Skin sensor with OLEDs tracks oxygenation of healing wounds in real time

Researchers at the University of California, Berkeley (UC Berkeley; Berkeley, CA) have developed a flexible sensor that uses organic light-emitting diodes (OLEDs) to map blood-oxygen levels over large areas of skin, tissue, and organs, with the goal of giving doctors a way to monitor healing wounds in real time.

The sensor is made of organic electronics printed on bendable plastic that molds to the contours of the body. Unlike fingertip oximeters, it can detect blood-oxygen levels at nine points in a grid and can be placed anywhere on the skin. It could potentially be used to map oxygenation of skin grafts, or to look through the skin to monitor oxygen levels in transplanted organs, the researchers say.

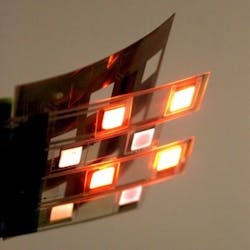

A new sensor made of an alternating array of printed light-emitting diodes and photodetectors can detect blood-oxygen levels anywhere in the body. The sensor shines red and infrared light into the skin and detects the ratio of light that is reflected back. (Image credit: Yasser Khan, Arias Research Group, UC Berkeley)

Existing oximeters use LEDs to shine red and near-infrared (near-IR) light through the skin and then detect how much light makes it to the other side. Red, oxygen-rich blood absorbs more IR light, while darker, oxygen-poor blood absorbs more red light. By looking at the ratio of transmitted light, the sensors can determine how much oxygen is in the blood.

These oximeters only work on areas of the body that are partially transparent, like the fingertips or the earlobes, and can only measure blood-oxygen levels at a single point in the body. "Thick regions of the body, such as the forehead, arms and legs, barely pass visible or near-infrared light, which makes measuring oxygenation at these locations really challenging," explains Yasser Khan, a graduate student in electrical engineering and computer sciences at UC Berkeley.

In 2014, Ana Claudia Arias, a professor of electrical engineering and computer sciences at UC Berkeley, and a team of graduate students showed that printed OLEDs can be used to create thin, flexible oximeters for fingertips or earlobes. Since then, they have pushed their work further, developing a way of measuring oxygenation in tissue using reflected light rather than transmitted light. Combining the two technologies let them create the new wearable sensor that can detect blood-oxygen levels anywhere on the body.

The sensor is assembled from a printed sheet of organic photodetectors (top) and organic red and infrared LEDs (bottom). (Image credit: Yasser Khan, Arias Research Group, UC Berkeley)

The sensor is built of an array of alternating red and near-IR OLEDs and organic photodiodes printed on a flexible material. The team used the sensor to track the overall blood-oxygen levels on the forehead of a volunteer who breathed air with progressively lower concentrations of oxygen and found that it matched those using a standard fingertip oximeter. They also used the sensor to map blood-oxygen levels in a 3 × 3 grid on the forearm of a volunteer wearing a pressure cuff.

"After transplantation, surgeons want to measure that all parts of an organ are getting oxygen," Khan says. "If you have one sensor, you have to move it around to measure oxygenation at different locations. With an array, you can know right away if there is a point that is not healing properly."

Full details of the work appear in the Proceedings of the National Academy of Sciences.