Novel lensless endoscope produces ultrasmall 3D images of objects

A team of researchers at the Dresden University of Technology (TU Dresden; Dresden, Germany) has developed a self-calibrating endoscope that produces 3D images of objects smaller than a single cell. Without a lens or any optical, electrical, or mechanical components, the tip of the endoscope measures 200 µm across. As a minimally invasive tool for imaging features inside living tissues, the extremely thin endoscope could enable a variety of research and medical applications.

"The lensless fiber endoscope is approximately the size of a needle, allowing it to have minimally invasive access and high-contrast imaging as well as stimulation with a robust calibration against bending or twisting of the fiber," explains Juergen W. Czarske, Director and C4-Professor at TU Dresden and lead author on the paper that describes the work. The endoscope is likely to be especially useful for optogenetics, and could prove useful for monitoring cells and tissues during medical procedures as well as for technical inspections.

Conventional endoscopes use cameras and lights to capture images inside the body. In recent years, researchers have developed alternative ways to capture images through optical fibers, eliminating the need for bulky cameras and other bulky components, allowing for significantly thinner endoscopes. Despite their promise, however, these technologies suffer from limitations such as an inability to tolerate temperature fluctuations or bending and twisting of the fiber.

A major hurdle to making these technologies practical is that they require complicated calibration processes, in many cases while the fiber is collecting images. To address this, the researchers added a 150-µm-thick glass plate to the tip of a coherent fiber bundle, a type of optical fiber that is commonly used in endoscopy applications. The coherent fiber bundle used in the experiment was about 350 µm wide and consisted of 10,000 cores.

When the central fiber core is illuminated, it emits a beam that is reflected back into the fiber bundle and serves as a virtual guide star for measuring how the light is being transmitted, known as the optical transfer function. The optical transfer function provides crucial data the system uses to calibrate itself on the fly.

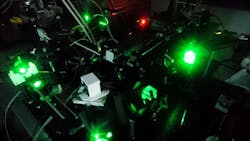

A key component of the new setup is a spatial light modulator, which is used to manipulate the direction of the light and enable remote focusing. The spatial light modulator compensates the optical transfer function and images onto the fiber bundle. The back-reflected light from the fiber bundle is captured on the camera and superposed with a reference wave to measure the light's phase.

The position of the virtual guide star determines the instrument's focus, with a minimal focus diameter of approximately 1 µm. The researchers used an adaptive lens and a 2D galvanometer mirror to shift the focus and enable scanning at different depths.

The team tested their device by using it to image a 3D specimen under a 140-µm-thick cover slip. Scanning the image plane in 13 steps over 400 µm with an image rate of 4 cycles per second, the device successfully imaged particles at the top and bottom of the 3D specimen. However, its focus deteriorated as the galvanometer mirror's angle increased. The researchers suggest that future work could address this limitation. In addition, using a galvanometer scanner with a higher frame rate could allow faster image acquisition.

"The novel approach enables both real-time calibration and imaging with minimal invasiveness, important for in situ 3D imaging, lab-on-a-chip-based mechanical cell manipulation, deep-tissue in vivo optogenetics, and keyhole technical inspections," Czarske says.

Full details of the work will be presented at the Frontiers in Optics/Laser Science 2019 conference, to take place September 15-19 in Washington, DC.