Picosecond laser technique produces synthetic tissue for regenerative medicine

Badly damaged tissue due to disease or an accident prevents the body from being able to regenerate the tissue itself. Recognizing this problem, researchers at the Fraunhofer Institute for Laser Technology (ILT; Aachen, Germany) and other Fraunhofer Institutes developed a picosecond laser technique to produce hybrid biomimetic matrices that allow the body to regenerate itself using the patientâs own cells, replacing natural tissue post-illness or injury.

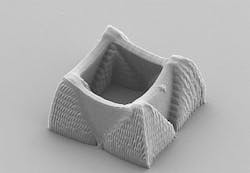

The researchers' process for producing these biomimetic scaffolds that closely emulate endogenous tissue fabricates specialized model systems for the study of 3-D cell growth. They combine organic substances with polymers and produce 3-D structures suitable for building artificial tissue.

As the basis, the researchers used dissolved endogenous proteinsâsuch as albumin, collagen and fibronectinâand biocompatible polymers irradiated with laser light and crosslinked by photolytic processes. To accomplish this, they deployed ultra-short, picosecond laser pulses from a low-cost microchip laser to trigger multiphoton processes, which led to polymerization in the volume. The short pulse duration led to almost no damage by heat to the material. Ultra-fast, megawatt-range pulses drove a massive amount of protons into the laser focus in an extremely short time, triggering a non-linear effect. The molecules in the liquid absorbed several photons simultaneously, causing free radicals to form, which triggered a chemical reaction between the surrounding molecules. As a result of this multiphoton polymerization process, solids formed from the liquid. On the basis of CAD data, the system controled the position of the laser beam through a microscope with a precision of a few hundred nanometers in such a way that micrometer-fine, stable volume elements of crosslinked material gradually formed.

The process enabled the research team to produce scaffolds for cell scaffolds with approximately 1 µm resolution directly from dissolved proteins and polymers, says Sascha Engelhardt, project manager at the ILT. The scaffolds can be seeded with the patientâs own cells in a medical laboratory; then, the colonized scaffolds can be expected to produce good implant growth in the patientâs body. The long-term aim is to use the process to produce not only individual cell colonies, but also complete artificial tailor-made organs.

To optimize their process, the research team wants to greatly increase production speed by combining the fabrication process with other rapid prototyping methods to reduce the time and cost involved in producing tailor-made supporting structures for synthetic tissue.

-----

Follow us on Twitter, 'like' us on Facebook, and join our group on LinkedIn

Follow OptoIQ on your iPhone; download the free app here.

Subscribe now to BioOptics World magazine; it's free!