Plasmonic nanotweezers trap virus particles without overheating

Engineers at Harvard University (Cambridge, MA) have created a device based on optical tweezers that could isolate and study tiny particles such as viruses easily. Discussed in detail in this month's Nature Communications, the engineeers created plasmonic nanotweezers that use laser light to trap nanoscale particles. The new device creates strong forces more efficiently than traditional optical tweezers and eliminates a problem that caused earlier setups to overheat.

To overcome the limitation of overheating, the engineers developed their plasmonic nanotweezer with an integrated heat sink, says principal investigator Ken Crozier, associate professor of electrical engineering at the Harvard School of Engineering and Applied Sciences (SEAS). The team created the heat sink by replacing the glass with a piece of silicon coated in copper and then gold, with raised gold pillars. These materials are much more thermally conductive than glass, so they act as a heat sink.

"The gold, copper, and silicon under the pillars act just like the heat sink attached to the chip in your PC, drawing the heat away," says lead author Kai Wang (Ph.D. '11), who completed the work at SEAS and is now a postdoctoral fellow at the Howard Hughes Medical Institute.

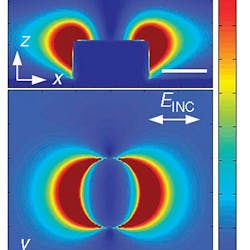

The new device reduces water heating by about 100-fold and produces hotspots at the top edges of the pillars, where Crozier's team was able to trap polystyrene balls as small as 110 nm.

The team also discovered that they were able to rotate the trapped particles around the pillars by rotating the linear polarizer on the optical table where they conducted the experiments. Going further, they replaced the linear polarizer with a circular one and found that the particle automatically and continuously traveled around the pillar.

As the electromagnetic field circled the pillar, it created an optical force that pushed the particle. Despite the fact that the electromagnetic field traveled at about 1,014 rotations per second, the balance between the optical force and the fluid drag resulted in a particle velocity of about 5 rotations per second, effectively a terminal velocity.

As tools for trapping and manipulating nanoparticles become more advanced, the potential applications in biophysics are extensive. One remaining challenge, however, is the researchers' ability to detect and quantify the motion of such tiny particles.

Crozier and Wangâs co-authors were Ethan Schonbrun, a former research associate, and Paul Steinvurzel, a former postdoctoral researcher, both from Crozierâs lab at SEAS. The National Science Foundation, the Defense Advanced Research Projects Agency, and the U.S. Department of Energy all supported this work.

For more information, please visit http://www.nature.com/ncomms/journal/v2/n9/full/ncomms1480.html.

-----

Follow us on Twitter, 'like' us on Facebook, and join our group on LinkedIn

Follow OptoIQ on your iPhone; download the free app here.

Subscribe now to BioOptics World magazine; it's free!