Laser-powered 'needle' promising for pain-free shots

Aiming to take the "ouch" out of drug injections, researchers at Seoul National University (Seoul, South Korea) have developed a laser system that blasts microscopic jets of drugs into the skinâwhich could soon make getting a shot as painless as being hit with a puff of air.

The system uses an erbium-doped yttrium aluminum garnet (Er:YAG) laser to propel a tiny, precise stream of medicine with just the right amount of force. This type of laser is commonly used by dermatologists, particularly for facial aesthetic treatments, says Jack Yoh, professor of mechanical and aerospace engineering at Seoul National University, who developed the device along with his graduate students.

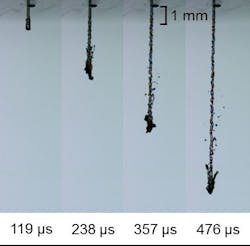

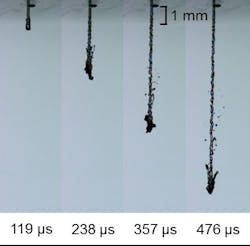

The laser is combined with a small adapter that contains the drug to be delivered, in liquid form, plus a chamber containing water that acts as a "driving" fluid. A flexible membrane separates these two liquids. Each laser pulse, which lasts just 250 ms, generates a vapor bubble inside the driving fluid. The pressure of that bubble puts elastic strain on the membrane, causing the drug to be forcefully ejected from a miniature nozzle in a narrow jet that measures 150 µm in diameter.

"The impacting jet pressure is higher than the skin tensile strength and thus causes the jet to smoothly penetrate into the targeted depth underneath the skin, without any splashback of the drug," says Yoh. Tests on guinea pig skin show that the drug-laden jet can penetrate up to several millimeters beneath the skin surface, with no damage to the tissue. Because of the narrowness and quickness of the jet, it should cause little or no pain, he says. But the researchers are aiming for the epidermal layer, which is located closer to the skin surface, at a depth of only about 500 µm. This region of the skin has no nerve endings, so the method "will be completely pain-free," he says.

In previous studies, the researchers used a laser wavelength that was not well absorbed by the water of the driving liquid, causing the formation of tiny shock waves that dissipated energy and hampered the formation of the vapor bubble. In the new work, Yoh and colleagues use a laser with a wavelength of 2940 nm, which is readily absorbed by water. This allows the formation of a larger and more stable vapor bubble "which then induces higher pressure on the membrane," he explains. "This is ideal for creating the jet and significantly improves skin penetration."

Although other research groups have developed similar injectors, "they are mechanically driven," using piston-like devices to force drugs into the skin, which gives less control over the jet strength and the drug dosage, says Yoh. "The laser-driven microjet injector can precisely control dose and the depth of drug penetration underneath the skin. Control via laser power is the major advancement over other devices, I believe."

Yoh is now working with a company to produce low-cost replaceable injectors for clinical use. "In the immediate future, this technology could be most easily adopted to situations where small doses of drugs are injected at multiple sites," he says. "Further work would be necessary to adopt it for scenarios like mass vaccine injections for children."

The work has been published in Optics Letters; for more information, please visit http://www.opticsinfobase.org/ol/abstract.cfm?URI=ol-37-18-3894.

-----

Follow us on Twitter, 'like' us on Facebook, and join our group on LinkedIn

Laser Focus World has gone mobile: Get all of the mobile-friendly options here.

Subscribe now to BioOptics World magazine; it's free!