IR light-activated gold nanoparticles turn blood clotting on or off

Using gold nanoparticles, Massachusetts Institute of Technology (MIT; Cambridge, MA) researchers have devised a new way to turn blood clotting on and off. The particles, which are controlled by infrared (IR) light from a pulsed femtosecond laser, could help doctors control blood clotting in patients undergoing surgery, or promote wound healing.

Related: Femtosecond laser-driven optical nanotweezers could help cellular-level studies

Related: First viable stroke treatment is aim of infrared device

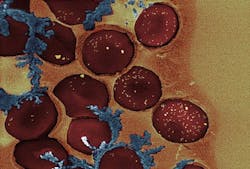

Blood clotting is produced by a long cascade of protein interactions, culminating in the formation of fibrin, a fibrous protein that seals wounds. Heparin and other blood thinners interfere with this process by targeting several of the reactions that occur during the blood-clotting cascade. A better solution, says Kimberly Hamad-Schifferli, a technical staff member at MIT Lincoln Laboratory and senior author of a paper describing the new particles, would be an agent that targets only the last stepâthe conversion of fibrinogen to fibrin, a reaction mediated by an enzyme called thrombin.

Several years ago, scientists discovered that DNA with a specific sequence inhibits thrombin by blocking the site where it would typically bind fibrinogen. The complementary DNA sequence can shut off the inhibition by binding to the original DNA strand and preventing it from attaching to thrombin.

Hamad-Schifferli and her colleagues had previously demonstrated that gold nanorods can be designed to release drugs or other compounds when activated with IR light. The size of the nanorod determines the wavelength of light that will activate it, so two rods of different lengths can carry different payloads and be controlled separately.

To manipulate the blood-clotting cascade, Hamad-Schifferli decided to load a smaller gold nanorod (35 nm long) with the DNA thrombin inhibitor and a larger particle (60 nm long) with the complementary DNA strand. At first, they tried to get the DNA to chemically bond to the gold nanoparticles. However, they found they couldnât load enough DNA onto each particle to make this process effective.

Then, Hamad-Schifferli says, âWe realized we could use a bad side effect of nanoparticle biology to our advantage.â That is, the particles tend to attract a halo of proteins that bind to gold, making them sticky. In previous studies, she has shown that this large cloud of proteins can be used to hold a drug payload. âIf you do that, you can get way more drug on the nanorod than you normally would if you had to chemically link them together,â she says. By soaking the nanorods in a solution of human serum protein and the DNA molecules, the researchers were able to attach six times more DNA than through chemical bonding.

When the gold nanorods are exposed to the correct wavelength of IR light, the electrons within the gold become very excited and generate so much heat that they melt slightly, taking on a more spherical shape and releasing their DNA payload.

The researchers tested the nanoparticles using blood donated to hospitals, and found that the particles successfully turned blood clotting on and off in all of the samples tested. But to make the particles practical for use in patients, they would need to be targeted to the site of injury, which the researchers are now working on doing. Once they reached the site, they would need to be within a few millimeters of the skin surface for the IR light shone on the skin to reach them.

The researchers are also working on modifying the system so the particles can be activated using a continuous-wave (CW) laser, which is smaller and less powerful than the laser they are currently using.

Full details of the work appear in the journal PLoS One; for more information, please visit http://dx.plos.org/10.1371/journal.pone.0068511.

-----

Follow us on Twitter, 'like' us on Facebook, and join our group on LinkedIn

Subscribe now to BioOptics World magazine; it's free!