second optical fiber, giving real-time ultrasound imaging to guide surgery.

One of the key innovations was the development of a black flexible material that included a mesh of carbon nanotubes enclosed within clinical-grade silicone precisely applied to an optical fiber. The carbon nanotubes absorb pulsed laser light, and this absorption leads to an ultrasound wave via the photoacoustic effect.

A second innovation was the development of highly sensitive optical fiber sensors based on polymer optical microresonators for detecting the ultrasound waves. This work was undertaken in a related UCL study led by James Guggenheim (UCL Medical Physics & Biomedical Engineering) and recently published in Nature Photonics.

"The whole process happens extremely quickly, giving an unprecedented real-time view of soft tissue. It provides doctors with a live image with a resolution of 64 µm, which is the equivalent of only nine red blood cells, and its fantastic sensitivity allows us to readily differentiate soft tissues," says study co-author Richard Colchester (UCL Medical Physics & Biomedical Engineering).

The team is now working towards translating the technology for clinical use in patients.

Full details of the work appear in the journal Light: Science & Applications.