OPTICAL DEVICES : The silk road to health and safety

“Biocompatible” and “biodegradable” are terms not usually associated with optical components. But researchers at the Tufts University School of Engineering have created optical elements that exhibit precisely those qualities. The elements, based on silk, promise to form the bases of new sensors that, among other possibilities, could monitor the safety of foods and the levels of key blood chemicals.

“Sophisticated optical devices that are mechanically robust yet fully biodegradable and implantable don’t exist today,” says associate professor of biomedical engineering Fiorenzo Omenetto. “Such systems would greatly expand the use of current optical technologies in areas like human and livestock health, environmental monitoring, and food quality.”

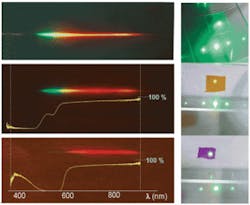

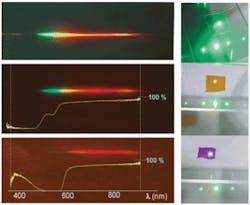

The Tufts group, headed by Omenetto and biomedical engineering professor David Kaplan, report their creations of the devices in Biomacromolecules, First, they boiled cocoons of Bombyx mori silkworms in water and extracted glue-like sericin proteins. They then purified the protein solution and poured it into negative molds of ruled and holographic diffraction gratings. Air drying produced solid fibroin silk films that the team cured in water and dried. Similar procedures produced silk lenses, microlens arrays, and holograms.

The fact that the team prepares the devices in an all-aqueous environment at ambient temperatures ensures that biologic sensors incorporated into the elements at the solution stage remain active once the solution has hardened. The protein hemoglobin, the enzyme horseradish peroxidase, and the organic pH indicator phenol red have all retained their activity for almost a year of storage at room temperature in hardened silk devices.

Innovative uses

The Tufts team envisions several innovative uses for the silk-based technology, on which it has filed several patent applications. “At low cost, we could potentially put a bioactive silk film in every bag of spinach, and it could give the consumer a readout of whether or not E. coli bacteria are in the bag before the food is consumed,” Kaplan explains. The silk-bound sensor would then be harmlessly eaten along with the spinach. The team also imagines using its silk technology in implantable devices that will monitor the blood glucose levels of diabetic patients for several months before dissolving naturally.

Health monitoring devices don’t have to be consumed, however. A team at Switzerland’s Laboratory for Protection and Physiology has incorporated plastic optical fibers capable of tracking blood chemistries into textiles. The team reports in Optics Express that it has created a glove containing a pulse oximeter that monitors arterial blood oxygenation. The glove monitors the blood’s absorption of light at 690 and 830 nm wavelengths.

–PG