UV light-reflecting catheter can fix holes in the heart noninvasively

A team of researchers from Boston Children’s Hospital (Boston, MA), the Wyss Institute for Biologically Inspired Engineering at Harvard University (Cambridge, MA), the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS; also in Cambridge), and the Karp Lab at Brigham and Women’s Hospital (also in Boston) have developed a ultraviolet (UV) light-reflecting catheter for fixing holes in the heart using a biodegradable adhesive and patch. The catheter has been used in animal studies to facilitate hole closure without the need for open-heart surgery.

Related: Bio-inspired, light-activated glue could fix heart defects

Pedro del Nido, MD, Chief of Cardiac Surgery at Boston Children’s and contributing author on the study, says that their catheter also avoids suturing into heart tissue because of the device's biodegradable adhesive, which enables gluing the patch in place. The patch then allows for heart tissue to create its own closure, and it will dissolve with time.

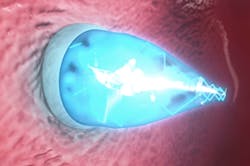

To truly realize the patch’s potential, the research team sought a way to deliver the patch without open-heart surgery. Their newly designed catheter device utilizes UV light technology and can be used to place the patch in a beating heart. The catheter is inserted through a vein in the neck or groin and directed to the defect within the heart. Once the catheter is in place, the clinician opens two positioning balloons: one around the front end of the catheter, passing through the hole, and one on the other side of the heart wall. The clinician then deploys the patch and turns on the catheter’s UV light. The light reflects off of the balloon’s shiny interior and activates the patch’s adhesive coating. As the glue cures, pressure from the positioning balloons on either side of the patch help secure it in place. Finally, both balloons are deflated and the catheter is withdrawn. Over time, normal tissue growth resumes and heart tissue grows over the patch. The patch itself dissolves when it is no longer needed.

"This really is a completely new platform for closing wounds or holes anywhere in the body," says Conor Walsh, Ph.D., contributing author on the study, Wyss Institute Core Faculty member, Assistant Professor of Mechanical and Biomedical Engineering at SEAS, founder of the Harvard Biodesign Lab at SEAS, and author on the paper. "The device is a minimally invasive way to deliver a patch and then activate it using UV light, all within a matter of five minutes and in an atraumatic way that doesn’t require a separate incision."

SEAS/Wyss Institute’s Ellen Roche, Ph.D., co-first author on the paper (along with Boston Children’s Assunta Fabozzo, MD), adds that the device can be customizable. For instance, the rate at which the patch biodegrades can be slowed or accelerated, depending on how quickly the surrounding tissue grows over it. Further studies will reveal the appropriate lengths of time for different circumstances.

Jeff Karp, Ph.D., a bioengineer at Brigham and Women’s Hospital and a co-founder of Gecko Biomedical, developed the glue product in his lab at Brigham and Women’s Hospital. Gecko Biomedical will be testing the glue product in humans later this year.

Full details of the work appear in the journal Science Translational Medicine; for more information, please visit http://dx.doi.org/10.1126/scitranslmed.aaa2406.

Follow us on Twitter, 'like' us on Facebook, connect with us on Google+, and join our group on LinkedIn